High Standard and Good Quality Jch Roofing Metal Steel Roll Forming Machine

Basic Info.

Model NO.

ZK-JCH-001

Tile Type

Colored Steel

Certification

CE, ISO

Condition

New

Customized

Customized

Usage

Roof, Wall, Floor

Transmission Method

Electric

Machine Type

Roll Forming machine

Cutting System

Hydraulic Automatic Cutter

After-Sales Service Provided

Engineers

Raw Material

PPGI PPGL Gi Gl

PLC

Taiida

Profiles

Metal Roof Forming Machine

Use

Steel Construction

Main Frame

350h Steel

Keywords

Colored Steel Roof Making Machine

Cutting Material

Cr12MOV

Transport Package

Naked

Specification

8000*1200*1400mm

Trademark

ZHONGKE

Origin

Botou

HS Code

8455221000

Production Capacity

30sets/Month

Product Description

Product DescriptionJCH in color steel plate refers to a specific design of the edge of the plate, that is, a specific bending or folding angle.

This design can increase the strength and structural stability of the color steel plate, while also helping to prevent

rainwater and other external factors from invading, ensuring durability during use.

Product Parameters

| Roller flatting system | let the feeding fluently |

| Size | 8000mm*1200mm*1400mm |

| Machine under frame | 300H-beam |

| Sidewall plate thickness | 16mm |

| Shaft diameter | 70mm |

| Main shaft material | 45# steel with finish turning |

| Roller material | 45# Forging Steel with Chromium Plate |

| Chromium plate thickness | 0.05mm |

| Motor power | 5.5 kw |

| Roll forming speed | 15m/min (Adjusted with frequency changer) |

| Voltage | 3phase/380V/50Hz(Can be customized according to customer requirements) |

| Hydraulic pump station | 5.5kw |

| Cutting blade material | Cr12 with quenched treatment 58°C-62°C. |

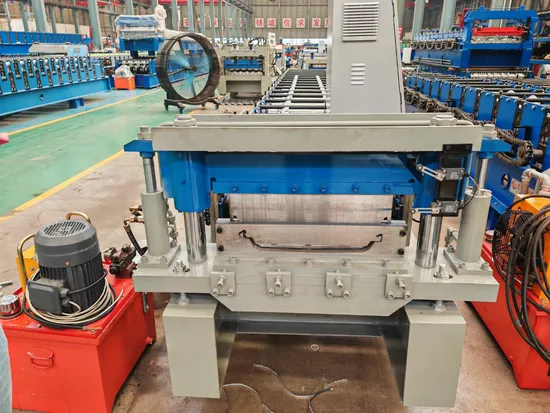

Detailed Photos

Among building materials, JCH 470 color steel tiles are a common type of roof tile. It is made of color coated steel plate, which is cold-formed into various wave shaped profiled plates by rolling, and has the characteristic of vertical locking seams. This type of tile is currently one of the most commonly used and popular roof tile types internationally.

Cutting system

Hydraulic punching and shearing, no burrs or deformation.

Roll forming rollers

High-precision rolled shaft, roll forming, selected high-quality steel, fast forming speed, safe and efficient, zero waste.

Feeding platform

The hand wheel can adjust the material opening, and the width can be adjusted easily, and the roller plate prevents scratches.

Hydraulic system

The equipment is well processed and operates stably.3 kilowatt pump station hydraulic station pressure is 10-12mpa 46# hydraulic oil.

Automatic Control System

Adopting programmable PLC control system and frequency converter speed regulation, the operation is simple and easy to use

Practical application

Certifications

Company Profile

FAQ

Q1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

>> High Quality 3pin XLR Cable One Female to Dual Male Y-Splitter Cables

>> Servo System Energy Saving Automatic Beverage Drink Plastic Sport Cap Making Gallon Prefrom Bottle Preform Injection Mold Machine

>> Smart Electronic Energy Meter: Single & Three Phase, Lorawan / WiFi / 4G / RS485 with Prepaid Electricity Remote Control and Ami / AMR Solution

>> SFI 16.1 Certified 5 Point Racing Car Shoulder Pad Safety Harness Seat Belt

>> Multi-Functional Sawdust Hammer Mill Made in China with CE Certificate

>> Stationary Concrete Mixing Plant 75m3 Concrete Batching Plant Superior Concrete Batching and Mixing Plant

>> Lifting Magnet for Steel Ball MW5

>> Servo Motor 20L Energy Saving Blow Moulding Machine

>> Factory Wholesale Cheapest Super Bright 200W H4 Car LED Auto Headlight Bulb

>> China Supplier Disposable custom printed food brown kraft paper box packaging

>> Xa7150, Bed-Type Milling Machine, , Meehanite Cast-Iron Construction,

>> Versatile Paper Shredder with Convenient Waste Bin for Cleanup

>> aluminium sliding window grill with frame aluminium sliding window with grill inside aluminum alloy windows with security bars

>> Hot Selling 8FT Outdoor UV Proof and Acid Rain Proof Children Trampoline for for Parks, Kindergartens, and Households

>> Hot Sale Continue Ultrasonic Plastic Welding Machine for PVC Pipes

>> 3 Phases Industrial Online UPS System with Isolation Transformer UPS

>> Custom manufacturer large helical spiral compression coil spring heat resistant heavy duty coil compression spring

>> Professional Manufacturer of 100% Waterproof Flooring Vinyl/Spc/PVC/Lvt/Laminate Flooring Planks Eir Surface 100% Virgin, Non-Slip, with EVA/IXPE Underlay

>> Taijia ZD410 Concrete Thickness measurement/NDT for Concrete floor slab thickness gauge

>> Chaozhou Modern Customized Ceramic Bathroom Wash Basin Canton Fair Sanitary Ware Counter Top Rectangular Sink

>> Wholesale Customized Semi Servo Disposable Under Pads Making Machine

>> Textile Machinery Drying Machine for Open Fabrics and Tubular Fabrics

>> Dimmer Time Area Control Smart Poultry Lighting Control System for Chicken Farm

>> Rare Earth Neodymium Metal Pellet ND Granules Evaporation Material CAS 7440-00-8

>> Energy-Efficient LED Spotlight, 5-Year Warranty, 24° and 36° Beam

>> Hot Sale DJ Stage Lighting Control DMX 192 Channels Dimming Console

>> Fully automatic small scale potato chips manufacturing making machinery price

>> Hurricane Impact Aluminum Jalousie Hinged Louver Window And Doors

>> China Brand Lingmei 90 Bwf Approved Quality Badminton Shuttlecock for International Play

>> P10SE-130742 Direct drive,car seats sofa leather compound feed digital sewing machine