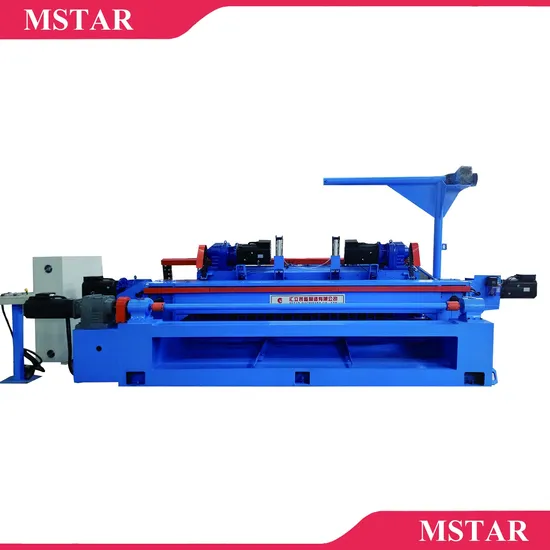

Mstar Hot Seeling Lasted Advanced 8FT Veneer Peeling Machinery

| US$40,000.00-45,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

8ft

Type

Peeling Machine

Automatic

Automatic

Certification

CE

Brand

Mstar

Motor

Servo Motor

Gearbox

Best Gearbox

Paiting

Environmentally Friendly Water-Based Paint

Treatment

Cast

Weight

Heavy Duty

Model

Latest

Steel Roller

Latest Type

Size

8FT

Peeling Veneer

Core Veneer

Transport Package

Container

Specification

mainly steel

Trademark

mstar

Origin

China

HS Code

84659600

Production Capacity

400set/Year

Product Description

Company ProfileMSTAR MACHINERY CO., LTD is located in Linyi city of Shandong, China, and it is a modern professional enterprise and specialized in research, development, production and distribution of woodworking machineries. Our leading products are high speed spindleless veneer peeling line, sanding machine, hot press, saw, debarker and so on. Our high speed automatic veneer peeling line has become the benchmark of the peeling industry, with the advantageds of high efficiency, energy saving , time saving and labor saving.

By offering qualified products, perfect services and honest sales, we earn the applause from the world, We sincerely look forward to cooperate with you! Product Parameters

Parameter | Value | Notes |

Length of the Roller(mm) | 2750 | |

Power of Double Roller(kw) | 15kw X 2 | AC Servo induction motor |

Power of Single Roller(kw) | 15kw X 2 | AC Servo induction motor |

Power of Screw Feed(kw) | 11kw | AC Servo induction motor |

Power of Rotary Clipper(kw) | 5.5kw | AC Servo induction motor |

Power of Rubber roller (kw) | 5.5kw | AC Servo induction motor |

Total Power(Kw) | 82kw | |

Roller Reducer | Helical Gear Reductor X 4 | R97 |

Screw Feed Reducer | Helical Gear Reductor X 1 | R97 |

Veneer output speed(m/min) | 50-80 m/min Adjustable 50-80 m/min | |

Blade (mm) | 2750*180*16 | |

Screw Diameter(mm) | 90mm | |

Max opening(mm) | 500 | |

Minimum Log core | 35mm | |

Thickness(mm) | 0.8 - 4.0 | |

Clipper width(mm) | >= 400 mm | |

Control Unit | Peeling Speed Adjust System Closed loop Servo control | PLC + Touch Screen PLC+ MD810 |

Size(mm) | 6500*2200*1600 Length()*Width()*Height() | |

Weight(kg) | 15000 |

Detailed Photos

SINGLE ROLLER AND DOUBLE ROLLEER GIVEN SPECIAL TREATMENT

MORE WEAR-RESISTING

VENEER MORE SMOOTH

CYLINDERS ON SIDES IN CASE PEELING LOG IS NOT AT THE RIGHT POSITION

CYLINDER WILL PUSH THE LOG AUTOMATICALLY

MACHINE IS CASTED, HEAVY DUTY MACHINE AND MACHINE IS MORE STABLE FOR LONG TIME RUNNING

SHOWING TIME

LUBRICATED SCREW AND NUT AND PEELING SLIDER

TEAM & CULTURE

"One vision, one team, one goal."

"Teamwork makes the dream work."

"Together, we rise."

OUR VISION

"United, we conquer."

"Collaboration unlocks potential."

"Teamwork makes the dream work."

"One vision, one team, one goal."

FAQ

Q1:Can you customize products for clients?

A1: Yes .We can customize and produce woodworking machines according to the customer's requirements or drawings.

Q2:What about your products quality?

A2: If you order, we guarantee the quality is same with what you see. In case of quality problem, we can sign agreements and our company will perform the duties.

Q3:How can we trust your factory?

A3:We recommend that you come to our factory to see the goods,to verify the real situation of the products, and know more about our factory.

Q4:Why does the price often change?

A4:The configuration of motor and control system determines the change of price. Different quality determines different price.

Q5:What about the contract signing?

A5: If you're satisfied with the products and our service, you can sign the contract with us, pay the deposit Then we'll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

Q6: How about delivery?

A: when the product is ready, it can be delivered to you after your full payment. We'll provide technical guidance.

Contacts

I believe that by understanding our products,you will recognize and want to buy it,our products will not disappoint you, so do not hesitate to act quickly,contact us.

Service during the sales

1) Inspect the machine before leaving the factory

2) Oversea install and debug the equipment

3) Train the first-line operator

After sales service

1) 24 hours online service

2) Provide the VIDEO with install and debug the equipment

3) Provide technical exchanging

>> Continuous Herb Refinery Short Path Molecular Distillation System

>> plastic water well covers composite manhole cover price square manhole cover with hinge

>> Bird Pigeon Plastic Spikes Anti Birds Control

>> Manufactory Direct Gear Latex Glove Making Machine

>> OEM 96626982/96626981 Auto parts RED light rear bumper lights for CHEVROLET CAPTIVA 2008

>> Tractor Mountched Deep Soil Loosening Cultivator/Deep

>> 4040 frp membrane shell 2540 membrane housing frp membrane housing

>> Linggao 35kHz 1200w ultrasonic handheld control welding machine high quality handheld portable high precision ultrasonic welder

>> Good Heat-Resistance Function PU Foaming Machine Dy-Hgc7403-XL

>> Meisemobel Double Bed Storage King Size Multifunctional Smart Bed Frame Adjustable Electric Base Sn1.5

>> Memory Foam Orthopedic Car Seat Backrest PU Lumbar Support

>> Underpant Tight Women′ S Captain Hot Shorts Seamless Boys Health Nurse Panty Disposable Trade Woman Underwere Women Underpants

>> Black Perforated Metal Mesh Pen Holder Desk Organizer Pen Cup

>> High Quality Resistant WPC Stainless Steel Stamping Decking Clip Part

>> Sand sifter beach sand cleaner price for sand cleaning

>> China Manufacturer Diesel Powered Hay Cutter Stalk Cutter Chaff Grass Cattle and Sheep Feed Chopper

>> Ep / Nylon Rubber Conveyor Belt for Mining Coal

>> 2024 China Fresh Carrot

>> Kangton 1400W Cement Mixer Machines

>> 2018military Tactical Shoulderl Laptop Backpack

>> South America hot selling floating fish feed extruder

>> Sea Freight Logistics to USA: Reliable Door-to-Door Delivery From China to USA, Expert Freight Forwarder & Shipping Agent

>> Custom Colors SAE 100 R7/R8 Thermoplastic Nylon PU Rubber Hydraulic Hose

>> CP450T-ETH

>> Tpm3030 CNC High Speed Drilling Machine

>> New Design LED GU10 Spot Light Linear Driver Light

>> 120L Plastic and Rubber Banbury Mixer Internal Mixing Machine for Rubber Kneading

>> Stainless Steel Carbon Steel 8.8 Class Anchor Bolt Hexagon Bolt Hex Socket Bolt Stud Bolt Carriage Bolt T Bolt Nuts Bolts Furniture Bolt China Fastener

>> Holdwell Replacement Sugarcane Harvesters Spare Parts for John-Deere CH570 CH670

>> 75kw Efb Crusher Machine