Food Additives Non Gravity Mixer Nutraceuticals Powder Mixer Food Granules Mixer

| US$15,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

SHZL

Application

Granules, Powder

Application Area

Chemical, Food

Certification

CE, ISO

Condition

New

Stirring Type

Spiral

Working

High Speed Mixer

Barrel Volume (L)

100-20000L

Electric Control

Button / PLC

Heating / Cooling

Jacket

Bearing

Supporting NSK, etc

Voltage

220-600V

Electric Component

Delixi..Foreign&China Top Brand

Vacuum Drying

Optional

Cleaning Door

Optional

Material

SS304, SS316L, Ss321L

Range of Spindle Speed(r.p.m)

0 - 60 r.p.m

Power (Kw)

18.5 Kw

Explosion Proof

ATEX

Motor Brand

ABB/Siemens/Teco

Mixing Drum Shape

Drum

Operating Type

Continuous Operating

Transport Package

Wooden Package with Steel Frame

Specification

Customised

Trademark

SIEHE

Origin

Shanghai, China

Production Capacity

20 Set/Sets Per Quarter

Product Description

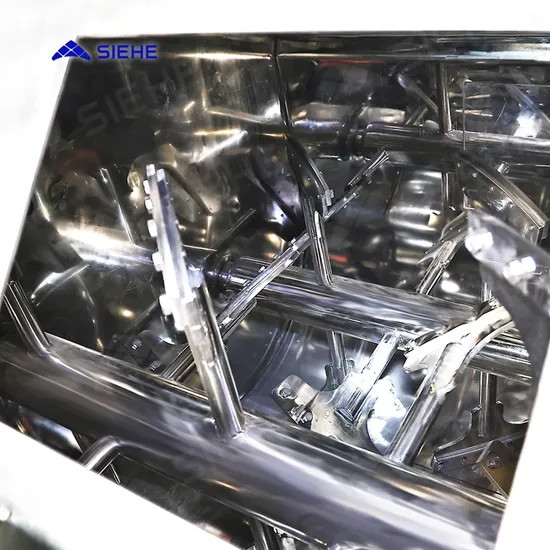

Product DescriptionHorizontal Non Gravity Mixer is a Korean-technical late-model mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. Agitators, designed in special angle, rotates in same but opposite direction and shows a nice mixing, smashing, dispersing results. It is widely used in powder-powder, powder-liquid, powder-particles mixing. It is also able to used for materials in different specific gravity and particles in a wide range of sizes.

| Materials Specific Gravity | ≤3g/cm³ |

| Production Capacity | 100-20,000L |

| Application Industry | Suitable for the mixing of food, pesticide, dye, chemical industry, plastic, lithium battery, ceramic, chemical fertilizer,rubber, mortar and etc. |

| Appilicable Materials | Powders with fluidity whose specific gravity is up to 5g/cm³, liquid content is up to 20%, such as flavoring, pesticide, reactive dyes, water-free dirt, lithium cobalt oxides battery material and etc. |

Twin shaft paddle type mixing agitator;With higher mixing efficiency and uniformity. SMALL BATCH HORIZONTAL NON GRAVITY MIXER

100L design volumeAll stainless steel mixer;With support legs and side operation door. MIDDLE BATCH NON GRAVITY MIXER

500L-1000L Design volumeMachine materials can be customized with SS304/SS316L or carbon steel;

With chain type drive system. LARGE CAPACITY NON GRAVITY MIXER

2000 -20000 L Design volumeTwin shaft reducer for main shaft driving;Feeding ports as well as discharge ports all can be customized.

Rich Experience & Excellent Design Aptitude Products are designed according to the characteristic of raw and finial products materials and manufacturing process(i.e. Pressure requirement, proportion of solid and liquid) to meet the requirements in driving device, operability, leak-proofness and etc. areas. Reliable Driving Device Driving motor uses SIEMENS, ABB and etc international brands products, output torque can be output by direct-combination, chain-wheel combination, hydraulic couplers and etc.

Reducers uses R series umbrella gear reducer (or K series spiral cone gear reducer) with high usage coefficient, large rated torque, high conveying rate, safe, long service life, low noisy, low risk of failure, easy to maintenance and etc advantages. High Efficient Mixing Device Multi-experiments and design for the angle and cross area of blades contributes to a reasonable agitator with high efficient.

Adjustable extension blades are in option, which is easy to change or decrease the gap between the blades and cylinder. It is good for wording condition with large wear. Nice Assistant Component Assistant components are in option, such as: coil steam heating jacket, honeycomb anti-pressure jacket, recycle-medium jacket, real-time sampling valve, high speed fly-cutter, temperature detector, weighting system, dust collecting system, vacuum drying system and etc.

Spray and atomizing device are in option to spray little liquid which will mix the liquid into powders better. Spraying system consists of pressure source, liquid storage tank,spray device.Industrial Applications

Company Profile

SIEHE GROUP established in year 2009, start with liquid machine manufacturing. After more than ten years of efforts, SIEHE Group has developed into large-scale machinery industry group company. lts headquarter is located in Honggiao, Shanghai, China. lts production bases are in Jinshan, Shanghai,Wuxi and Yangzhou in Jiangsu, with a total plant area around 32000m2. The production bases are equipped with more than 160 sets of advanced production processing and testing equipment including: turning and miling center, large gantry five- axis machining center, horizontal five-axis boring and miling machining center, Vertical five axis machining center, vertical CNC lathe machining center, trilinear coordinates precision measuring instrument, image measuring instrument precision altimeter etc.. With strong production and quality control capacity, SIEHE group carries out product design, processing,assembly and testing in full accordance with the lSO9001 quality management system, and has passed professional institution certification.

Production Equipment

Five-axis Gantry Machining Center Turning and Milling Center CNC Boring and Milling Machining Center

CNC Vertical Lathe Vertical Machining Center CNC Five-axis Gantry Machining CenterCustomer Photos

Certifications

>> Customized Pmd Series CNC Hydraulic Gantry Movable Metal Plate Drilling Milling Machine

>> Factory Supply High Quality 100% Natural Ganoderma Lucidum Extract Herb Extract Plant-Extract

>> C26800 C28000 H62 H68 L80 L90 C2600 Brass Plate

>> Multifunction Miter Concrete Rock Bone Wall Saw Cutter Machine

>> Chinese Suppliers 800W Flex Slot Platinum Hot Plug Low Halogen Power Supply Kit

>> Compact Construction Elevator by Te Wei, Robust Crane Machinery for Versatile Use

>> Four Wheels 300W Handcapped Folded Electric Mobility Scooter Parameter

>> Wild Land Hemp Rope LED Camping Light for Camping

>> Commercial Industrial Bakery Equipment Bread Cutting Machine Bread Slicer

>> Power Ee 10-35kv 30-25000kVA Oil Energy-Efficient S13 Transformer S13-M S11-M

>> New Harvest Low Price Carrot Farm Fresh Juicy Sweet Carrots

>> Conventional Large Lathe Heavy Duty Manufacturing Processing Machinery Bed Width 780mm Tail Stock Sleeve Travel 300mm

>> 1668800505 L 1668800605 R W166 ML Class Front injection molding Fender inner For MERCEDES BENZ

>> Customizable Batching Plant Capacity to Suit Various Construction Needs, From Small to Large Projects

>> RTS,GTR style front grille for benz e class w213 front bumper grille

>> Customizable Image Quality 4K Recording Videos 16X Autofocus System Photography Digital Camera

>> Hongtaipart Compatible Fuser Drive Gear Ab01-2096 Ab01-2116 Ab012096 Ab012116 for Ricoh MP C4502 C4503 C5503 C6003 Mpc4502 Mpc4503 Mpc5503 Mpc6003 Printer Gear

>> Horizontal Height Angle Measure OLED Laser Rangefinder Binocular

>> Kengfai 1/18 G-Paton American Alloy Car Model

>> Leg Stretcher Outdoor Multi Gym/Gymnastics Fitness Machine/Equipment for Sports

>> High Performance Farm Tractor Disc Plow for Sale

>> High-Efficiency Foam Sheet Extrusion Machine for PS Material Production Line

>> Tempered Glass Side Panel MID-Tower Gaming PC Case

>> 2 Years Warranty Customized High End Agricultural Oil Bath Bearing for Disc Plow

>> Price 10% off Doudle Door Food Bread Steamed Steamer Cabinet Machine Central Kitchen Steam Heating Rice Cooker Equipment

>> Large Capacity Heavy Duty Blender with Safe Material

>> Multi-Purpose Lathe Machine C6241/1500

>> MAICTOP auto spare parts sliver wheel hub rim FOR LANDCRUISER 200 2016 new model 18/20 inches

>> Custom Christmas Santa Sack PP Non Woven Drawstring Gift Bag

>> Kdvm855L 24 Tools Capacity CNC Milling Machining Center