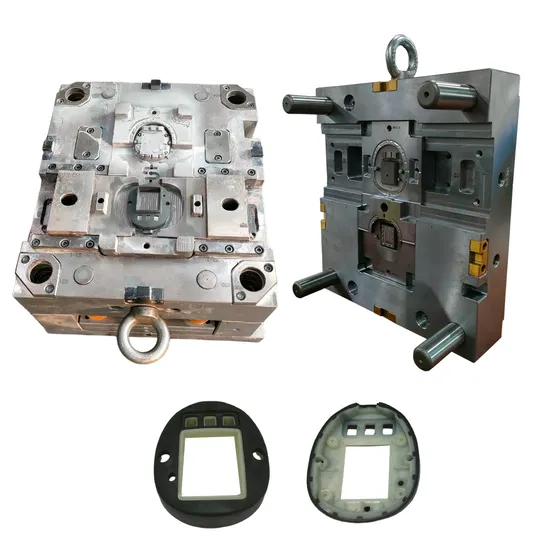

OEM ODM Double Color Injection Mould for Plastic Cases

| US$2,000.00-10,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HW1454

Mould Cavity

Single Cavity

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Furniture, Electronic, Hardware

Runner

Cold Runner

Design Software

Pro-E

Installation

Fixed

Certification

ISO

Standard

DME

Customized

Customized

After-sales Service

Any Question Please Feel Free to Contact Us.

Name

Double Colours Plastic Injection Mold

Mould Material

S136,Nak80,Etcs316,P20,718h,2378,Nak80,etc

Mold Cavity

Single Cavity / Family Molds / Multi Cavity

Mold Life Time

300K~1000K Shots

Surface Treatment

Textured,Glossy or Mirror Polished,Printing,Planti

Molding Material

PP,PPA,PC,ABS,HDPE,POM...etc

Lead Time to T1 Sample

4~5 Weeks

Lead-Time for Production

1~2 Weeks

Transport Package

Wooden Cases/Air/Sea

Specification

Custom

Trademark

HOWE or Custom

Origin

China

HS Code

84807100

Production Capacity

50sets/Month

Packaging & Delivery

Package Size

51.00cm * 50.00cm * 56.00cm

Package Gross Weight

720.000kg

Product Description

Discover our exceptional and customizable 2K injection mold and overmolding solutions, ideal for crafting intricate and durable plastic components tailored to your specific needs. Product Description| Product Name | OEM custom injection mould for plastic part |

| Mold Base: | LKM,HASCO,DME,etc... |

| Product Name: | UL Approved mold maker plastic injection molding Mould overmoulding |

| Mold Cavity: | Single, Mult, Family... |

| Molding Material: | ABS, PA6, PA12,PA66, PBT, PC,PC/ABS,PC/PBT,PE-HD,PE-LD,PEI,PET,PETG,PMMA,POM,PP,PPE,PS,PVC,SA... |

| Color: | transparent, solid color according to your requests |

| Surface: | textured,glossy or mirror polished,printing,plantingect. |

| Design software: | PRO/E.Solidwork,UG.Moldflow.Autocad,etc |

| Mold Material: | S45C, P20, 718, 718H, 2738, 738H, NAK80, SKD61, E420, etc. (for reference only),Autodesk Inventor, SolidWorks, CATIA V5, Solid Edge, UGS NX, Pro/ENGINEER |

| File Formats | STEP, IGES, SAT, DWG, DXF, VDA. |

| Mold Life: | 300,000~1,000,000cyces according to your requests |

| Runner: | Cold, hot runner such as YUDO.MASTER.SYNVENTIVE.etc. |

| Lead time to T1 sample: | 3~5 weeks |

| lead-time for production: | 1~2 weeks |

| Quality: | ISO 9001:2015 |

| Precision: | 0.005mm |

| Service: | OEM &ODM service. and mold for exports as well. |

Company Profile

Founded in 2010, Dongguan Howe Precision Mold Co., LTD has emerged as a leader in innovation, proudly holding an ISO 9001:2015 certification. Our state-of-the-art facility in Changan town, Dongguan City, China, employs a team of over 40 skilled professionals. We deliver advanced manufacturing capabilities that significantly enhance efficiency, meeting and exceeding customer expectations in the injection mold and molding industry.

Leveraging years of expertise, HOWE excels as a top-tier injection mold maker, adept at fulfilling the stringent demands of manufacturing molds and products for Automotive, Household appliances, Office appliances, Commodities, Telecommunications tools, and Medical apparatus. Our high-quality molds and products are predominantly exported to major markets including the USA, Europe, India, and Mexico.

At HOWE Mold, we commence with premium materials that align with rigorous industry standards for impeccable quality assurance. Committed to excellence, our dedicated team ensures top-tier parts, services, and technical support, guaranteeing customer satisfaction and industry compliance. Offering 24/7 accessibility, we connect with customers through toll-free numbers, fax, email, Skype, and our web platform. Expanding our footprint in the international automotive sector, we foster strategic partnerships to deliver unparalleled service and achieve your project objectives.

Work Shop

Mould Trade Process

Quality Control

Certifications

Tooling Weekly Report

FAQ

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q. I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q. My products have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q. Can I test my idea/product before committing to mould tool manufacture?

A. Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations

Q. What shall we do if we do not have drawings?

A. Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

>> Hrdraulic Press Brake CNC Bending Machine Pbh-63ton/3200mm

>> New Design 100% Rayon Dyed Fabric for Dresses Garment

>> High Speed Joint Leveling Machine

>> PE Series Jaw Crusher Equipment for Crushing Ores

>> Dream Diamond Lab Grown Hpht Diamond Cutting Machine

>> High Quality Billiard Table with 9FT Pool Table Size

>> Compost Turner Machine

>> Summer Joggerwholewholesale Custom Sports Muscle Bodybuilding Dry Fit Plain Tank Tops Gym Running Singlets Stringer

>> Multipurpose Oscillating Machine with CE for Wood Acrylic Foam Cardboard

>> Chinese Agriculture Rice Combine Harvester 688q Mini Rice Combine Harvester Paddy Beans Harvester Kubota Used 90% New Machinery

>> Hot Sale Luqing Brand 1.8 Ton Mini Small Wheel Loader with CE for Euro

>> Mirror Small Glass Unit for Iveco Daily 2006-2011 L 3801928 R 3801929

>> Auto Spare Parts Universal Flat Frameless Car Windshield Wiper Blades Universal Car

>> High Speed Decorative Base Paper Machine

>> Fully Hydraulic Crawler Mini Excavator with EPA Engine Hydraulic Operator Lever

>> Most Professional Reliable Yiwu Guangzhou Dropshipping Buying Commission Agent in China

>> MOV-01 2 position 3 way 1/8" hand turn switch Pneumatic Selector Mechanical Valve

>> High Output Manufacturing Pet Dry Dog Food Production Line Extruder Floating Fish Feed Pellet Making Processing Machine

>> 15 Years Factory Experience Yiwu Chemical Lace Fabric

>> Advanced Tube Conveyor System for Streamlined Material Handling

>> Compatible with Select IC Corporation Pedals for Car Electric Throttle Pedal

>> Coiler Machine Coiling Machine CNC Machinery Part Polishing

>> LED Light Truck Tail Light with E-MARK/Adr Lt111

>> Memory Foam Seat Cushion for Tailbone Pain Office Chair

>> 7 in 1 Body Positioner Bed Wedge Memory Foam Pillow for Sleeping

>> Telescopic Electrical 12V 130W Olive Harvester Picking Machine

>> Customized PP PE Film Recycling Granulating Line Waste Plastic Pelletizing Machine

>> High Efficiency in Knotting in Warp Beams Knotting Machine

>> Customized Buy Cheap Powerful Green 532nm 5MW~50MW Laser Line Laser Module

>> up-128t High Pressure Injection Molding Machine with 200L Tank Volume