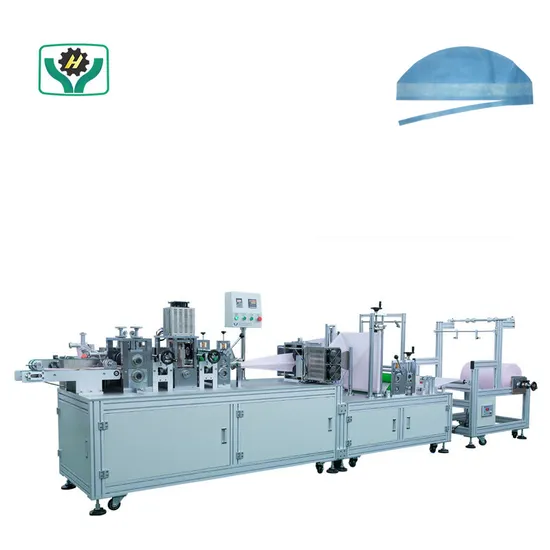

High Speed Full Automatic Operation Stabilize and Improve Product Quality Hat Making Machine

Basic Info.

Model NO.

HY500-01

Warranty

1 Year

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Name

Cap Making Machine

Fuselage Materials

Aluminium Alloy

Capacity

60-80 PCS/Min

Certification

CE, ISO9001: 2015

Customized

Accepted

Condition

New

Application

Disposable Cap

Key Word

Medical Machine

Raw Material

Non Woven

Type

Automatic Cap Making Machine

Feature

High Efficiency Automation Equipment

Purpose

Making Cap

Finished Product

Doctor Cap

Color

as The Picture

Transport Package

Packaged by Standard Export Wooden Box

Specification

5000*1144*1400MM

Trademark

HY

Origin

China

Production Capacity

30set/Month

Product Description

High speed full automatic operation stabilize and improve product quality hat making machine1. Easy for feeding material, just need one layer material to produce.

2. Adopts continuous feeding material operation method, with high efciency.

3. This machine can be used for multiple purposes which also can produce disposable shoe covers.

4. Ultrasonic weld cap edge.

5. Hobs cut product shape.

It is a specialized equipment to automatically to produce elastic type non-woven cap with the

output 60-80 pcs/min. It is applied to the Hotel, Family, Hospital and dust-free industrial. It is

automatically material feeding to the finished products.

| Machine Size | L5000*W1144*H1400MM |

| Output | 60-80 pcs/min |

| Voltage | 220 V |

| Power | 5 KW |

| Pressure | 0.6 Mpa |

| Fuselage material | Aluminium alloy |

| Special requirement | Some accessories need be changed for different product size |

maintain the machine.5. Prepare customer's feedback tracking within one week after machine installation until

customers satisfy.6. Provide one year guaranty and lifetime maintenance.

1. Q: How is the after-sale service? A: We provide 1 year guaranty and technical support lifetime. All parts of the machine can be

replaced for free within 1 year if broken. (excluding error operation)2. Q: Is it difficult to install the machine? A: The work shop shore prepare full facility such as power and air compressor. For the first

installation, our engineer will be sent to set machine and do the machine training as long as

manual instruction. If the further problems come out, we can provide video instruction as well.3. Q: What's the machine lead time? A: For the standard machines, we can delivery within 30 days. If it is customized by customer

(OEM), the lead time is 35-55 days.

>> Tensile strength 10000KN adjustable ISOFIX baby seat isofix connector

>> electric making oven pizza cone machine for sale , pizza cone making machine

>> New Alcohol Tester Factory Price Breath Alcohol Tester Portable Alcohol Rapid Test Company Use Alcohol Checker

>> Fashion Customized Knitted Beanie Soft Lady Hat

>> Custom Industrial Equipment Stainless Steel Casting Boat Parts Marine Hardware

>> Good Capacity Spring Cone Crusher Machine Price Small Stone Compound Cone Crusher Machine For Sale

>> 25/35/50/75/60/90/120/180m³ /H Engineering Construction Machinery Concrete Mixing Plant Concrete Batching Plant Price

>> 4-20 Ma Output Wall Mounted Gas Alarm Detector for Toxic Combustible Gases Monitoring

>> Heavy Duty Transmission Driveline Drive Shaft CV Pto Shaft for Agricultural Machinery

>> Compatible HP 2590 Ink Cartridge Original Quality Inkjet Cartridge for Handheld Inkjet Printer Encoder

>> 26t Amphibious Excavator with Max. Digging Reach 9.9meters

>> 2022 Ce Professional Salon Use Scar Removal Skin Resurfacing Co2 Fractional Laser Co2 Fractional Co2 Laser Portable

>> Stationary Batch Type Asphalt Mixing Plant with Capacity

>> Brand New Replacement heater for E46 3 series 64118372772

>> Automatic Carpet Bale Opener Fiber Opening Machine with CE Good Price

>> Hot Sales Education Seating School Lecture Hall Desk and Chair

>> Table Mounted Core Cutter Paper Core Machine 20 Production Capacity

>> Sv600 Online Acoustic Imaging Device

>> Mechanical Sheet Metal Shearing Cutter Machine/ Electric Plate Shear Cutting Machine

>> American standard high quality hinged windows double glass casement window

>> 18" 24" 80%20% Economy Microfiber Clothes Hygiene Dry Wet Mop Pads Strip Scrubber & Canvas Pocket& Sponge

>> High Quality Mastering Hanging Rail Design The Future Home Trend, We Bring a Revolutionary Design - Narrow Edge Sliding Door. Invisible Door, Pocket Door

>> Efficient, Intelligent, Durable and Energy-Saving 1 Cubic Meters Concrete Mixer

>> Kdvm800la 24m/Min Travel Speed CNC Milling Machine Center

>> Easy to Dismant and Maintain Handy Laser Welder

>> Custom Made Travelling Ceramic Acrylic Souvenirs Magnetic Stickers Home Decoration Photo Fridge Magnet

>> Hot Sale Diesel Engine Floating Fish Feed Pellet, Electric Poultry Chicken Feeds Grass Pellet Making Machine

>> 2021 Laser Welder Ss Carbon Steel Aluminum Alloy Profile Hand Held Laser Welding Machine Female Workers Can Weld

>> Online large face digital mens watches skmei 1167 mens led light up watches

>> 15g Nylon Spandex Sandy Nitrile Dipping Safety Work Glove