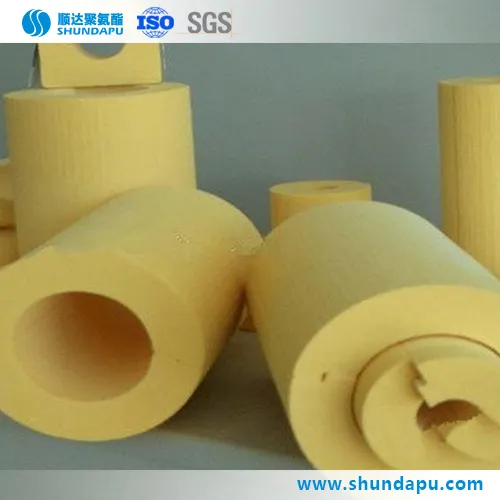

Polyurethane Foam Resin for Pipe Insulation System House White Component

| US$1,900.00-3,000.00 | 200 kg (MOQ) |

Basic Info.

Model NO.

SDB10D-Z01

EINECS

Polymer

Material

Polyurethanes/PU

Usage

Engineering Plastics

Plastic Properties After Heated

Thermosetting Plastic

Plastic Forming Method

Injection

Color

Yellow

Core Density

≥60 Kg/M3

Radial Compressive Strength

≥0.3MPa

Initial Thermal Conductivity(50°c)

≤0.033W/(M•K)

Close Cell Content

≥88%

Water Absorption

≤10%

Appearance

Pale Yellow Liquid.

Specific Gravity at 25°c

1.10±0.10 g/cm3

Viscosity at 25°c

300±100 Cps

Shelf Life

12 Months

Transport Package

Iron Drum

Specification

200kg

Trademark

shunda

Origin

China

HS Code

39072090

Production Capacity

100000tons

Product Description

DESCRIPTIONSDB10D is a kind of blend polyol used for pipe insulation system for city heating or cooling. When it combined with isocyanate(PM200) leads to the formation of rigid polyurethane foam by using PU injection foam equipment .The foam formed has the characteristics as following: The thermal conductivity is low, which can meets the requirements of city heating and energy saving. Service life of the foam is very long, over 30 years. High temperature resistance and good dimensional stability of the foam, the highest temperature range is 140 ºC. TYPICAL PHYSICAL PROPERTIES

| Physical Properities | Test Method | Metric | Value |

| Core Density | GB/T 6343-2009 | kg/m3 | ≥60 |

| Radial Compressive Strength | GB/T 8813-2008 | MPa | ≥0.3 |

| Initial Thermal Conductivity(50°C) | GB/T 10294-2008 | W/(m·K) | ≤0.033 |

| Close Cell Content | GB/T 10799-2008 | % | ≥88 |

| Water Absorption | GB/T 8810-2005 | % | ≤10 |

| Air bubbles | GB/T 29047 | mm | 1/3Insulation thickness. |

| Average cell size. | GB/T 29047 | mm | ≤0.5 |

Other unmentioned matters and TDS&MSDS.Please visit our official website shundapu.en.made-in-china.com

Or please contact us for information:

>> Hot Sale 15 Colors Computer Single Head Embroidery Machine Price for Flat Cap T-Shirt Embroidery

>> 80W 100W 130W Reci Efr Yongli Tube Cloth Textile Fabric Foam Plastics Acrylics Paper Garments Shoes Handbag Gifts CO2 Laser Machine

>> High Quality Timing Chain Kit TK1511-9 for engine no.:AUK/BKH/BPK/BYU with OE No.06E109229A;079109229L

>> Electric Spray Gun Electric Gardening Sprayer

>> Hot Sale Plastic Cup Cover Paper Cup Lid Colourful PS Lids

>> 18V/20V Lithium Cordless Range Brushless 165mm Circular Saw

>> Popular facade decoration aluminum diamond sheet mesh

>> Rubber Equipment Paper Machine Air Spring for Felt Section Making Mills Kraft

>> Manual Saving EPDM Insulation Pipe Extrusion Line

>> Professional Heavy Duty Crusher for Big Pieces Hard Plastic Waste Single Plastic

>> OEM Car Electronic Riha Plastic Injection Molding Mold Mould Products Customized Gear

>> IPS LCD Display Module 15.6 Inch 1920X1080 with Touch Screen Panel Optional TFT LCD Display

>> CE China Factory Small Hydraulic Metal Bending Folding Machine 50 Ton 1600 for Sale

>> China Rock Stone Jaw Crusher for Aggregate Production Line (C1210)

>> New TPR&ABS Fishing Knife Outdoor Camping Light Fish Fillet Knife with Black Coat and Scabbard Safety Fish Knife

>> Efficient Ring Die for Sheep Feed Pelletizing Machine

>> Drop Weight Impact Deflectometer ASTM

>> Good Service Injection Mould Negotiable Riha Offer Products Plastic Mold Gear Dampers

>> Detachable Long Bishop Sleeves Lace Custom Made Mermaid Wedding Gown

>> Hot Sale Camouflage or Solid Color Ice Towel Portable Magic Water Absorbent Instant Cooling Ice Towel for Sports

>> China Foshan Anti Slip TV Background Wall Tiles

>> 20cm Ceramic Doll with Straw Hat

>> Light Weight Super Strength Fiberglass Pole for Tool Handle

>> Kubota Sr-18, Sr-20, Sr-195 Replaceable Rubber Track 330*79*42

>> HC-B077 Medical LED Lamp Microscope with Built in Digital Camera System/High Quality Microscope

>> CI858 3BSE018136R1

>> 3D Security Hologram Hot Stamping Foil Sticker for Paper/Plastic Products

>> Wisdom Aurora PRO Flashlight Intrinsically Safe UL & CSA Class I Div. 1

>> Top quality aluminum multifunction medical walking stick for old people

>> Home Embroidery Machine Computerized 1501A Single Head Cap Embroidery Machine