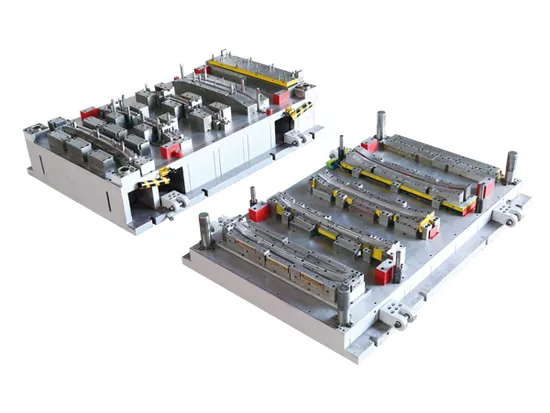

Custom OEM 20 Years Experience Custom Precision Sheet Metal Stamping Mold Stamping Die

| US$5,000.00-30,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

syh002

Material

High Carbon High Chromium Tool Steel

Processing Method

Punching and Shearing Mould

Technics

Forming Die

Process Combination

Progressive Die

Manufacturing Technology

Computer Technology

Driving Motor Type

Permanent Magnet

Mold Cavity Technology

CNC Milling

Milling Speed

High Speed

Parts Detection Method

Measurement of Three Axis NC

After-sales Service

Provide

Certification

ISO9001

Product

Vehicle Mould

Mould Longevity

300,000 - 1,000,000 Times

Product Name

Precision Metal Stamping Parts

Keyword

Metal Stamping Tool

Keyword2

Metal Stamping Tooling

Transport Package

Wooden Box

Specification

Customized

Trademark

SYH

Origin

Guangdong, China

HS Code

8207300090

Production Capacity

100 Set/Sets Per Month

Product Description

Product DescriptionCustom OEM 20 Years Experience Custom Precision Sheet Metal Stamping Mold Stamping Die

| Product Name | plastic injection mold / mould making china manufacturer | Shaping Mode | aluminum mould making china manufacturer plastic mould die maker |

| Mold Stardard | DME or HASCO | Product Material | Plastic, aluminium, zinc, die casting |

| Place of Origin | China | Design software | CAD,UG, Pro E, Solidworks |

| Cavity/Core steel | H13,S-7,S136,SS420,NAK80,P20 | Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| Mold Base | LKM,DME, HASCO, FUTABA | Surface finish | SPI standard, VDI EDM, Texture, etc |

Company Profile

Dongguan SYH Tool Co.Ltd was established in 2004, specialized in building dies and producing parts forautomotive, home appliance and office appliance industry.

We have 160 employees including 5 CAE&Process engineers and 35 designers with Autoform for simulation and AutoCAD, UG, Catia for design.Our capacity includes 20 CNC machines with the biggest one 4000x2500mm, 21 wire cutting machines,32 presses with the biggest one 2000T of the table size 6000*2500mm, 2 CMM machines,1 ATOS Triple Scan, also we have acquired IS0 9001,ISO/TS 16949 certificates to assure our best quality.

lf we have the honor of becoming one of your partners in the future, we will provide the warmest passion and thebest service to obtain the most successful relationship with you. We look forward to working with you.

Certifications

Our Advantages

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 20 years.

Q: What are your main products? A: We specialize in manufacturing metal stamping tools, metal stamping parts, sheet metal parts, CNC machining parts and welding structural parts etc.

Q: What is surface treatment do you have? A: Dacromet, powder coating, Zinc plated, nickel plated, tin plated, brass plated, silver plated, gold plated, anodizing, salt fog test etc. Due to we are focus on stamping tools and metal stamping parts, surface treatment is done through suppliers.

Q: Can I get the samples? A: Yes, sample order is available for quality check and market test, and it will be freight collect payment. If simple sample, we will not charge cost; If OEM/ODM samples, we will charge for the sample cost.

Q: What is the MOQ? A:The MOQ is 1 pcs

Q:What's the delivery time? A:The stamping tool manufacturing cycle is 20-50Days, standard stamping parts is 3 to 10 days after payment. If OEM or make the tooling, we will confirm the delivery time with you.

Q: What's your payment term? A: we advise 30% T/T deposit, the balance be paid before shipment.

Q: Do you received OEM/ODM? A: YES. We have more than 16 years OEM/ODM experience.

>> 036906051 036906051d 0369980411 Pressure Sensor for VW Bora Polo Skoda Fabia

>> Double Sided Leather Top Layer Cowhide Tote Bag Genuine Leather Women′s Bag Versatile Portable Shopping Totes Bags

>> Modern Glossy White Midnight Blue Bathroom Vanities Larch Canapa, Grey Walnut, Glossy White with LED Mirror Cabinet

>> High-Quality Construction Plywood for Building Projects

>> Walley Poultry/Meat/Dairy Products Mesh Belt/Plate Belt Tunnel Quick Freezer

>> pistachio paste top best deal pistachio

>> Hot Sales Design Portable Rechargeable Folding Neck Sports Fan with 4000mah Battery

>> Automatic Small Groundnut Peanut Picking Machine Harvest Peanut Machine

>> Wholesale high quality Auto parts FOR Chevrolet Malibu XL Gasoline pump Filter 13593759AA

>> UPVC Full Size Factory Direct Customized Rotary Check Valve

>> Triangular Felting Needle for Geo Textile Fabric

>> Ce Certificate Automatic Plastic Crusher&Shredder Knives Blade Grinder

>> DS200FGPAG1A DS200FGPAG1AHD GE Unit module controller card

>> custom printed aluminum foil pouch heat sealing mylar food holographic packaging bags

>> latest custom training wear men track suit fashion warm up Jogging suits tracksuit

>> Aluminum High quality hexagonal perforated metal mesh facade panel decorative for speaker grill

>> Mini Small Little Hydraulic Crawler Backhoe Excavator for Garden and Farm

>> Herramientas Drywall Lift Tool with CE BSCI ISO- Max Loading 68kgs

>> Hydraulic Hose Pres Crimper

>> High Quality Automatic Labor Glove Packing Machine

>> Fiber Laser Cutting Machines 1500W 2000W 3000W Economic Price Steel Metal Stainless Aluminum CNC laser Cutter for Stainless Steel Material

>> Latest Colored Waistband Elastic Interlining for Trousers

>> CNC 150cc Motorcycle Front Shock Absorber Inner Tube Centreless Grinding Machine

>> Single sliding window vinyl sliding window grill design philippines

>> 1000W/1500W/2000W/3000W CNC Metal Cutting Machine Fiber Laser Cutting Machine

>> Max. A4 Original & A4 Master Size Digital Duplicator (VR-231)

>> Large Size Column Hydraulic Clamping Radial Drilling Machine Z30100X31 Z3050X16 Z3080x25

>> Automatic Pork Skin Peeling Machine Meat Slicer Machine Fresh Beef Slicer Shawarma Machine

>> EU Stock Double Glass Jinko Solar Panels 156 Cell Solar Panel Topcon N Type Bifacial Photovoltaic Panel Monocrystalline Perc Photovoltaic 605 610 615 620 625W

>> 1800 kN Efficient Syringe Making Machine Quality Plastic Moulding Machinery