High Rigidity CNC Vertical Milling Machine for Metal Processing

| US$31,760.00-32,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HS-512

Numerical Control

CNC/MNC

Processing Precision

0.02~0.03(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE

Condition

New

Processing Time

Techincian Will Do The Assessment

Cherecteristic

High Precision and High Rigidity

Axis Number

Spindle and Sub-Spindle

Optional System

Fanuc

Transport Package

Wood

Specification

1950*1100*1700mm

Trademark

HANBS

Origin

China

Production Capacity

40 Sets/Month

Packaging & Delivery

Package Size

2200.00cm * 1700.00cm * 2130.00cm

Package Gross Weight

2000.000kg

Product Description

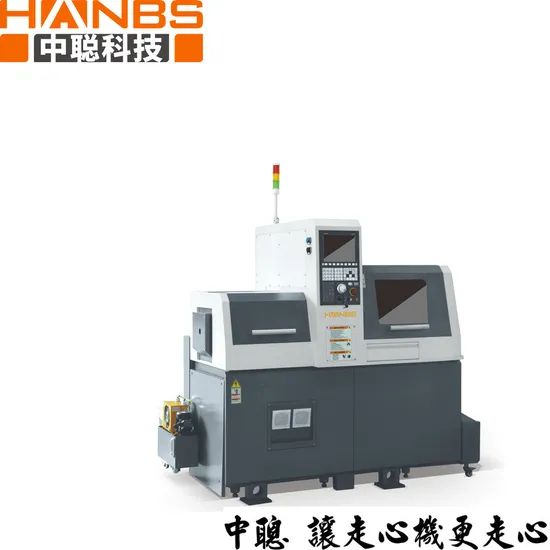

HS-512 High Rigidity CNC Vertical Milling Machine for Metal ProcessingProduct description:

1.Efficiency: With its automated and computerized process, CNC machining is much faster than traditional methods. Additionally, the machines can run continuously, reducing production time and increasing output.

2.Precision: With CNC machining, the possibility of human error is minimized, resulting in highly precise and accurate products. This level of precision is especially crucial in industries such as aerospace and medical, where even the slightest error can have severe consequences.

3.Versatility: CNC machines can produce a wide range of products by simply changing the program and tooling. This makes them suitable for mass production of standardized products as well as the production of customized and one-of-a-kind items.

4.Cost-effective: While CNC machines may have a high initial investment, they can ultimately save on labor costs and reduce waste. The precision of CNC machining also means less material is wasted during the production process.

Product Photoes

Product Information

Maximum processing diameter Φ12mm

Maximum processing length(2.5d in the mode without guide bush 60mm

Axial maximum drilling diameter Φ5mm

Axial maximum tapping size M5

Maximum spindle speed(for short-term use only) 10000rpm

Radial maximum drilling diameter Φ5mm

Radial maximum tapping M4

The maximum clamping diameter of the back spindle Φ12mm

The maximum workpiece extension of the back spindle 30mm

The maximum drilling diameter of the back spindle Φ5mm

The maximum tapping diameter of the back spindle M5

The maximum speed of the back spindle(only for short-term only) 12000rpm

The maximum take-out length of the workpiece 40mm

Side powered tool unit 3

Knife row(12*120*5+6*120*1) 5

Fixed knife(Φ25mm*4*2 for the front and back;Φ25mm*4 for the back) 13

The maximum number of tools installed as standard 21

Z1,Z2,X2,Y Axis fast forward speed 24m/min

X1 Axis fast forward speed 18m/min

Spindle center height 1000mm

Input power 7KW

Weight 1500kg

Dimensions(WXDXH) 1950*1100*1700mm Processing case

Factory

Packing&Shipping

Certifications

Q&A

1: How to select machine tools?

A: For selection, please send us the drawing of the turned part, our engineers will evaluate the drawing and provide the CNC lathe configuration that suits your needs.

2: What are your main products?

A: SmartLathe has concentrated all its resources to successfully develop the HS series of Swiss CNC lathes, including HS-820, HS-926, HS-320, HS-512 and CNC machines.

3: Where is our factory located? How to visit?

A: Our factory is located in Dalang Town, Dongguan City, Guangdong Province, China. We warmly welcome you to visit our factory.

4: How is the warranty situation?

A: The warranty period is 12 months from the date of the bill of lading.

5: Can we visit your factory before placing an order?

A: Of course. Welcome new and old friends to visit the factory.

6: Do you have any inventory?

A: Sorry, most of our machines are out of stock. We always produce according to orders.

7: What is the minimum order quantity?

A: There is only one set.

8: How is your quality?

A: We have approved the ISO9001:2008 quality management system. ISO14001 Environmental Management System, OHSAS18001 International Occupational Health and Safety Management System, and Social Responsibility 8000 (SA8000). You can rest assured of our high-quality products and the best service.

9.Do you have professional engineers?

A: Yes, we have professional engineers and designers. We can provide OEM services.

10: Can you provide customized machines?

A: Yes, we can design and manufacture according to your specific requirements.

>> pickled walnuts walnut halva dice georgian nuts packaging pitted dates with walnuts

>> Romatools Hot Style Sharp Cutting Segment 24X7.5X10mm Marble Cutting Segments for Blade D1200mm

>> 2025 Designer Shoes Sneakers Trainers Mens Women 350 700 500 Running Casual Classic

>> China Black Pepper Dryer Machine Dehydrator

>> Automatic Pet Glass Bottling Packing Plant Pure Drinking Mineral Water Filling Machine

>> White Aluminum Double Head Square LED Spotlight/Hotel/Mall 2*7W LED Downlight

>> Fast Cooling And Heating R410a 12000BTU Air Conditioner Portable Home

>> Easy Installation 90 Degree Cutting Head Rotate Bridge Saw Machine

>> CNC Vertical Lathe Machine Turning Center Universal Vertical Lathe for Water Pump Motor Shell

>> Rechargeable Candles Flameless Flickering LED Tea Lights with Remote & Timer

>> Tecjet Dtf Printer /Dtf Film Printer/Dtf Heat Transfer Printer with Double 4720 Printhead with Kcmyww Ink

>> Summer Funny Unisex Adult Outdoor Halloween EVA Skull Slippers for Men Women

>> High quality pipeline sewage treatment circular flap valve cast iron check valve

>> Supply Sealant Mixing Equipment Stainless Steel Power Kneader

>> Hanging Small Barbeque Outdoor Mini Camping Bbq Grill Picnic Portable BBQ Grill Folding Charcoal Grill

>> Customized 29/64inch 13/32inch 3/8inch 11.509mm 11.113mm 12mm 13.5mm Steel Hole Balls Copper Drill Balls

>> Carbon Full Suspension Mountain Bike Full Suspension 29 Inch

>> 1 Ton-10 Ton Manual Chain Pulley Block Hoist

>> Large Capacity Unique Kitchen Organizers Kitchenware Wash Cup Holder Black Dish Drainer Drying Rack with Removable Water Tray

>> PC 400X300 Small Capacity Hammer Crusher

>> Haichen 530t Ton Servo Series PVC Fittings Plastic Injection Molding Making Machine

>> 2020 New Patented Wiper Factory in China Soft/Beam/Flat Windshield Wipers for Good Year (10 Unite 1-only 3 adpaters cover 95% cars)

>> Green Building Material Aluminium Composite Panel ACP

>> Waste PVC Scrap Flakes Pulverizer for Powder

>> New Arrival Premium Look Stylish Luxury Leather Handbags for Women

>> MAICTOP car accessories car wheel hub wheel rims steel piano black 20 inches for lx570 oem quality

>> Vertical Milling Machine 3 Axis Milling Machine with Step Speed Milling Head

>> Air Cooling Plastic Recycling Machine Factory Price

>> Chemical Fertilizer Weed Portable Rechargeable Knapsack Dynamoelectric Electric Lithium Battery Sprayer OEM

>> Simple Slitting Machine Tile Making Machinery Product