Industrial Ultrasonic Vibrating Rod Reactor Separation Emulsification Homogenization Refining

| US$500.00-1,500.00 | 1 set (MOQ) |

Basic Info.

Application

Granules, Liquid, Liquid with Suspended Solids, Powder, Viscous Fluid

Application Area

Agricultural Chemicals, Chemical, Daily Chemical, Engineering & Construction, Metallurgy&Mineral, Pharmaceutical

Certification

CE, ISO

Condition

New

Control System

Button Control

Main Material

Glass, Plastic

Mixing Capacity

30L

Mixing Drum Shape

Frame (Anchor) Mixer

Power Supply

AC

Safety Features

Anti-Slip Feet

Speed Control

Variable Speed

Speed Range

60 R/min & Above

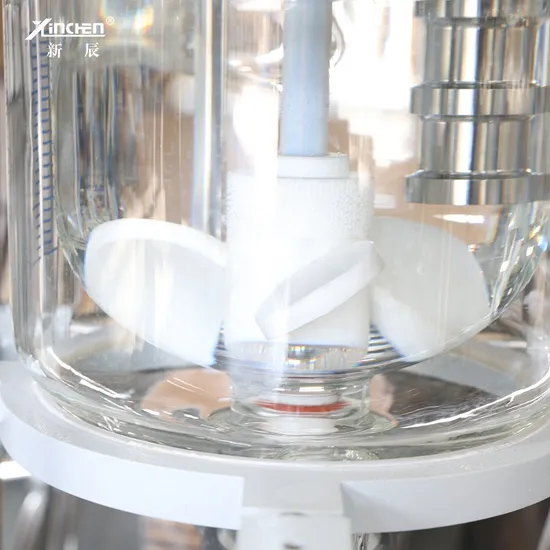

Stirring Type

Spiral

Temperature Control

With Heating

Type

Magnetic Stirrer

Voltage

110/220/380V ,50/60Hz

Warranty

1 year

Working

Convection Mixer

Temperature

-60/+200 C

Filtration Vessel

10,30, 60,80,100, 150,200 Liter

Pressure

0.096MPa or Customized

Nut

Ring Nut

Transport Package

Standard Export Wooden Case

Specification

30L

Trademark

XINCHEN

Origin

Nanjing China

HS Code

8419899090

Production Capacity

50/Month

Product Description

The Glass Reactor can be designed to be single, double or triple wall glass reactor.The reaction menstruum can be put into the inner layer to do stirring, interlayer can be connected with cold and heat source ( frozen liquid, hot water or hot oil) to do circulating heating or cooling reaction.

Under seting the constant temperature, and in sealed glass reactor, stirring reaction can be carried out at atmospheric pressure or negative pressure conditions according to the operating,and also can carry out reflux and distillation of the reaction solution.

Ultrasonic reactor is the use of ultrasonic dispersion, crushing, activation and other multiple effects to destroy the solvent structure, improve the reaction activity, disperse crushed particles, to futher reduce the diameter of the wire.

The test proved that: ultrasonic reactor play a significant role in the superfine grinding, oil emulsification extraction and dispersed in nano scale for the powder material in liquid phase. At the same time, it can accelerate the reaction, emulsifying reaction and homogeneous reaction of powdery substance. Product Parameters

| Model | XC-1L | XC-2L | XC-3L | XC-5L | XC-10L | XC-20L |

| Volume (L) | 1 | 2 | 3 | 5 | 10 | 20 |

| Jacket Volume (L) | 0.3 | 0.6 | 0.9 | 1.5 | 3 | 6 |

| Lid Diameter (mm) | 150 | 150 | 150 | 180 | 265 | 265 |

| External diameter of the inner vessel (mm) | 113 | 135 | 150 | 180 | 230 | 290 |

| External diameter of the outer vessel (mm) | 150 | 180 | 200 | 230 | 290 | 330 |

| Vessel height (mm) | 250 | 280 | 300 | 400 | 450 | 550 |

| Motor power (W) | 90 | 90 | 90 | 120 | 120 | 140 |

| Vacuum degree(Mpa) | 0.096 | |||||

| Rotation Speed (rpm) | 50-800 | 50-800 | 50-600 | 50-600 | 50-600 | 50-600 |

| Torque (Ncm) | 30 | 30 | 30 | 162 | 162 | 210 |

| Dimensions(mm) | 330*350*800 | 320*350*800 | 320*350*900 | 450*450*1100 | 500*500*1200 | 500*500*1450 |

| Power | 220V 50Hz | |||||

| Model | XC-30L | XC-50L | XC-80L | XC-100L | XC-150L | XC-200L |

| Volume (L) | 30 | 50 | 80 | 100 | 150 | 200 |

| Jacket Volume (L) | 10 | 16 | 24 | 30 | 45 | 60 |

| Lid Diameter (mm) | 265 | 265 | 340 | 340 | 340 | 340 |

| External diameter of the inner vessel (mm) | 330 | 365 | 410 | 460 | 550 | 600 |

| External diameter of the outer vessel (mm) | 365 | 410 | 460 | 500 | 600 | 650 |

| Vessel height (mm) | 730 | 850 | 950 | 950 | 980 | 1200 |

| Motor power (W) | 140 | 180 | 250 | 250 | 400 | 750 |

| Vacuum degree(Mpa) | 0.096 | |||||

| Rotation Speed (rpm) | 50-600 | |||||

| Torque (Ncm) | 210 | 300 | 350 | 350 | 400 | 400 |

| Dimensions(mm) | 500*500*1600 | 600*600*1800 | 700*700*2400 | 700*700*2600 | 800*800*2800 | 1200*900*3200 |

| Power | 220V 50Hz | |||||

| Model | NKG-0.5KW | NKG-1.0KW | NKG-1.5KW | NKG-2.0KW | NKG-3.0KW |

| Resonant frequency(KHZ) | 20±1 | ||||

| Power(W) | 500 | 1000 | 1500 | 2000 | 3000 |

| Input Voltage(V) | 220±10% | ||||

| The highest withstand temperature | -80ºC~250ºC | ||||

| Emission head diameter | 50 | 50 | 50 | 50 | 50 |

| The ultrasonic generator | 1.Fuzzy program intelligent control | ||||

| 2.DDS frequency automatic detection and tracking | |||||

| 3.DSP control circuit | |||||

| 4.Ultrasonic power putput adjustable | |||||

| 5.Power device IGBT | |||||

| 6.Continuous ultrasonic time up to 99hours | |||||

Project Photos

We professional manufacture different kinds of glass reactor systems.

We have strong design, manufacture and site installation ability.

As a manufacturer not trading company, we can supply you with high quality , best price and fast delivery service.

1.Packing method: Standard export wooden box or base on your requests.

2. Shipping method: By Express door to door, or by ship, based on your choice.

1) If delivery goods by Express, door to door service , generally about 5-7 working days reach.

2) If by air, deliver goods to your destination airport, about 5 working days reach.

3) If by sea, deliver goods to your local seaport, specific days and cost is based on different shipping line.

3. Warranty

Any broken or damages of glass parts caused by delivery, will be afforded by Nanjing Ningkai company.

>> Gp Private Logo Reusable Face Painting Practice Mode Face Paint Template Face Paint Practice Board for Body Painting

>> Love Shape Zinc Alloy Face Backside Hand Guasha Board SPA Use Massage Board Plate

>> Taijia radio shack quest sound level meter sound noise level meter

>> 4 Heads Cap Embroidery Machine

>> 1.44-2.8 Inch Small/Big Size LCD Screen TFT Module for Nk N225/Nk N220/Nk N216/Nk N206/N105 New/Nk B229/Nk N105/Nk C1/Nk B31

>> CI861

>> Tool Grinding Machine MR-13B Portable Idiot Drill Grinde

>> Industrial Peanut Butter Making Machine High Quality Nut Butter Maker Machine Colloid Mill Machinery Equipment Factory Sale

>> Automatic Corrugated Carton Paper Roll Shaftless Mill Roll Stand

>> Cosmetic Liquid Foundation Cream Making Machine Vacuum Mixer Homogenizer Emulsifier Tank

>> HY-1780B leather sewing machine for soft furniture Intensive Direct Drive, Post Bed, Double Needle Compound Feed Sewing Machine

>> 600X1200mm New White Marble Vitrified Polished Porcelain Wall Flooring Tiles

>> High Strength FRP Molded Grating Fiberglass Grating for Car Washing and Walkway

>> Hengfeng Paper - Special Thin Printing Paper for Pharmaceutical Leaflets and Bibles Factory Price

>> AAC Alc Block Making Machine From China with 2000-3000kw Power

>> Renal Care Liquid to Maintain Normal Functions Supplement of Kidney

>> Construction Machinery portable Concret Vibrator Machine with Honda Engin

>> Best Price O Neck Short Sleeve Cotton Men T-Shirt With Custom Design Solid Color Men T-Shirt

>> P-125 Single Color Screen Printer

>> PVC Farm Hexagonal Poultry Chicken Galvanized Metal Wire Mesh

>> 1ly (sx) -325 Reversible Disc Plough/Disk Plough/Plough

>> OEM ODM Factory Frameo APP 15.6 Inch Frame Share Photos Videos Digital Photo Picture Frames with Touch Screen

>> Bamboo Bread Box Creative Design Nordic Kitchen Bamboo Fiber Storage Box Pantry Organizer Kitchen & Tabletop

>> 80X80mm Thermal Receipt Paper Roll for ATM/POS Paper Roll

>> TRICONEX 4210

>> Aluminium Sliding Door Pictures from aluminium double glazed windows & doors

>> Aluminum Alloy Die Casting ODM Zinc Alloy Die Casting

>> 1000 Liters Per Hour Purification System RO Filtration Treatment Plant Water Purifying Machine

>> Auto Body Parts Car Body Kit For Camry Accessories 2018 2019 SE

>> China High Quality Popular Cheap Crawler Excavator