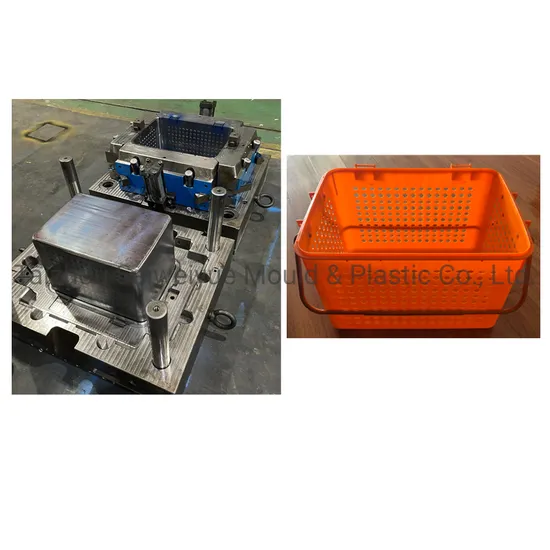

Polypropylene Basket Moulding Kitchen Utensils Plastic Container Box Mold Baskets Injection Mould

| US$8,500.00-10,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

SWY0824

Surface Finish Process

Mirror Polishing

Mould Cavity

Single Cavity

Plastic Material

PP

Process Combination Type

Compound Die

Application

Home Use

Runner

Cold Runner

Design Software

UG

Installation

Fixed

Standard

HASCO

Customized

Customized

After-sales Service

Lifelong

Mould Steel

P20h

Mould Base

45#

Mould Size

910*760*576mm

Mould Weight

2675kg

Cycle Time

Around 60s

Injection Molding Machine

4000g/800t

Demoulding Method

Using Robot Hand to Pick

Lead Time

55 Days

Transport Package

Wooden Box

Specification

440*310*305mm

Trademark

SWY MOULD

Origin

Taizhou Huangyan

HS Code

8480719090

Production Capacity

500 Sets/Year

Packaging & Delivery

Package Size

91.00cm * 76.00cm * 57.00cm

Package Gross Weight

2675.000kg

Product Description

Mould NamePolypropylene Basket Moulding Kitchen Utensils Plastic Container Box Mold Baskets Injection Mould

Mould Specifications

| Part Resin | PP |

| Part Size | 440*310*305mm |

| Mould Steel | P20H |

| Injection System | Cold runner |

| Mould Cavity | 1 |

| Mould Size | 910*760*576mm |

| Mould Weight | 2675KG |

| Cycle Time | Around 60 seconds |

| Injection Moulding Machine | 4000g/800T |

| Demoulding Method | Using Robot Hand to pick |

| Lead Time | 55 days |

| Moulding Suggestion | 1. After the mould opening distance reaches 220mm, then ejecting the oil cylinder to stick the product on the mould core side, and at last use a robot/hand to pick products. 2. Pay attention: During the first few producing, must not make full products, like the picture shows, producing around 6-8 products then setting parameters to make full products little by little, otherwise will make mould swell. |

Product &. Mould Design What is a good mould? It must have good quality to meet production requests stable and smoothly, and no need to spend too much time & cost on maintenance and repair.

A good mould design is a critical start. SWY MOULD has 6 designers in total with more than 10 years of experience, they always pay special attention to customers' specifications and details by thinking about the cost-saving solution based on stable and good quality. Their years of experience in exporting moulds gives them great knowledge of global mould standards and quality demands.

Software related:

Mould Flow: Mould Flow Analysis

3D Modeling: Pro/Engineer, Unigraphics, Solidworks

2D Drawing: Auto-CAD, E-drawing

The following international data format works OK for us:

2D drawing files: dwg, dxf, edrw

3D drawing files: step, Igs, X-T, prt, sldprt

Final Product &. Mould

Mould oil cylinder operation suggestions

Shipment of plastic injection mould in SWY

1. After we get our customer's confirmation for shipment, we attach a plate to the mould: this shows the product's serial number, production year, and mould information.

2. At this stage we paint the mould with anti-rust oil, and then we wrap it safely in a plastic bubble bag for protection.

3. We nail the package as necessary to ensure that mould reaches customers safely.

4. We put the package in a wooden case to protect it during shipping.

5. We nail the wooden case carefully and stick the marks to ensure that mould reaches customers safely and quickly.

6. For Any other points that need to pay attention to we will make a file and print it, and send it with mould together.

About Our Taizhou Saiweiyue Mould & Plastic Co., Ltd

1. Specialized in plastic injection moulds

Taizhou Saiweiyue Mould & Plastic Co., Ltd. is specialized in manufacturing injection moulds and plastic products, which is located in Huangyan District, Taizhou City, the China mould town. All of the moulds are designed by our professional technicians using UG, Pro/E software, and a whole set of advanced and mature technology in CAD/CAE/CAM. We have mould technicians with working experience of more than 20 years, who have been making different kinds of moulds. Besides, we will act as an agent for you in producing plastic parts.

2. Equipped with full tooling machines

SWY Mould has advanced tooling equipment in order to make sure our mould quality and mould precision. We have 5-axis High-Speed CNC Milling Machines, Gantry High-Speed CNC Milling Machines, Large/middle/small Die Spotting Machines, CNC High-Speed Engraving Machines, Mirror Electric Spark(EDM), Precision Electric Spark(EDM), Slow-feeding Wire-cutters Machines, Medium-feeding Wire-cutters Machines, Precision Grinding Machine, Drilling Machine, etc. We hold the belief that high-precision tooling equipment can make sure mould quality. We not only provide technical support for our customers but also offer them a complete solution in the plastic injection moulding industry.

3. Having a nice environment in the workshop

With the principle of 5S(SEIRI, SEITON, SEISO, SETKETSU, SHITSUKE), our workshop environment is kept clean, and all the tools and parts must be put in order. Everything is under a perfect management system. We believe a good working environment can make working more efficient, ensure mould quality, and also fasten mould delivery at the same time.

4. Providing good quality moulds

We promise to offer you top-quality moulds with real-quality steel, strict heat treatment, and serious control. We focus on product and mould construction design and insist on making moulds durable and easy maintenance. For all of our moulds, we use international standard mould spare parts, to ensure complete moulds' accuracy and durability. At the same time, greatly shorten mould delivery and be convenient for mould maintenance and spare part change, such as JunFan cylinder from Taiwan, Japan Daido springs and Korea Samsol springs, Brevini hydraulic motor from Denmark, Misumi, Hasco, DME, etc.

We're sincere to invite your visit, communication and cooperation, and are looking forward to being your excellent mould supplier!

Feedback From SWY Customers

SWY MOULD Common FAQ For Our Customers

Q1: Are you a trading company or mould manufacturer?

A1: We are a mould manufacturer, we have our own mould factory located in Huangyan, Taizhou. We are making plastic injection moulds, also with mould mass production service.

Q2: How to go to your factory?

A2: From Shanghai-3 hours by train; from Guangzhou-2 hours by aeroplane; from Wenzhou-1 hour by train; from Ningbo-1 hour by train; from Hangzhou-2 hours by train; our factory to Luqiao airport is around 1 hour, and to Taizhou train station is around 20 minutes.You can send the information about the flight or train to us, we can arrange to pick you up. If needed, we can book a nice hotel at a reasonable price for you first. Welcome to contact us, and we will offer you the most thoughtful arrangements.

Q3: How long is your delivery time?

A3: Generally about 35-55 working days, we will fast as soon as possible under the premise of good quality mould.

Q4: How about your after-sale service?

A4: The mould warranty period is 3 years (without damage caused by human factors or accidents), later for mould-wearing spare parts we can help you purchase and send you.

Q5: I have an idea for a new product, but don't know if it can be manufactured, can you help?

A5: Yes, sure! We can design and make 3D printing samples for your assembly. After you confirm, we begin working, if necessary, we will provide a DFM report or Mold-flow analysis.

Q6: Can you help us ship the plastic mould?

A6: Yes, with honour. We have a long-term cooperate shipping company and give you the best price we can get. Also, you can ask your own shipping forwarders, we will help you deal with other documents. SWY MOULD has our own export and import rights, we are familiar with exporting plastic moulds to customers.If you need more plastic boxes & basket mould, please click here; for more information, please contact us.

What's a good mould-making company?

Here SWY MOULD would like to discuss with you how to find a good mould-making company in China.

Being a plastic injection mould maker today means more than just cutting steel.

A plastic mould maker should support his injection moulding customer from the beginning of a new part concept right through to mass production of the parts, especially when trying to reduce cycle times by using plastic injection moulds.

The mould maker should know what questions to ask and be on the lookout for part design issues that could make moulding and mould construction difficult. Changes made at the early stages could save the moulder thousands of dollars in waste in terms of rejects and slow cycle times. This means the customers can make more money, get the jobs completed sooner, and won't suffer the stress and headaches associated with poor decision-making that often happens at the start of a product development cycle.

The plastic mould maker should also be present during mould commissioning. Most often new moulds have not been tested in a production environment and they will usually have some minor issues that relate to mould manufacture. The mould maker needs to see the effect on production and discuss with the customer the best way to fix it. Another reason why a mould maker should be present during commissioning is to ensure water circuits are connected correctly. Water circuits must not be looped as this can cause part quality problems such as warpage. If customers can't come to our factory for mould testing, SWY MOULD will take videos and send machine setting parameters sheets to customers for reference. Later if there are any problems during customer mass production, SWY MOULD will instruct and give professional advice.

Process of making plastic injection mould in SWY MOULD:

Balance price with quality. Do your research and pay a bit more to get a mould that will produce quality plastic parts consistently. Low price is not the final pursuit, we need to consider better cost performance. So more details you need to discuss with mould company about your project. Welcome to contact Shine, we will let you know more about the plastic injection mould technology and the way to achieve better value for your money and time.

>> Aiotek Hydraulic Electric Press Brake 1lt40/2000 Steel Metal CNC Bending Press Brake Machine Servo Electric Press Brake

>> 16A 32A 63A 125A Waterproof Outdoor Industrial Plug and Socket with Factory Price

>> Pet Plastic Mini Cartoon Honey Bear Bottle Blow Making Molding Machine

>> Enamel Cast Iron Gas Hob Parts Gas Hob

>> Filing Cabinets with Charging Post, Locking Mobile Side File Cabinet for Home Office

>> Animal Poultry Feed Making Machine Floating and Sinking Fish Feed Production Line

>> Modern Floor Lamp Floor Lamp New Meta Vintage Floor Lamp

>> Bamboo Cutting Board Over The Sink With Collapsible Removable Strainer And Juice Groove

>> Professional Design Hot Sale Glass Laser Cutting and Splitting Machine for Glassworks

>> Custom Logo Crossbody Outdoors Sports Backpack Pickleball Padel Racket Bag Tennis Equipment Sling Bags for Women

>> Wholesale Army Military Pants Camouflage Outdoor Tactical Pants IX7 Men

>> KJ65 Surveillance System CCTV Camera Video HD Dome car Camera

>> Pet PVC PS Seedling Tray Nursery Flower Pot Plant Growth Tray Making Machine

>> Spunlace Nonwoven 55% Wood Pulp 45% Polyester Printer Cleaning SMT Stencil Wiper Paper Roll

>> Best Selling Products Steel Food Contact Electric Wire Barbecue Oven Rack

>> Fresh Straw Grass Cutter Machine for Horse Feed

>> Bottles Pipe Scrap Crushing Machine / Plastic Bag Crusher / Pallet Shredder

>> Hot Sale Water Park Fiberglass Water Slide Pool Slide for Kids

>> High Precision Grinding M1022 High Quality Metal Manual Machine for Sale

>> Multifunctional Aramid Yarn for Optical Cables with Precise Custom Specifications for Enhanced Fiber Transmission

>> ZICAR high quality wood woodworking 4 head spindle four side thickness planer moulder machine

>> Salvagnini Press Brake From Anhui Yawei with Ahyw Logo for Metal Sheet Bending

>> 400-700MHz 50W Anti Drone Module for Anti Drone Detector Anti Drone System

>> Plastic Recycle Machine Crusher for Plastic Boxes Bottles etc

>> BestScope BS-2020M Economic LED Education Student Outdoor Easy Use Biological Microscope

>> Module spare parts FBM224 P0926GG

>> Automatic hydraulic peanut oil press machine, manual oil press machine,small oil pressing machine

>> PC360 Excavator Rake Excavator Clamp Excavator Bucket Excavator Excavator

>> LED Light for Outdoor Environment/Outdoor Gantry Crane or Overhead Crane

>> Metal-Cutting CNC Tools Semi-Closed Loop Control Industrial Wire Cutting Machine