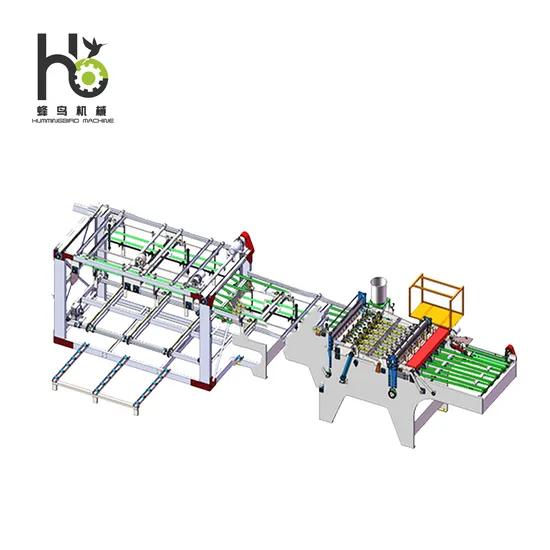

Core Joining Machine Is Mainly Used for Horizontal Splicing of Peeled Middle Boards Such as Plywood, Multilayer Board, LVL, Floor Substrate

| US$30,000.00-60,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HB-LXJ001

Type

Veneer Composer Machine

Automatic

Automatic

Certification

SGS

Control Form

CNC

Total Weight

About 6.5t

Total Power

18kw

Machine Installation Size

13m*3.1m*2.5m

Working Thickness

1-4mm

Working Speed

40m/Min

Transport Package

Container

Specification

Customized size

Origin

Shandong, China

HS Code

846591

Production Capacity

300PCS/H

Product Description

Veneer Composer Machine features simple operation and is labor - saving. It can achieve one - time automation from feeding, correction, cutting, glue distribution, splicing, stacking to pushing. The rapid cooling system enables the hot - melt adhesive line to stick to the bottom of the core veneer more evenly.High - precision servo counting results in less cutting error of finished products.After using the horizontal splicing machine, it will save a great amount of labor (saving about 70% of blank - assembling workers, about 80% of broad - repairing workers, and about 50% of putty - scraping workers), and improve the product quality and grade of the finished broad.Company Profile

Shandong hummingbird Machinery Co., LTD, located in Linyi city, Shandong province, has more than 20 years of experience in machinery production and improvement.The company established Hummingbird International Trading Company in order to expand the international market. After several years of efforts, the company's main products and equipment have been exported to Southeast Asia, the Middle East, South America, Africa and other markets.Looking forward to working with you to create, share the future!

Product Parameters

Servo horizontal splicing machine

| Motor ltem | Power | QTY | Motor ltem | Power | QTY |

| Front drive | 3kw | 1 | Push board transmission | 1.1KW | 2 |

| Rear drive | 3kw | 1 | Electromagnetic clutch | 1 | |

| Front cutting | 2.3kw | 1 | Refrigeration device | 1.5P | 1 |

| Rear cutting | 2.3kw | 1 | Dimensions | 4.2M*2.4M*2.2M 4.5M*2.0M*2.5M | |

| Lift | 2.2kw-6 | 1 | Total weight | about6.5T | |

| Intermediate transfer | 1.5kw | 1 | Total power | 18KM | |

| Drop Board transfer | 1.1kw | 1 | Machine installation size | 13M*3.1M*2.5M | |

Horizontal and vertical splicing machine

| Motor ltem | Power | QTY | Motor ltem | Power | QTY |

| Horizontal Splicing front drive | 3kw | 1 | Intermediate transfer trolley | 2.3KW | 1 |

| Horizontal Splicing rear drive | 3kw | 1 | Palletizing trolley | 2.3KW | 1 |

| Front cutting | 2.3kw | 1 | Push board transmission | 1.1KW | 2 |

| Rear cutting | 2.3kw | 1 | Electromagnetic clutch | 2 | |

| Vertical Splicing front drive | 3kw | 1 | Refrigeration device | 1.5P | 2 |

| Vertical Splicing rear drive | 3kw | 1 | Dimensions | 4.2M*2.4M*2.2M/sets 4.5M*2.0M*2.5M | |

| Vertical cutting | 5.5kw | 1 | Total weight | about10T | |

| Lift | 2.2kw-6 | 1 | Total power | 35.6KW | |

| Intermediate transfer | 1.5kw | 1 | Machine installation size | 11M*7.5M *2.5M | |

Features

Detail Accessories

Conveyor chain

Advanced control system

Cast aluminum heating plate

Brand synchronous servo

Brand servo drive

Planetary reducer

Produce

Show

Transport

>> Used Crawler Excavator Sy375 Sy305 Sy315 Used Excavators Good Price Sy245 Sy285

>> Compact Pdf Temperature & Humidity Data Logger

>> Wholesale Price 10W 18W 24W 36W Slim Frameless Round Recessed LED Panel Light

>> Ahyw Ywgs Hydraulic Metal Shearing Cutting Machine

>> aluminium profile frameless sliding windows for ghana

>> Nordic Garden Carts Outdoor Folding Pushchair Portable Camping Wagon Picnic Stall Wheels Trolley Shopping Cart Fishing Trolley Wagon

>> For BMW 3 Series F30F35 change GTS Engine Cover

>> China Factory Offer Folding Portable Display Counter

>> Rubber Floor Tile Vulcanizer for Gym Sports Rubber Flooring Mat Making Machinery

>> Pto Shaft for Kubota John Deere Tractor

>> 6X6000 8*6000 Steel Cutting Machine QC11y Hydraulic Shearing Machine

>> Home Car Hiking Camping Use Portable Emergency First Aid Kit with Medical Supplies

>> 16/18/20/24/28/32 Discs Hydraulic Heavy Disc Harrow Tractor Trailed

>> Tactical Portable Field Deployable Fiber Optic Cable Drum with LC Sc Connector

>> Car Accessories Hex Nut Flange Nut Nylon Nut Round Nut Slotted Nut Wheel Nut Insert Recessed Nuts Coupling Nut Weld Nut Wing Nut Square Nut Rivet Nut Lug Nut

>> Sunshade Louver Roof Aluminum Bioclimatic Pergola for Garden

>> hula hulla ring hoop with round ball hula hoola hoop price in pakistan

>> 60HP Rubber Tracked Rotary Cultivator; Rubber Tracks Tractors, Crawler Tractor

>> Customized Random Holes Punching Suspended Metal Ceiling Aluminum Linear Ceiling

>> Factory Cleaning Web Roller KNC7075 for Konica Minolta BH920 950 7075 7085

>> Free Fall Automatic Plastic Chemical Industrial Metal Separation Machine

>> Cast Iron Cambridge Rings / Crosskill Rings / Breaker Rings

>> Outdoor 110g Knitted Polyester Feather Flag

>> Commodity Plastic Blow Making Machine Injection Molding Machine

>> A4 Paper Cutting and Packaging Machine (2 rolls loading)

>> Duplex Board Machine Duplex Grey Board Paper Making Machine

>> Best Price Dual View 150180 Airport Pallet Cargo X-ray Baggage Scanner From China Direct Manufacturer

>> Hair Clip Cap Medical Disposable Nonwoven elastic disposable pp cap

>> Mini PC Box with I3 I5 I7 Intel Dual Core

>> Custom Auto-Loading Professional Manufacturer Pipe Laser Tube CNC Cutter Metal Tube Laser Cutting Machine with Auto Feeding