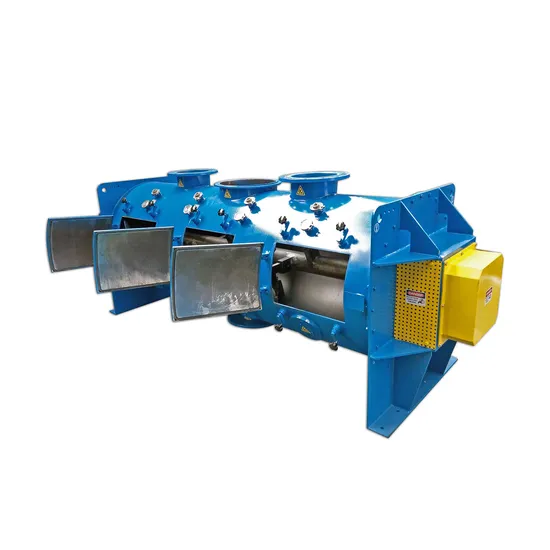

Efficient Paddle Mixer with Low Heat Generation for Temperature Sensitive Materials

| US$1,023.50-6,150.70 | 1 Piece (MOQ) |

Basic Info.

Model NO.

PTP-3000 (NA039)

Application

Granules, Powder

Application Area

Agricultural Chemicals, Chemical, Daily Chemical, Food, Pharmaceutical

Certification

CE, ISO

Condition

New

Main Material

Carbon Steel

Mixing Capacity

2100L

Mixing Drum Shape

Drum

Power

18.5 Kw

Speed Range

35 R/Min

Working

Shear Mixer

Mixer Type

Powder Mixer

Stirring Type

Forced

Layout Type

Horizontal

Operating Type

Cycle Operating

Warranty

1 Year

Construction Material

SS304; SS316L; Carbon Steel

Power Supply

220V/3pH; 380V/3pH; 415V/3pH, etc

Frequency

50Hz or 60Hz

Ex-Proof Version

Available

Motor Brand

ABB, Siemens, or Equivalent

Bearing Brand

NSK, or Equivalent

Polishing

Dull Polishing; Mirror Polishing

Transport Package

Wooden Case

Specification

CE

Trademark

PERMIX

Origin

China

HS Code

8474390000

Production Capacity

100 PCS/Year

Product Description

Product Parameters| Model | Total (liter) | Useful (liter) | kW (*) | RPM (*) | H1 (*) (mm) | L (mm) | W (mm) | H (mm) | Weight (kg) |

| PTP-5L | 5 | 3 | 1.1 | 365 | 320 | 900 | 400 | 600 | 110 |

| PTP-10L | 10 | 7 | 1.1 | 365 | 300 | 950 | 400 | 600 | 120 |

| PTP-45 | 45 | 30 | 1.1 | 90 | 700 | 940 | 850 | 1,160 | 260 |

| PTP-70 | 70 | 45 | 1.5 | 63 | 620 | 1,150 | 980 | 1,250 | 360 |

| PTP-100 | 100 | 70 | 1.5 | 63 | 620 | 1,300 | 1,000 | 1,280 | 600 |

| PTP-200 | 200 | 140 | 2.2 | 53 | 610 | 1,590 | 1,110 | 1,370 | 700 |

| PTP-300 | 300 | 210 | 3 | 50 | 620 | 1,750 | 1,140 | 1,460 | 800 |

| PTP-500 | 500 | 350 | 4 | 50 | 610 | 1,990 | 1,280 | 1,570 | 1,050 |

| PTP-750 | 750 | 500 | 5.5 | 50 | 610 | 2,247 | 1,370 | 1,670 | 1,240 |

| PTP-1000 | 1,000 | 700 | 7.5 | 35 | 150 | 2,410 | 1,450 | 1,360 | 1,450 |

| PTP-1500 | 1,500 | 1,000 | 11 | 35 | 150 | 2,780 | 1,590 | 1,410 | 1,850 |

| PTP-2000 | 2,000 | 1,400 | 15 | 35 | 180 | 3,020 | 1,700 | 1,550 | 2,550 |

| PTP-3000 | 3,000 | 2,100 | 18.5 | 35 | 180 | 3,285 | 1,860 | 1,780 | 3,100 |

| PTP-4000 | 4,000 | 2,800 | 22 | 30 | 180 | 3,710 | 2,080 | 1,900 | 4,100 |

| PTP-5000 | 5,000 | 3,500 | 30 | 30 | 180 | 3,950 | 2,210 | 2,000 | 4,700 |

| PTP-6000 | 6,000 | 4,200 | 30 | 30 | 180 | 4,110 | 2,260 | 2,100 | 5,100 |

| PTP-8000 | 8,000 | 5,600 | 37 | 27 | 200 | 4,690 | 2,480 | 2,270 | 6,600 |

| PTP-10000 | 10,000 | 7,000 | 45 | 22 | 200 | 5,720 | 2,420 | 2,315 | 9,500 |

| PTP-12000 | 12,000 | 8,400 | 55 | 19 | 525 | 7,685 | 2,640 | 2,735 | 14,200 |

| PTP-15000 | 15,000 | 10,500 | 75 | 19 | 500 | 8,000 | 2,780 | 2,860 | 15,700 |

| PTP-20000 | 20,000 | 14,000 | 90 | 15 | 550 | 8,860 | 3,000 | 3,110 | 23,500 |

| PTP-25000 | 25,000 | 17,500 | 110 | 15 | 550 | 9,900 | 3,100 | 3,210 | 27,800 |

| PTP-30000 | 30,000 | 21,000 | 132 | 13 | 605 | 10,360 | 3,160 | 3,420 | 31,000 |

1. PTP-L: laboratory size

2. kW/rpm are product dependent and might vary.

3. H1 (discharge height) can be designed according to request.

4. All specifications and illustrations are as accurate as is reasonably possible, but they are not binding.

5. PerMix reserves the right to modify the design without notice.

Introduction:

| PerMix PTP series Paddle Mixers are an innovative design derived from the well-known Plow Mixers (or Ploughshare Mixers, Plough Mixers). The Paddle provides the same mixing performance as a Plow but requires much less power consumption. Due to the less rotation speed of the paddles, the wearing of the mixing element for the Paddle is also less than the Plows. Besides, PerMix Paddle Mixers have a better performance dealing with the viscous/sticky materials, such as slurries, which is because the plough-shaped mixing elements tend to be wrapped by the viscous materials while the paddles don't. Compared with the conventional Ribbon Blenders, Paddle Mixers are superior because they are able to mix the material in a more aggressive way while keeping the similar power consumption, due to the fact that the uniquely designed paddles are more pitched than ribbons in a Ribbon Blender and move more materials in a single turn. The main difference between our PTP Paddle Mixer and PTS Plow Mixer is the mixing element: PTS Mixer uses the plough-shaped element, while PTP Mixer uses the paddle element. PerMix PTP Paddle Mixers can be used wherever the Plow Mixers are used, including but not limited to compounding, fine mixing, dispersing, suspending, emulsifying, deaerating, tempering, accelerating chemical or physical reactions, granulating, breaking down agglomerates, etc. Both Paddle and Plow are 'aggressive mixers' that are well qualified for high mixture ratio processes up to 1:1,000,000, which means the single sample of 1 ppm of a batch volume can still have the right mixture of ingredients. |

| PerMix designs the full range of paddle mixers, including the lab size (5L full) & pilot size (up to 45L full) models for Research & Development purpose. The small size machine is very helpful for customers when the ingredients for R&D are expensive, thus helping our customer to save their limited budget at the first stage. With the good performance of the lab & pilot mixer, it is easy to scale up for a medium size or even bigger one. |

| The installation of PerMix Multi-chopper in the basic PTP powder mixer enables the breaking down of agglomerates during the mixing process. Together with the mixing element, the PerMix Multi-chopper removes lumps in the initial product, chops pasty adhesives and hinders the formation of agglomeration during the moisturizing of powdered substances. The PerMix Multi-chopper is operated independently by its own motor. |

With some special modification, the PerMix PTP series Paddle Mixer can be used as a multi-stage process vessel eliminating the need for additional specialist equipment. It can be used as a mixer-dryer, mixer-granulator, de-aerator, reactor and cooler. Contact us to find more information about the unique PerMix PTPD series Vacuum Mixer Dryer. Optional Features:

Interchangeable mixing element

| PerMix can design the mixer to work with interchangeable mixing tool of both paddles and plows, supplying versatility while keeping a relatively low budget for our customer. Both plough (for PTS Mixer) and paddle (for PTP Mixer) have their own advantages: the plough-shaped element shortens the mixing time, and can easily penetrate through the dense and thick powder or paste materials, while the paddle element provides more gentle mixing with less heat generated which is good for temperature sensitive materials. |

| PerMix supplies mixers for continuous work when a large capacity per hour is needed for the same material. Continuous paddle mixers differ from batch paddle mixers in that the mass flow of the product is from the inlet of the container to the discharge at the opposite end. |

| Jacketed vessel for heating/cooling operation by steam, thermal oil, or water. ASME/PED certificate can be optional for high pressure operation. |

A variety of feeding & discharging methods can be selected by the customers. Discharging port can be by manual or pneumatic operation.

Access door

| Access doors can be designed for easy cleaning, inspection & maintenance. |

We are able to offer mixers with contact part to be built by Carbon steel, SS304, SS316/316L, Titanium, Duplex stainless steel, Hastelloy, etc. For abrasive materials we offer hardened steel as the contact part, or the mixing elements to be coated with materials such as Tungsten Carbide or equivalent.

Spray nozzle

| Liquid can be added into the powder by spray nozzles on a pipe which is installed on the top of the mixing vessel. The necessary pump and tank can also be provided by PerMix. |

Gallery

Our Advantages

Company Profile PerMix means "Perfect Mixing Technologies"! PerMix is a Chinese-Israeli cooperative venture with the famous Srugo family in Israel, who has been active and reputed in industrial mixing and processing equipment since 1954. PerMix strong advantages over other competitors are 60 years of Designed-in-Israel know-how along with competitive Made-in-China prices! (1) About SRUGO (Israel): SRUGO MACHINES ENGINEERING was established in 1954 in Argentina by the late industrialist, Jakob Srugo. In 1965 the company moved to Israel and operated from Bat-Yam. In 1977 SRUGO moved to Netivot and since then operated a modern plant with an adaptable production line to provide an efficient solution for each customer's requirements. SRUGO exported its products since 1990 to Western Europe, United States, Australia, Eastern Europe, the Middle East and several developing countries. (2) About PerMix: In 2010, Mr. Arie Srugo, the second generation of SRUGO family, sold the whole company. After three years validity period of confidential agreement, in 2013, he decided to work with a Chinese company in order to take the advantage of the lower cost with an improving technology, set up PerMix, and target this company to be present in global market. PerMix Tec Co., Ltd. is established as the professional supplier of industrial mixing and other processing equipment. Our state-of-the-art technology and know-how in this section is originally from Israel. Along with the low labor cost advantage in China, PerMix is born to be your partner for the cost effective solutions in powder, paste and liquid mixing applications. PRODUCT RANGE: We are not only able to offer the single machine with modern appearance and advanced technique, but also to offer the full line system to save your time, which is one of our strong points. With our engineers' decades of experience in this area, PerMix is capable to offer the most suitable solution for any industry that has a demand for mixing. CUSTOMIZED SOLUTIONS: Despite the standard range we are able to design the equipment according to the specific requirements of our customers. PerMix engineers evaluate the customer's mixing and processing problems in order to translate process parameters into soundly engineered and dependable mechanical equipment. PerMix welcomes the opportunity to discuss specific requirements or problems and invites customers to compare and determine for themselves which equipment is best suited for their needs. APPLICATIONS: PerMix has been building a good reputation in both local and export markets over these years. Our products are widely used to serve a variety of industries such as fine chemicals, specialty chemicals, petrochemicals, painting, ink, cosmetics, pharmaceuticals, agriculture, food, beverage, biology, nano materials, paper, adhesive, plastic, electronics, batteries, wastewater, etc. Workshop

Customers

FAQ Q: What is your price level compared with European suppliers and local Chinese suppliers?

A: Depending on the machine type and size, our price level is 30%-60% less than the European suppliers and 5-15% higher than the big local suppliers.

Q: Are you able to provide tailor-made design and production for the mixers?

A: Yes, in fact more than half of our mixers are tailor made, which is one of our strong points.

Q: Are you able to design and produce other processing equipment?

A: We are open to discuss about it.

Q: Can you provide machines to OEM customers, meaning to label their brands on the machines.

A: Yes we are doing it a lot. We have several OEM partners in the USA.

Q: Do you have agent network out of China?

A: Yes we do have agents but only in some countries, for example in USA, Germany, Poland, Spain, Denmark, Turkey, Argentina, etc. We are still looking for more agents because we believe to work with agents is the best way to do business.

Q: What is your delivery lead time of the mixing equipment.

A: Depending on the size and level of customization, but usually it is from 6-14 weeks.

Q: How do you pack and ship the mixing machines?

A: For machines don't require full container loading, we will pack them in wooden case. For FCL (full container loading) shipment, we will just wrap the machines in plastic films and fix them in the container. The shipment can be either by air or by sea.

>> Religious Life Size White Marble Jesus Statue for Church

>> Global Shining Lake Sea Rock Iodine Iodized Iodization Iodizing Salt Making Machine

>> 4lz-4.5z Grain Combine Harvester with 78kw Engine Power

>> 3A Food Grade Sanitary Cheese Rotor Pump with Motor

>> Multiple Capacities Grain Silo for Automatic Feeding System for Poultry Farm

>> 4 Gas Portable Multi-Gas Detector (LEL, CO, H2S, O2)

>> High Quality OEM Durable BBQ Leather Apron for Men

>> 2023 High Mountain Health Organic Fuding White Tea White Poeny

>> Iron Steel Grease Fitting in Metric Thread

>> Laboratory Plastic Electronic Heating Two Roll Open Mixing Mill Machine

>> Sheet Metal Mechanical Enclosure/Cabinet/Equipment Housing Computer Case Lathe Parts CNC Machine Welding Machine OEM Parts

>> Automatic Control Plastic Jumbo Bag Recycling Pelletizing Machine

>> Innovative New Materials Capillary Rheometer with Advanced Testing Capabilities

>> Large Capacity Men′s Toiletry Bag Men′s Washing Bag Simple Business Travel Handbag Storage Bag

>> Industrial Corrosion Resistance Pneumatic Control PVC Pph Valve Balls Plastic Oil Regulating Steel Safety Diaphragm Valves

>> Metal Folding Cages Wire Mesh Container Stackable Galvanized Storage Cage

>> Factory Design Can Be Customized Modeling Transparent Resin Crystal Crafts High-Grade Fortune Model Craft Gift Crafts

>> Electric Corn Wheat Beans Multi Grain Thresher Supplier

>> Dry Powder Materials Agitation Single Shaft Paddle Mixer

>> splash shield Under Tray Engine Cover Panel for KIA 2016-2017 Sportage 2.0L

>> heavy duty steel regular expanded metal mesh protection mesh for battery plate

>> Shipping Agent Sea Shipping to Netherlands Fba Shipping Amazon Dropship to Europe

>> Automatic Electronic Penetrometer Is Used for Determination of The Needle Penetration

>> Square bottom bopp laminated woven pp agricultural sunflower seeds packaging bag

>> High Efficiency Jaw Crusher for All Kind Brittle Materials with Copressive Strenght Lesst Than 320MPa.

>> High Quality Exhaust Muffler for Car Three-Way Catalytic Converter for Sale

>> Sinocharm 25-35mm A13 Frozen Sweet Whole Strawberry Fruit Halal Manufacture Wholesale Price 1kg IQF Strawberry

>> 1200mm Cookie Production Line with Tunnel Oven Wire Cut and Deposit Cookie Making Machines

>> Silicone Parts/Custom Molded Silicone Rubber Part/Rubber Sealing Parts

>> Ice cream cone shape body exfoliating mesh sponge bath puff bathroom shower wholesale bath sponge