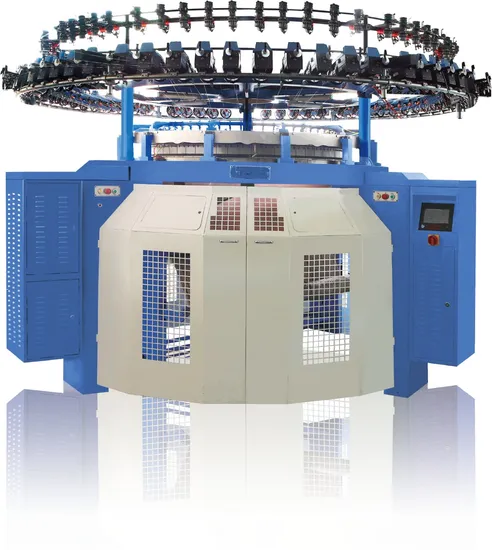

Single Jersey Terry Jacquard Circular Knitting Machine

| US$25,000.00-30,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

RSDT-M

Knitting Machine Cut

E24

Knitting Style

Weft

Knitting Method

Single

Needle Style

Latch Needle

Needle Bar Style

Circular Knitting Machine

Computerized

Computerized

Condition

New

After-sales Service

Installation, Operation Training

Cylinder Diameter

34"~52"

Gauge

18g~24G

Feeders

42f~60f

Origin

China

HS Code

84471200

Production Capacity

100 Sets Per Month

Product Description

Type:

This is a jacquard knitting machine for terry / plush.

Features:

It equipped with electronic needle selection in the cylinder, any complex textrue can be knitted.

The design data can be conveniently inputted and stored via USB device.

The heart parts of the machine.

Product Parameters

Technical data:

| Machine Type | Single Jersey |

| Function Device | Electronic Jacquard |

| Cylinder Diameter | 34" ~ 52" |

| Machine Gauge | 18G ~ 24G |

| Feeders | 42F ~ 60F |

Product Application

Structures:

This machine can knit a wide variety of single jersey plush and terry with jacquard pattern.

Application:

Applied in multiple fields such as sports & leisure, nightwear, outerwear, curtain, home textile, mattress etc.

Our Advantages

High Manufacturing Capacity:

Annual production of 1500 ~ 2000 circular knitting machines and related accessories.

Advanced In-House Manufacturing:Our factory is equipped with high-precision machinery, including gear hobbing machines, CNC machining centers, and CNC vertical lathes from Germay and Japan. By producing all core components in-house, we maintain strict quality control and ensure exceptional precision, resulting in superior machine performance.

Premium Materials for Durability:We insist on using high-quality steel and alloy materials for all components. This Commitment to premium materials significantly extends the machine's service life and enhances durability.Cutting-Edge R&D and Engineering:With our dedicated research and development center, experienced design engineers, and skilled technician team, we continuously refin our technology. As a result, our machines deliver higher precision, allowing you to knit superior-quality fabrics with greater efficiency.

Quality Service:

Our professional team provides pre-sales and after-sales services such as product consultation, technical guidance, installation services, and operation training.

Production Equipment

Core Component Processing

>> 18-26ton Excavator Hydraulic Hammer Breaker

>> Semi Automatic Double Heads PVC TPU EVA High Frequency Welding Machine for Gloves Labels

>> Full Auto Bottle Making Machine 0.1-2L Pet Bottle Blowing Machine for Soft Drink with Fast Delivery

>> Chaoxu Plastic Suitcase Making Machine in Production Line

>> TV640 CNC Vertical Machine Center for Metal Drilling Machine Tapping Machine High Speed High-Accuracy CNC Milling Machine

>> New Intelligent CNC Busbar Processing Punching and Shearing Machine

>> Cement Retarders Water Reducer Agent Textile Additive Concrete Mortar Sodium Gluconate Powder

>> Spiral Lucky Bamboo Dracaena Sanderiana 30cm-100cm Indoor Plant Flower

>> Automatic Waste Plastic PP Bags PE Film Recycle Washing Machine

>> Newest Battery Wireless 6*18W LED PAR Light Wall Wash Light

>> Ribbon Mixer for Food Wheat Powder Blending Machine Seasoning Flour Blender From Brightsail

>> Tongfei Mcwl Laser Water Cooling Machine Mcwl-10tr-12z-1225

>> Customized Outdoor Inflatable Fence for Bumper Cars

>> Plastic ABS Washing Capacity Portable Mini Wahing Machine Shell Injection Mould

>> precisiones sobre ensayos de integridad

>> Ozonizer Water Treatment Ozone Generator Water Purifier

>> Best Sales Excellent Rotational Molding Machine

>> Wholesale Hot Sell 12 Inches Baby Doll Educational Cute Silicone Doll Children Kid Reborn New Doll with Environmental Protection Materials

>> Customized High-Quality Stainless Steel Flange for Engine Parts

>> Flexible CE Solar Cable 6mm for DIY Solar Panel Installation

>> factory machine plastic welder 15kHz 2600W price ultrasonic welding bonding machine for sale

>> Superior Waste paper Vertical hydraulic packer Bottle Recycle Baler

>> High Speed 4K@60Hz 3D UHD2160p Type C to HDMI Cable for 3D Television

>> Small carbon black briquette machine press black fines from natural gas heavy fuel oil rubber waste tyre pyrolysis to briquettes

>> Industrial Three Cylinder Sand High Temperature Dryer Industrial Sand And Ore Used Rotary Drum Dryer Working For Animal Feeds

>> Universal Outdoor Swimming Boating Skiing Driving Vest Survival Suit Polyester Life Jacket for Adult Children with Pipe S -XXXL

>> Modern Style Small Size Pre Rinse Faucet Pre Rinse Bar Faucet Pull out with Sprayhead

>> China Supplier High End Custom Printed LOGO Cardboard Clothing shirt packing box With Ribbon Lid and Base Gift Box

>> Transparent Colorful Waterproof Double Shoulder Students Guitar Instrument Protective Jacket Backpack Case Pack Bag (CY3690)

>> Intermediate Speed Advanced Speed Double-Sided Rib Circular Knitting Machine Textile Machines Sweater Knitting Machine