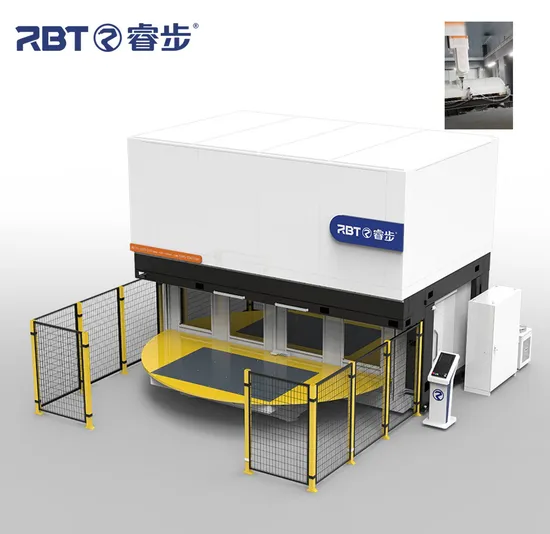

5 Axis CNC Machining Center with Rotary Twin Table for Composite Parts

| US$50,000.00-190,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

RB-F5-3323-Z10

Application

5 Axis CNC Working

Process Usage

CNC Non-Conventional Machine Tools

Movement Method

Contour Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Condition

New

X Axis Effective Stroke

1900mm

Y Axis Effective Stroke

3000mm

Z Axis Effective Stroke

800mm

B-Axis Rotation Angle

+/- 130 Degree

C-Axis Rotation Angle

+/- 540 Degree

X/Y Axis Maximum Speed

50m/Min

Z Axis Maximum Speed

20m/Min

Repeat Accuracy

+/-0.05mm

Voltage

380V

Total Power

9.9-29.1kw

Spindle Power

3-20kw (Customizable)

Frequency

50Hz

Weight

19.5t

Application & Function

Thick Plastic & Composite Materials Processing

OEM

Machine Can Be Customized as Required

Transport Package

Export Safety Packing (Customized Packing)

Specification

L5100*W2610*H3982mm

Trademark

RBT

Origin

Quanzhou, China

HS Code

84659990

Production Capacity

200set/Month

Packaging & Delivery

Package Size

510.00cm * 260.00cm * 400.00cm

Package Gross Weight

19500.000kg

Product Description

Product Description5 Axis CNC Machining Center with Rotary Twin Table for Composite Parts

Product Parameters

Content | Parameter | Content | Parameter |

| Name | Non-metal Truss Type 5 axis CNC Machine | Brand | RBT |

| Model | RB-F5-3323-Z10 | Voltage | 380V |

| X/Y/Z Travel | 3300*2300*1000mm | Power | 25.35 KW |

| C/B Axis Travel | +/- 540° / +/- 120° | Spindle power | 17KW |

| Control system | Taiwan SYNTEC | Weight | 19500KG |

| Origin | Guangdong/Fujian | Warranty | 1 Year |

Detailed Photos

1. Structure consists of: X-axis (double drive), Y-axis, Z-axis, C-axis, B-axis, working spindle, rotary table, dust-proof and sound-proof top cover .

2. Movable worktable (does not participate in the five-axis linkage processing movement, and automatically exits the machine processing position after the product is processed), making loading and unloading safer and more convenient, and realizing automatic interaction between the processing area and the loading and unloading area.

3.The system adopts SYNTEC five-axis linkage CNC system. The machine combines power, speed and precision and can be equipped with multiple functions such as dust collection, automatic tool change and RTCP. It can cut difficult-to-process materials in the shortest time to obtain very high-precision contours and profiles.

4.Italy Hiteco double swing head spindle, can achieve 360° swing Angle, fast speed, high precision.

5. 8 station tool library design, up to 8 different specifications of tools can be automatically replaced, which can meet more processing needs.

6.We provide complete and feasible dust collection solutions based on the customer's factory layout. The machine has a reserved dust collection port, which allows for easy installation of a dust collection device.

Machine Application

RBT 5 Axis CNC Machine is Widely used in Mold manufacturing, composite material processing, and thick sheet thermoforming processing in industries such as aerospace, rail transit, automotive interior and exterior, sporting goods, medical beauty, white goods, handicrafts, and sanitary ware.

Applicable processing materials:

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, carbon/carbon, glass fiber reinforced plastic, aramid fiber honeycomb, aluminum honeycomb, honecomb sandwich panel, styrofoam foam, EPS, wood, MDF, plaster, resin, ect.

Thermoformed plastics: ABS, PVC, PC, PP, PS, PE, PET, HDPE, PETG, Acrylic etc.;

Soft metal : aluminum/copper/ zinc, aluminum mold.

Certifications

CE Approved five axis cnc machine

All our equipment must undergo rigorous testing and quality control before shipment, and use laser interferometers to ensure accuracy.

Company Profile

Packaging & Shipping

1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2.Shipping : Container transport.

Main Market

>> Hotsale Universal Auto 5 Series E60 Engine Hood For BMW E60 Body Kit

>> Canvas Bags Waterproof School Outdoor Hiking Unisex Laptop School Backpack Bag

>> Chinese Taiji Racket Set with Great Quality Sports Racket for The Aged

>> Flanged taper SAE841 bronze brass bushing

>> Premium Fluted Acrylic Soaking Bathtub in Glossy White Finish

>> Automatic Concrete Slab Cutting Machine

>> Composite Motor & Driver for Packaging Equipment

>> Cast Iron High Alloy Yankee Cylinder

>> Automatic Hot Plastic Elastic Belt Cutting Machine Hx-360b

>> Vmc855 Vmc850 Three Axis 4th Axis CNC Turning Center CNC Milling Machine

>> Customized Autoclave Indicator Strip for Chemical Testing in Surgery

>> Supply Hot sale Amazon Egg Waffle Pan Non-stick

>> Heavy Glass Crystal Designer Perfumes with Long-Lasting Scent

>> Factory Audit /Inspection Service/Third Party Inspection Service

>> New Hydraulic Agriculture Machine Aquatic Weed Harvester Machine Good Price Water Hyacinth Harvester

>> Big Diameter Single Drum Carbon and Allotype Steel Inverted Vertical Wire Drawing Machine

>> Heavy-Duty Large Plastic Shredder for Manufacturing Waste Recycling

>> New High Efficacy Wholesale Lm301b 1000W Waterproof LED Grow Lights

>> OEM Service 15/18/20 stages Ionic Charcoal Kdf Filter Cartridge Shower Filter Cartridge For Bathroom

>> 2018 10 atm sports military quartz watch time zone watch for man

>> Customizable Air Conditioner Plastic Tangential Fan Impeller Ultrasonic Welding Machines for Split Plastic Cross Flow Fan Blade

>> 2 Deck 2trays Commercial Gas Oven Baking Machine Et-Rfl-22c

>> Wooden Hangers Wooden Products Fast Drying Equipment Microwave Dryer

>> All stainless steel nursing cart medical equipment emergency trolley

>> ISO 287 Digital Precision Moisture Meter For Plastic & Rubber

>> X2012 Double Column Single Milling Head Plano CNC Milling Machine

>> Saintshine 250kVA 300kVA 350kVA 400kVA 500va 600kVA 800kVA 1000kVA CE ISO Certified Diesel Generator with Silent Canopy Factory Industry Use

>> Football Jerseys Custom Men Soccer Jerseys Set Football Shirts Boys Soccer Uniforms Soccer Wear

>> Trunk Lid Tailgate Lift Control Module for bmw F02 F18 F25 F26 F07 61357394649

>> surgical POLYPROPYLENE sutures