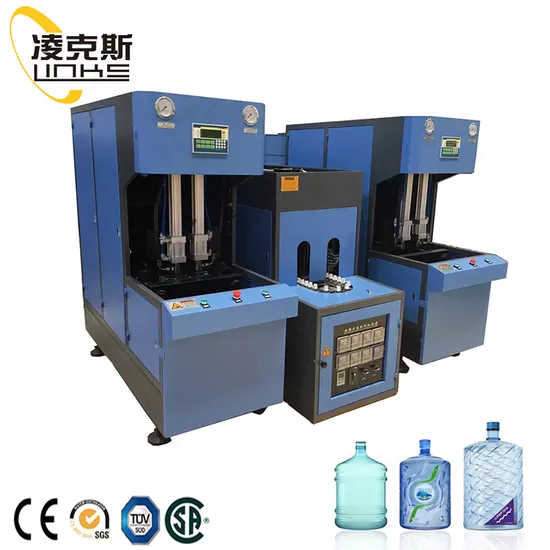

4000bph Semi-Auto Pet Plastic Bottle Blow Molding Machine

| US$9,000.00-55,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Lk-1500s

Making Method of Parison

Stretch Blow

Automation

Non-Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, QS, GMP

Model

Lk-1500s

Control System

Computerized

Bottler Material

Pet

Bottle Volume

100ml to 2500ml

Machine Capacity

600 Bottles Per Hour

Machine Installation Power

30kw

Suitable for

Water Bottle, Beverage Bottle, Oil Bottle...Ect

Workers Requests

2 Workers

Certificate

SGS, ISO, Ce,..

Weight

1200kgs

Transport Package

Wooden Export Package

Specification

ISO, SGS, CE

Trademark

LINKS

Origin

Zhangjiagang City, China

HS Code

84774010

Production Capacity

50/Month

Product Description

*IntroductionLinks Stretch Blow Molding Machine is suitable to produce different shapes of PET/PC/PE bottles. It can blow from 100ml to 6000ml bottles and is widely used to produce mineral water bottles,carbonater soft drink bottles,juice bottles,medical botties,cosmetic and oil bottles etc.

1,Infrared lamps adoped in the pre-heater ensures PET preforms being heated evenly.

2,Mechanical-double-arm calmping ensures mould being tightly closed under hight pressure and high temperature.

3,Pneumatic system consists of two parts. pneumatic acting part and bottle blowing part in order to meet different requirements for both acting and blowing. It provides sufficient steady high pressure to blowing. It provides sufficient steady high pressure to bloww large irregular shape bottles.

4,Equipped with silencer and oiling system to lubricate the mechanical pars of the machine.

5,Operated step-by-step and in semi-auto maode.

6,Wide-mouth jar and hot-fill bottles can also be made.

*Parameter

| Model | LKS-900BHR | LKS-1500BHR | LKS-400BHR | LKS-700BHR | LKS-100BHR |

| Product material | PET | PET | PET | PP | PET |

| Bottle Volume | 50-2000ML | 50-2000ML | 5-10L | 50-2000ML | 10-20L |

| Max.bottle height | 360MM | 360MM | 400MM | 250MM | 550MM |

| Max.bottle diameter | 120MM | 120MM | 220MM | 80MM | 280MM |

| Main machine (L×W×H) | 1600×600×1600 MM | 1600×650×1600 MM | 1750×750×1700 MM | 1600×650×1600 MM | 2300×850×2150 MM |

| Main machine weight | 500KG | 560KG | 800KG | 560KG | 670KG |

| Heater (L×W×H) | 1760×630×1380 MM | 1870×650×1450 MM | 1870×630×1450 MM | 4600×650×1400 MM | 2800×770×1750 MM |

| Heater weight | 260KG | 270KG | 270KG | 600KG | 270KG |

| Output | 900PCS/HR | 1500PCS/HR | 400PCS/HR | 700PCS/HR | 100PCS/HR |

| The actual output depending on the bottle size,shape and weight | |||||

*About Links Machinery

FAQ: Q: Can your company provide turnkey project from A to Z?

A: Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

Q: How can I know the quality of your machines before I order?

A: We have many projects in different countries, with the customers' permission, we can guide you to visit the factories and see the machines running. You are also very welcome to visit our company in China to see the machine running in our factory.

Q: How can we check our machines if we order the machines from you?

A: We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

Q: What is the guarantee or warranty of your machines?

A: We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

Q: For a new starter, how can you help me start and run a water or beverage bottling plant?

A: We can help you do the bottle design, label design and choose the suitable labeling and package type according to your local market. If you have confirm the factory size, we can also make the machine layout design accordingly. We can help you install the machines, train your staff how to operate, maintain the machines and even help you hire experienced Chinese engineer to work in your factory as a production manager.

>> High-Precision and High-Luster CNC Lathes Machine with Inclined Beds and High-Speed Heavy-Duty 8-Station Tool Arrangement

>> Art Parquet Floor Engineered Walnut Parquet Flooring

>> Customized Logo Multifunction Phone Booth Portable Acoustic Meeting Call Vocal Home Backyard Office Soundproof Pod

>> High Quality Fresh Fruit Canned Strawberries in Tin Glass Jar From China

>> Factory Price Automatic D92 Pneumatic Drilling Power Head Units

>> Adjustable Neoprene Knee Support - FDA Certified Compression Sleeve for Men, Women, and Children

>> Unique Design Attractive Pattern Stylish Fashion Genuine Leather Airtag Card Case Holder for Bulk Purchase

>> USA Medical Product Packaging Plastic Parts Double Color 2K Molding Mold Plastic Injection Over Molding and Injection Overmolding

>> Continuous Aeration System for Light & Fluffy Whipped Cream

>> High Quality Ultrasonic PP Media Filter Welding Machine for Water Filter

>> Customized Vertical Free Cooling Heat Recovery (Energy Recovery) Dx Rooftop Packaged Unit with Stainless Steel HVAC System Tent Air Conditioner

>> (V1038) Fashionable PU Bucket Bag with Large Capacity

>> China Factory Hg-2400ss 2400mm Carpet Nonwoven Fabric Making Machine

>> Mechanical Concrete Rebound Hammer for sale

>> 30HP Combined Rotary Screw Air Compressor with Receiver and Dryer

>> Qh Pack High Speed Corrugated Cardboard Production Line Make Machine

>> Tecjet Dtf Printer /Dtf Film Printer/Dtf Heat Transfer Printer with Double 4720 Printhead with Kcmyww Ink

>> Summer Funny Unisex Adult Outdoor Halloween EVA Skull Slippers for Men Women

>> High quality pipeline sewage treatment circular flap valve cast iron check valve

>> Supply Sealant Mixing Equipment Stainless Steel Power Kneader

>> Hanging Small Barbeque Outdoor Mini Camping Bbq Grill Picnic Portable BBQ Grill Folding Charcoal Grill

>> Customized 29/64inch 13/32inch 3/8inch 11.509mm 11.113mm 12mm 13.5mm Steel Hole Balls Copper Drill Balls

>> Carbon Full Suspension Mountain Bike Full Suspension 29 Inch

>> 1 Ton-10 Ton Manual Chain Pulley Block Hoist

>> Large Capacity Unique Kitchen Organizers Kitchenware Wash Cup Holder Black Dish Drainer Drying Rack with Removable Water Tray

>> PC 400X300 Small Capacity Hammer Crusher

>> Haichen 530t Ton Servo Series PVC Fittings Plastic Injection Molding Making Machine

>> 2020 New Patented Wiper Factory in China Soft/Beam/Flat Windshield Wipers for Good Year (10 Unite 1-only 3 adpaters cover 95% cars)

>> Green Building Material Aluminium Composite Panel ACP

>> Waste PVC Scrap Flakes Pulverizer for Powder