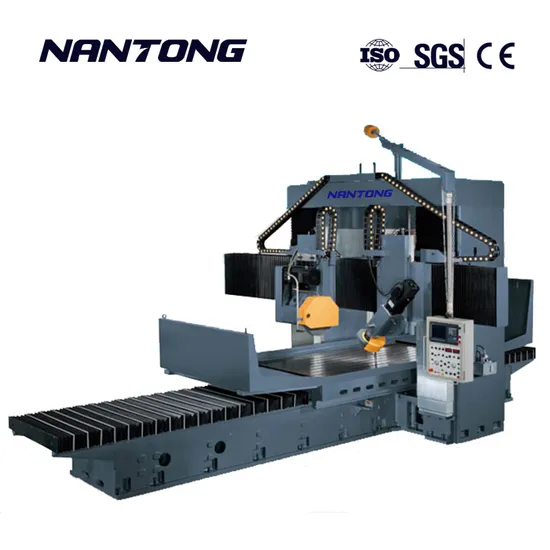

Nantong Universal Type CNC Gantry Milling Machine

| US$15,900.00-95,600.00 | 1 Piece (MOQ) |

Basic Info.

Structure

Gantry

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Transport Package

Container

Trademark

nantong

Origin

Nantong

Production Capacity

300 Sets/Year

Product Description

Machine Parameters| Model | Unit | SKX2016 | SKX2500 | SKX3020 | SKX4025 |

| Travel | |||||

| X axis | mm | 2,200 | 2,700 | 3,200 | 4,200 |

| Y axis | mm | 1,600 / 2,000/2500/3000 | |||

| Z axis | mm | 800(1,000-opt.) | |||

| Distance from spindle nose to table | mm | 150 - 950(150 / 1,150-opt.) | |||

| Distance between two column | mm | 1,700 / 2,100/2600 | |||

| Working table | |||||

| Table Length | mm | 2,000 | 2,500 | 3,000 | 4,000 |

| Table Width | mm | 1,600 / 2,000 | |||

| Table Load | kg | 6,000 | 7,000 | 9,000 | 10,000 |

| T- Slot (Width x Number x Pitch) | mm | 22x7x180 / 22x9x180 | |||

| Spindle | |||||

| Spindle Taper | - | BT-50 / ISO-50 / CAT-50 | |||

| Spindle Speed | rpm | 3,000(6,000-opt.) | |||

| Spindle motor(cont./30 minutes rated) | kw | 18.5 / 22 (22/26-opt.) | |||

| Feed | |||||

| Rapid Traverse(X/Y/Z) | m/min | 12 / 12 / 15 | 10 / 12 / 15 | ||

| Cutting feedrate | mm/min | 7,000 | |||

| Accuracy | |||||

| Positioning Accuracy | mm | ±0.005 / 300 ; ±0.015 / Full travel | |||

| mm | P0.03 | P0.035 | |||

| Repeatability | mm | ±0.003 | |||

| mm | 0.025 | 0.028 | |||

| ATC | |||||

| Tool magazine capacity | pcs | 32 (24/40/60-opt.) | |||

| Max. tool size (full pocket/next pockets empty) | mm | Ø125/245 | |||

| Max. tool length | mm | 350 | |||

| Max. tool weight | kg | 20 | |||

| Others | |||||

| Power required | kva | 65 | |||

| Pneumatic input pressure | kg/cm2 | 6.5 | |||

| Machine net weight | tons | 20 / 22 | 22 / 24 | 24 / 26 | 28 / 30 |

| Floor space (LxWxH) | m | 8.5x5.1(5.5)x4.7 | 10.5x5.1(5.5)x4.7 | 12.5x5.1(5.5)x4.7 | 15.2x5.1(5.5)x4.7 |

Machine Configuration

| Automatic lubrication system |

| Spindle oil cooler |

| Air blast through spindle |

| Manual Pulse Generator |

| Working lamp |

| 3-color alarm lamp |

| RS-232 interface |

| Heat exchanger for electrical cabinet |

| Water gun and air gun interface |

| Cutting coolant system |

| Twin auger chip removal system |

| Belt type chip conveyor with cart |

| X axis Heidenhain Linear Scale |

| Sub-table |

| 3 axes manual pulse generator for mold processing |

| Coolant through spindle at 20/40/70 bar |

| Coolant through tool holder interface |

| Air conditioner for electrical cabinet |

| Transformer |

| Oil skimmer |

| Oil mist collector |

Company Introduction

NANTONG YIJI MACHINERY CO., LTD

Founded in 1988, Nantong YIJI Machinery Co., Ltd specializes in manufacturing high-precision move column CNC machine centers, floor-type boring machines, CNC gantry milling machines, automatic solutions, and professional machine tools. We stand out by embracing the philosophy of 'Quality is essence, excellence, full participation,' continuously enhancing the esteemed 'YIJI' brand. With specialized design, mature production craftsmanship, strict QC management, rapid integrated solutions, and exceptional after-service, we have earned the trust of numerous clients. Our market share has expanded significantly, with a diverse product range enjoying robust sales across 30 countries in Europe, America, and Southeast Asia, earning an excellent reputation. We hold import/export rights, export product licenses, CE certification, and ISO9001 quality system certification.

Innovation knows no bounds. Techniques shape the future. We are committed to providing you with professional technology, superior quality machines, and outstanding service.

Our Service

Warranty & After-sale service

1. 24-hour technical support via email or telephone.

2. Provision of extra accessories for the machine and customized program services based on your drawings. Special designs are welcome.

3. All our products come with a 12-month warranty.

4. Damage caused by human factors is an exception.

5. We provide materials and technical support to help our customers resolve issues efficiently.

We will cover the delivery costs for any repair, return, or replacement cases.

We welcome your inquiries!

>> Indicator Bristles Rotating Advanced Replacement Head for Electric Toothbrush

>> Dry Type Tube Ball Mill for Clinker Grinding

>> Wholesale Mini Poultry Feed Mill Machine

>> Cotton Long Dress Cover Bag Reusable Garment Packaging Bag for Promotional Custom Folding Zip Suit Cover Garment Bag

>> 2021 Farm Machine Tractor 100HP NF Tractor Rubber Track Rubber Crawler Tractor Nfg 1002 for Agriculture

>> 2025 New 300cc K7 Racing Go Kart Gasoline Off Road 4X4 Electric Start Dune Buggy

>> Second Hand Zoomlion Chassis 52 M Good Used Concrete Pump

>> electric liftgate lift Rear Power tailgate Door for skoda kamiq 2018+

>> Used Kobelco Excavator Sk200 Sk200-8 Sk140 Sk210 Sk330 Hydraulic Crawler Excavator Japan Made

>> New Spring and Autumn Coat Men′s Casual Suede Baseball Jacket American Street Style Embroidered Baseball Collar Jacket

>> Custom black metal security best steel iron fence entry front double doors

>> 2022 Wholesale ROEL Rainbow Mechanical Watch Automatic Mechanical Movement Luxury Fashion Waterproof Stainless Steel

>> 1/2′′ Inch 550n. M Impact Wrench Torque Brushless Motor 20V Cordless Rechargeable Battery Garage Tools for Auto Car Tyre Tire Repair Services

>> Industrial-Grade Limestone and Raw Stone Ball Mill Solutions

>> PVC Wine Capsules Plastic Printed Design Tear-off Strip Seal Wine Bottle Capsules

>> Data Communication HDMI AV Cable with Net Ferrite (pH6-1209)

>> Factory price sweet corn threshing machine on sale

>> Steel Structure Peb Fabrication Machine CNC H Box Beam Drilling Machine for Metal Beam Profile

>> Lockable Plastic Rodent Control Rat Trap Box Mouse Bait Station

>> Wholesales Reusable Sport Ice Bag Pack, Compress Cloth Ice Bag with Wide Mouth, Cold Therapy Fillable Bag to Reduce Pain

>> Kexint 24/48/72/96/144/288 Core Ribbon Optical Fiber Cable Duct Central Tube

>> Combine Harvester 4lz-5.5A/6.0A

>> OEM Luxury Pillow Top Hotel King Queen Size Bed Sponge Memory Foam Roll up in a Box Pocket Spring Mattress

>> Economical China-Europe Railway DDP/DDU Train Shipping with 30-40 Days Arrival

>> High-Capacity Crusher Shredder for Aluminum Profiles, Rubber Tires & Wood Logs

>> Waterproof Disposable CPE/PP/PE Shoe cover Plastic Shoe cover Funda de zapato

>> Excellent Quality Supermarket Shelves Retail Display Store Gondola Shelving Supermarket Shelving

>> Sialwings Workout Custom Women Yoga Booty Shorts Gym Fitness Scrunch Butt

>> Asphalt Melter Pour Pot with Wheels (OT001)

>> Vertical Machining Center Vmc 1160 Vmc855 1380