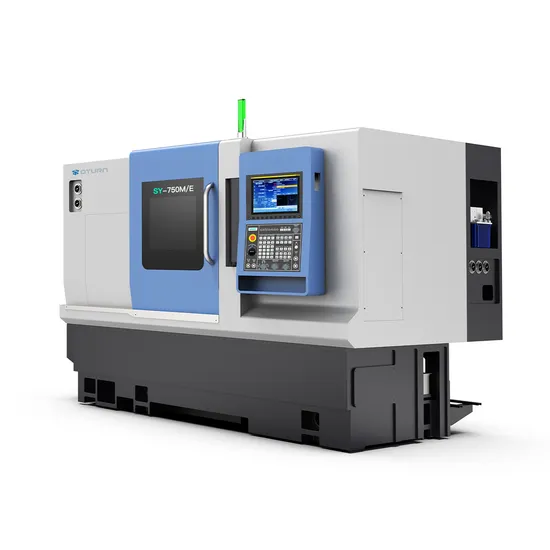

High Precision CNC Lathe Turning Center CNC Turret Lathe with Fanuc

| US$28,500.00-182,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

ESY750M

Type

Turret Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Control System

Fanuc, Siemens, Mitsubishi

Spindle

A2-6,A2-8,A2-11

Chuck

6,8,10,12inch

Tool Turret

Vdi or Bmt

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

2900*2100*2000

Trademark

Oturn

Origin

China

HS Code

8458110090

Production Capacity

1000/Year

Product Description

Product Description

Our state-of-the-art two-axis High Precision CNC Lathe Turning Center offers unparalleled efficiency by enabling simultaneous processing of both ends of the workpiece in a single clamping. This innovative approach drastically reduces manual operations, enhances output, and streamlines processes. Equipped with a second spindle, the machine seamlessly performs full turning and workpiece transfers during machining, significantly curtailing cycle times. The robust 30-degree inclined structure design ensures superior precision, outstanding rigidity, and remarkable cutting stability. Constructed from one-piece high-strength HT300 cast iron and utilizing finite element analysis, the lathe bed boasts exceptional mechanical rigidity and stability. This ensures prolonged accuracy, improved processing stability, and extended tool life. Stress relief treatment further enhances accuracy stability. Featuring a high-strength roller linear rail structure and a pre-tensioned screw transmission system, the machine exhibits enhanced rigidity performance. Its sleek and sophisticated appearance is a testament to contemporary design trends.

Elite Main Features of this Machine Tool:

1. Direct Drive Synchronous Electric Spindle: Equipped with a magnetic ring incremental encoder (sine and cosine) for 20 arc seconds positioning precision and 40 arc seconds C-axis indexing accuracy, this spindle effectively eliminates vibration with nose deflection accuracy within 0.002MM. It enhances workpiece surface finish and features a rear-mounted rotor for quicker installation and maintenance. The spindle motor's cooling system ensures thermal displacement control, maintaining a constant operating temperature. Having undergone rigorous dynamic balance testing, the spindle system excels in accuracy retention, rigidity, and efficiency, making it perfect for both finishing and heavy cutting operations. Ideal for mass production of complex shapes requiring high smoothness.

2. High Rigidity Integrated Servo Power Turret: This feature ensures rapid and precise tool changes, combined with high-speed power axis milling for exceptional turning and milling capabilities. The tool holder utilizes a high-rigidity BMT installation interface, with power transmission driven by a servo spindle motor.

3. Roller Linear Guides and Ball Screws: Precision-ground and heat-treated ball screws ensure optimal accuracy and durability. Each axis features a direct transfer structure and double-anchor pre-relay method to minimize thermal displacement, significantly boosting processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain accuracy under impact, offering smooth, low-noise operation, and extending service life.

4. Comprehensive Hydraulic and Lubrication System: Featuring high-quality hydraulic pumps, valves, and other components, this system drastically reduces the failure rate. It is designed for simplicity and reliability.

5. Taiwan Rotary Chuck Cylinder and Optional Automatic Chip Removal Device: These features significantly reduce operator labor intensity, ensuring safe and efficient production. The system is programmable, allowing for custom functions and installations according to user specifications.Special Fixture

Product Parameters

| Item | Unit | SY750M/E |

| Max. swing diameter over bed | mm | Ф600 |

| Max. processing diameter | mm | Ф400 |

| Max. processing diameter over tool holder | mm | Ф230 |

| Max. processing length | mm | 630 |

| Distance between centers | mm | 780 |

| Spindle type | / | A2-6 |

| Spindle bore diameter | mm | Ф65 |

| Max. bar diameter | mm | Ф52 |

| Max. spindle speed | rpm | 4300 |

| Direct drive spindle motor power | kw | 18/22 |

| Sub-spindle direct drive motor torque | N.m | 105-227 |

| Hydraulic Cylinder/ Chuck | / | 8" |

| X/Z axis motor power | kw | 2.4 |

| X/Z axis travel | mm | 220/700 |

| X/Z positioning accuracy | mm | ±0.005 |

| X/Z repeatability | mm | ±0.003 |

| X/Z axis rapid speed | mm/min | 24 |

| Slide rail type | / | Roller35 |

| Power turret type | pcs | BMT55-12T |

| Power turret motor | Kw | 5 |

| Max. power tool holder speed | rpm | 5000 |

| External diameter tool holder specification | mm | 25x25 |

| Internal diameter tool holder specification | mm | Ф40 |

| Adjacent tool change time | sec | 0.15 |

| Programmable hydraulic tailstock | / | Programmable |

| Max. Tailstock travel | mm | 650 |

| Sleeve diameter | mm | Ф80 |

| Sleeve travel | mm | 80 |

| Sleeve taper | / | MT#5 |

| Machine size | mm | 2900*2100*2000 |

| Machine weight | kg | 4800 |

| Cutting fluid tank volume | L | 180 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic pump motor power | kw | 1.5 |

| Lubricat tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

| Coolant water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1: How can I choose the most suitable machines?

Please provide us with your specifications, and we will select the optimal model for you. Alternatively, you can choose a specific model, or send us your product drawings, and we will help you find the most suitable machine.

Q2: What are the main products of your company?

We specialize in a variety of machines including CNC Lathe Machines, CNC Milling Machines, CNC Turning Machines, Vertical Machining Centers, Horizontal Machining Centers, Lathe Machines, and composite processing equipment for both turning and milling.

Q3: Where is your factory located? How can I visit?

Our facilities are located in Guangzhou, Quzhou, Ningbo, and Guangdong. You are warmly invited to visit us.

Q4: What are your transportation options?

We provide a range of transportation solutions including DDP, CIF, FOB, and FCA.

Q5: What are the payment terms?

Our payment terms are T/T: 30% initial payment upon order, and 70% balance payment before shipment.

Q6: What is the Minimum Order Quantity (MOQ)?

A: The MOQ is 1 set. (For some low-cost machines, the MOQ may be more than 1 set.)

We would like to know:

1. We strongly recommend providing the size and material of your workpiece for evaluation. If possible, send us the workpiece drawing so we can recommend the most suitable model for you.

2. If you require a CIF price, please kindly inform us of the port of destination.

>> Veterinary Bloodless Castrator for Cattle Bovine Swine Ovine Castration Tools Equipment

>> High Quality Plastic Floor for Chickens / Suitable for All Kinds of Chickens

>> Bulk Price High Quality Dehydrated White Onion Powder for Free Sample

>> Factory Wholesale Printing Plain Medium Size Customizable Foldable Reusable Tetoron Tote Bag Shopping Bag

>> 3 5 Liter 304 316 Stainless Steel Small Lab Scale Mixing Tank with Mixer for Lab 3L 5L 1 Gallon

>> Fully Automatic Double Wall Paper Cup Bowl Sleeve Making Machine with Intelligence Controller

>> Fibre Bundle Strength Tester / Stelometer

>> High-Speed Pet Bottle Blow Moulding Machine with Energy Savings

>> Tractor Mounted Stone Burier Rock Picker for Sell

>> High Quality Automatic Wood Cutting CNC Router Woodworking Engraving Machine 5 Axis Wood CNC Wood Router Machine for Wood Carving

>> 2020 hot sale pizza cone moulding machine/Ice cream cone machine

>> Sy-V035n Auto Lensmeter Focimeter Vertometer Ophthalmic Instrument with Good Price

>> Double Screws a/B/a Three Layers Co-Extrusion Film Blown Machine

>> 4-Axis Vertical CNC Drilling Tapping Milling Machine Center Vmc640/T6

>> Autel Evo Max4t Thermal Imaging Camera Mapper Uav Drone Night Defense Safety

>> Customized stainless steel Liquid filtration filter mesh metal filter screen

>> 1850mm Length Waterproof CE FSC Strand Woven Bambu Floor

>> Advanced oil tank technology Fatser blaster 16 faster blaster 32 vertical shot blasting

>> 12mm 14mm 16mm 18mm 20mm ABS BV CCS Dnv Certification Marine Steel Plate Sheet Grade Dh32 Eh460 Ah420 Ah32 A36 Grade a Ship Steel Plate for Bridge Steel Sheet

>> Yk-Phd4040 High Speed CNC Drilling and Tapping Machine for Connection Plates Steel Structure Fabrication

>> 200kg/Hr Pellet Feed Press Poultry Feed Float Pallet Soya Barel Make Extruder Screw and Barel Machine for Fish Soybean Extruder

>> Green Bamboo Dracaena Sanderiana Fresh Cut Flower Wholesale Bundle

>> 7.5HP 4 Stroke 212cc Agricultural Gasoline / Petrol Power Tillers Garden Rotavator Gasoline / Petrol Rotary Cultivator Tiller (GT1050B-T)

>> HONGXIN hollow tube corn extruder machine ice cream corn puffing machine

>> Snow Spray for Party Birthday Christmas

>> Wego Medical Steam Sterilizer Vertical Sliding Door Autoclave for Cssd Series

>> Sephcare food coloring powder E153 vegetable carbon black food dye

>> Rotary drum filter screen mobile rotating trommel screen for municipal solid waste machine

>> 60165 2.4V 40ah Lithium Battery, Lithium Titanate Lithium-Ion Battery

>> High Quality Body Armour Custom Molle Pouch Tactical Vest