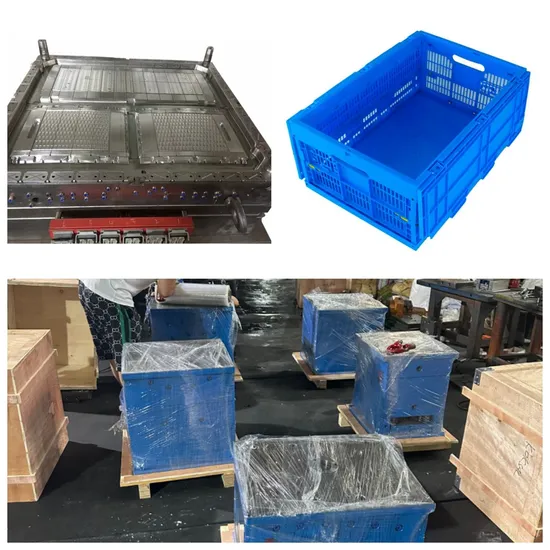

Plastic Injection Fruit Beer Crate Mould Wholesale Highly Stackable and Nestable Transport Box

Basic Info.

Model NO.

MELEE MOULD-67

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

PE

Process Combination Type

Single-Process Mode

Application

Commodity

Runner

Cold Runner

Design Software

UG

Installation

Manual Installation

Standard

HASCO

Customized

Customized

After-sales Service

Always

Size

as Your Request

Mould Life

800k Shots

Mould Material

P20, 718, H13...

Tooling Time

20days

Transport Package

Wooden Case

Specification

SGS

Trademark

OEM

Origin

Huangyan, Taizhou

HS Code

8480710090

Production Capacity

350sets /Year

Packaging & Delivery

Package Size

150.00cm * 100.00cm * 100.00cm

Package Gross Weight

5000.000kg

Product Description

FAQDetail description of Plastic Mould/mold.

Product Name: Plastic Moulds/molds

Product material: PP, or as per customer requirement.

Plastic Mould/mold cavity: As per customer requirement

Plastic Mould/mold size: Depends on your design.

Plastic Mould/mold material: P20, 718...

Plastic Mould/mold life: 800k shots

Plastic Mould/mold Runner system: Cold runner or hor runner

Plastic Mould/mold features: Good quality

Injection cycle time: 60seconds

Tooling time: 20days

MELEE MOULD Co., Ltd service process for Plastic Moulds/molds

1. Design/sample: Product, mould, etc.

2. Discussion: Mould material, cavity number, price, runner, payment, etc.

3. Order placed: According drawing or your samples.

4. Design mould: We will send mould design to customer for confirmation

5. Mould tooling: We start to make mould after mould design confirmed

6. Mould processing: Send pictures to customer every week for the customer to know the mould processing.

7. Mould shot trial: Send mould shot trial samples to customer to confirm mould quality

8. Delivery: Ship mould after mould quality confirmed.

| Product Name | Plastic Moulds/molds |

| Size | 800x450x500mm |

| Product description | as per customer requirment |

| Crate Mould/Mold cavity | 1cavity |

| Crate Mould/Mold size | 1050x750x700mm |

| Suitable machine | Around 650T |

| Crate Mould/Mold material | P20, 718 |

| Crate Mould/Mold life | 800k shots |

| Crate Mould/Mold runner system | Cold runner or Hot Runner |

| Ejection system | Ejector BAR |

| Crate Mould/Mold features | Good quality |

| Injection cycle time | 60 seconds |

| Tooling time | 20days |

>> Paper Bowl Forming Machine Made in China

>> 8" 10.1" 12.1" Inch Embedded PC I7 I5 J1900 Win 10 Touchscreen Barebone Industrial Panel PC

>> Polyester Four Layers Safety Factor 7: 1 Flat Webbing Sling

>> Advanced Truck-Mounted Aerial Lift for Construction and Maintenance

>> 1000kg Garden Micro Farm Hydraulic Mini 1 Ton Electric Excavator

>> Ntc Rtd Air Temperature Sensor Duct Mounted HVAC Temperature Sensor for HVAC System Temperature Sensor Channel

>> Custom Reflective Road Safety Short Sleeve Breathable Workwear Plain T Shirt Wholesale Work T Shirts Unisex

>> Gold machine mining processing plant mobile gold trommel wash equipment

>> Wiring Male and Female, Solid Copper Pins, 2.7 Socket Pins, Surface Gold-Plated Center Pin

>> Chinese Hebal Tea Hibiscus Sabdariffa Dried Roselle Tea in Bulk

>> High Efficiency Compact Battery Raw Materials Mixing Machine Vacuum Mixer for Lithium Battery Experiment Research

>> 15.6 Inch Lightweight Zipper Notebook Organizer Laptop Sleeve Shockproof Custom Logo Laptop Bag

>> Hydraulic Press Machine 80t 100t 150t 200t Vertical Tyre Tire Baler Machine

>> Vacuum Cleaner 12V 90w 3500pa Cordless High Suction Wireless Usb Portable Handheld Cleaner

>> Heavy-Duty Portable Concrete Mixer for Professional Construction Projects

>> 120cm Commercial Kitchen Restaurant Stainless Steel Upright Fresh Meat Refrigerator Freezer

>> 304 Stainless Steel Bone Saw Machine Sjc300-3A

>> MAICTOP car lighting system front lamp FOR ES ES350 2007 3 lens restyle headlight head light

>> Aluminum Bubble Level Inclinometer for Vehicles and Construction Mechines

>> Automotive Parts Brand New Aftermarket X5 E70 Rear Bumper Trim Panel 51127178280

>> 2.4G 5G 5.8G Antenna SMA Male Connector

>> 20 Mil Wearlayer Click System Spc Flooring Discontinued Click Vinyl PVC Floor Waterproof Indoor Wooden Vinyl Flooring Tiles

>> Stainless steel metal mesh disk / etched filter disc for coffee maker

>> Waterproof Motorized Folding Awning For Outdoor

>> Factory Wholesale Menthol Candy with Eucalyptus Flavor

>> Manufacturer custom size BBQ grills barbecue wire mesh grill grates outdoor cooking mesh

>> 6.3" Original for Oppo Realme 3 PRO Rmx1851 LCD Display Touch Panel Screen Digitizer Assembly for Realme 3 PRO 3PRO LCD Screen

>> Wide applied low price alluvial gold trommel screen for gold wash plant

>> Wholesales Promotional 5 Panel Blank Mesh Baseball Cap Embroidery Sublimation Print Custom Logo Advertising Trucker Hat

>> Heavy Duty & High Efficiency Glue Machinery of Plywood Machinery Woodworking Machinery