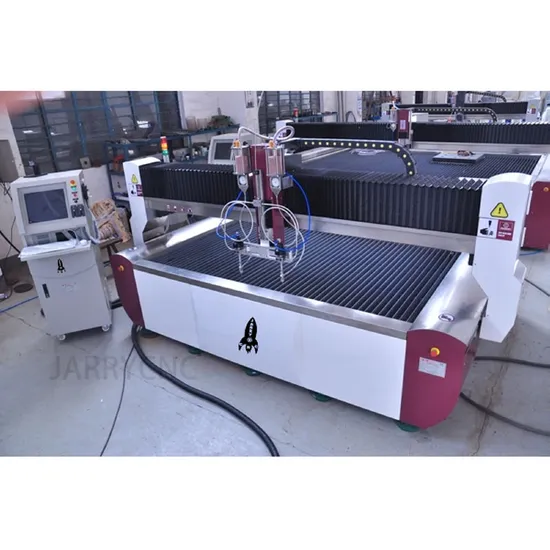

Factory Hot Sale Wj-3015 Automatic Waterjet Cutting Machine

| US$9,860.00 | 1 Piece (MOQ) |

Basic Info.

Control

Manual

Application

Metal, Ceramic, Glass

Power Source

Electric

Style

Electro-Hydraulic

Maximum Output Flow

3.7L/Min

Maximum Orifice

0.33mm

Max Output Pressure

420MPa

Intensifier Configuration

Single

Pressure Control

Manual

Shifting Control

Electro-Hydraulic Control

Motor Power

37kw/50HP

Voltage

380V/50Hz

Width

1300mm

Length

1800mm

Height

1500mm

Operating Weight

1200kg

Transport Package

Wooden Pallet with Plastic Film

Specification

Depending on the model

Trademark

JARRYCNC

Origin

Anhui

Production Capacity

500 Set/Sets Per Month

Product Description

Product ParametersCutting table Main technical parameters

| Model | YCG-3742S |

| General data | |

| Maximum output flow | 3.7L/min |

| Maximum orifice | 0.33mm |

| Max output pressure | 420mpa |

| Intensifier configuration | Single |

| Pressure control | Manual |

| Shifting control | electro-hydraulic control |

| Pump power | |

| Motor Power | 37kw/50HP |

| Voltage | 380V/50Hz |

| Physical data | |

| Width | 1300mm |

| Length | 1800mm |

| Height | 1500mm |

| Operating weight | 1200kg |

| Options | Air cooling/Water chiller |

| Model | YCG-3742S |

| General data | |

| Maximum output flow | 3.7L/min |

| Maximum orifice | 0.33mm |

| Max output pressure | 420mpa |

| Intensifier configuration | Single |

| Pressure control | Manual |

| Shifting control | electro-hydraulic control |

| Pump power | |

| Motor Power | 37kw/50HP |

| Voltage | 380V/50Hz |

| Physical data | |

| Width | 1300mm |

| Length | 1800mm |

| Height | 1500mm |

| Operating weight | 1200kg |

| Options | Air cooling/Water chiller |

| No. | Name | Amount |

| Spare parts for the machine | ||

| 1 | Ruby | 4 |

| 2 | Nozzle | 1 |

| 3 | Connecter of pipe(each one for larger and samller) | 2 |

| 4 | The shift valve elements | 1 |

| 5 | The air valve repair kit | 1 |

| 6 | Shield cap | 2 |

| 7 | Hp water switch kit | 1 |

| 8 | Hp seal(without copper cake ) | 1 |

| 9 | Low pressure oil seal | 1 |

| 10 | Lp check valve repair kit | 1 |

| 11 | filter element(5Micron) | 1 |

| 12 | filter element(1Micron) | 1 |

| 13 | Fold filter(0.45Micron) | 1 |

| 14 | The Blue Lubricant | 1 |

| 15 | O ring and assembled ferrule | 1 |

| Special tools for machine | ||

| 1 | 60K Intensifier Tool kit (For H-P Seal) | 1 |

| 2 | Wrench Girth (For H-P Cylinder) | 1 |

| 3 | Wrench,Spanner(For End Cap) | 1 |

| 4 | Wrench,Spanner(For HIGH PRESSURE SWITCH) | 1 |

1. CUTTING TABLE

1.1 Platform Body

1.1.1structure feature

- The machine body with the welding box structure, then make stress relief by annealing process.

- Table body and water tank which are split structure, lessen the splash of sands and water into moving parts,It is also conducive to the disassembly and transportation of the machine.

- X-axis and Y-axis transmit to rolling ball screw mandrel.

1.1.2Controlling system

We adopt Mitsubishi digit servo system(Bus communication protocol).

1.1.4 Chief parameter for drilling

- No-load speed : 1750 rpm;

- Maximum drilling capacity: diameter 8mm (aluminum alloy);

- Total stroke: 100mm

-Working stroke: 50mm

-Propelling force at 6 kg air pressure: 100 kg

-Power: 450watt

-Compressed air consumption: 650L/min

-The smallest trachea: diameter 10mm

-Tool clamping range: diameter 0~10mm

1.1.5 Transmission system

- We adopt HIWIN linear guide rail and TBI ball screw to ensure accuracy and quality.

1.1.6 Prevention system

- Over travel auto spacing function and soft spacing function

- Unique prevention design: new mazy protection and z-axis totally enclosed professional design prevent sand and water from eroding the guide screw and linear guide rail.

1.1.7 Lubrication system

- We adopt auto mass lubrication system to make oil reach every oil site on time and also make table steadier and easier.

| More Pictures |

Product Applications

More Products

| If you want to know more product details, please feel free to contact us! |

| CNC bench plasma cutting machine | Bench laser cutting machine | CNC EDM wire cutting machine |

| CNC Vertical Machining Center | Flat Bed CNC Lathe | Slant bed CNC lathe |

| Universal Engine Lathe | Heavy Duty Engine Lathe | bench lathe |

Chizhou Jarry CNC Machinery Co., Ltd was established in July 2014.

We supply CNC-Lathe; CNC-Milling Machine; CNC Cutting Machine, CNC Spare Parts, CNC Accessories. We also supply other machinery for our clients all over the world. Annual sales is over ten million USD. Our machines has been exporting to Europe, Asia, Africa, South America, North AmericaAustralia and others, realiable after-selling serviceOur company has established perfect hassle-free service system in quick response, which covers pre-sales, sales and post-sales to providespecialized and standardized services in quick response for the customers and safeguard the rights and interestes of the customers.

Our company offers variety of CNC Machining Center, CNC Lathe and other machine tools which can meet your multifarious demands. We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

Certifications

Packaging & Shipping

FAQ

1. What is the payment Terms ?

A : T/T or L/C ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2. what is your company mainly produces ?

A : Our company is a professional machine tool manufacturer with many years of experience. The company mainly produces CNC-Lathe; CNC-Milling Machine; CNC Cutting Machine, CNC Spare Parts, CNC Accessories, etc...

3.When is the delivery time?

A: If the machine you will order is standard machine, we can ready the machine within 15days. if some special machines will be some longer. The ship time is about 30 days to Europe, America. If you are from Australia, or Asia, it will be shorter. You can place order according to delivery time and ship time.we will give you the answer accordingly.

4. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

5. What is the packaging of the machine?

A: The standard packaging of the machine is wooden pallet with plastic film.

Contact Us<<

>> Industrial-Grade Hb Series Gearbox Reducer for Enhanced Performance

>> Japan Isuzu Ftr Fvr Truck Mounted Folded Crane Truck

>> Wholesale multifunctional kitchen bamboo bulk natural wood fiber round bread pizza chopping cutting board with handle set

>> Automatic Feed Horizontal Milling Machine X6036 Lifting Table Vertical Milling Head Can Be Added

>> Taijia river channel doppler flow meter ultrasonic handheld ultrasonic flow meter

>> HC-L041A Cheap price Optical Dental electrical handpiece kits 2/4 holes Dental high speed Handpiece Set

>> China Manufacturer Price High Quality Autoatmic Industrial Bakery Soft Biscuit/Cookie/Cracker Snack Making Machine

>> Good Corrosion Resistance High-Pressure Equipment Single-Arm Low-Temperature Marine Loading and Unloading Arm Machine with Swivel Joint

>> Double hung vinyl windows upvc windows single hung window

>> Hot Selling Baby Product Nappy/Nappies/Baby Diapers/Baby Care for Belarus

>> Industrial-Grade Plastic Crate Injection Molding Machine for Warehousing

>> Small Capacity Food Storage Container with Bamboo Lid High Storage Jar Candle Candy Cookie Jar with Wooden Lid Glass Bottle for Sale

>> Digital Addressable Ws2812 144LEDs 43.2W DC5V Full Color LED Pixel Strip

>> Bullmer D8002 Cutter Spare Parts 053759 Tooth Belt 16t5 X 815

>> New Compatible Color Toner for Xerox Docucolor 550/560/570/5580/6680/7780

>> 2020 High Technology Ceramic Homogenizer

>> Custom Design Eco Friendly Reusable Promotional Shopping Tote Bags Foil Gold Non-Woven Bag

>> Metal Melamine Office Small Table

>> China Precision Cylindrical Grinding Grinder Machine M1022 Hydraulic Surface Grinding

>> 2 Wheel Cheap New 500W/800W 48V/60V Optional E- Scooter Electric Bicycle Electric Scooter Electric Motorcycle Sale

>> valve tool repair shop tool copper tire valve extension

>> Food Grade Inline Liquid Xanthan Gum Powder Mayonnaise Mayonnaise Mixer

>> 10 Inch Model 15 Model 16 Gen1 Free Float Quad Rail Handguard with Barrel Nut

>> Hot Selling Full Automatic Paper Cup Machine

>> Fashion Attractive Design Handicraft Card Package Paper Box

>> Android 10.0 Full Touch IPS Screen 10.25 Inch with DSP Carplay Bt Amplifier Car Video Car DVD Player Radio

>> Used Doosan Toyota Caterpillar Sany Excavator Brand New Hyundai 2.5tons 3tons 4tons 5tons Mini Excavator Hydraulic Crawler/Wheeled 320d Cummins Engine Excavator

>> Custom Boxing Ufc MMA and Octagonal Boxing Cage for Competition and Training

>> Newest Black Bitumen Paint Hall Anchor

>> Digital Marshall Stability Tester Bitumen and Asphalt Testing