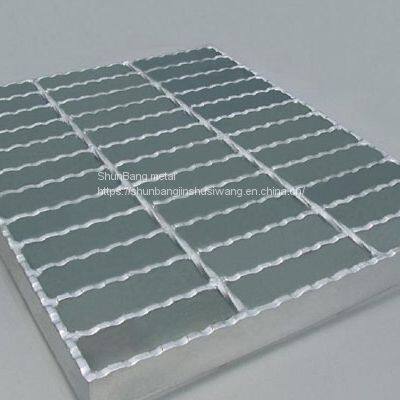

Anti skid ditch cover plate

Product Description

Product DescriptionThe steel grating trench cover plate adopts the trench (well) cover plate made of steel grating, and has a variety of models for selection to meet different span loads and requirements.

Steel grating trench cover plate material: 1. Flat steel: Q235A or stainless steel, with ordinary plane type, anti-skid tooth type and section I type.

2. Common specifications include 20 * 5, 25 * 5, 25 * 3, 32 * 5, 32 * 5, 40 * 5, 40 * 3, 50 * 5, 65 * 5, 75 * 6, 100 * 8, 100 * 10, etc.

3. Cross bar: round steel, twisted square steel, square steel or hexagonal steel made of Q235A or 304 stainless steel. The twisted square steel is made by drawing and twisting the square die in a circular arc. Its common specifications are 5 * 5, 6 * 6, 8 * 8mm, etc.

Characteristics of steel grating trench cover plate:

1. Beautiful appearance: simple lines, silver appearance, modern trend.

2. good drainage: the leakage area is 83.3%, more than twice that of cast iron.

3. Hot dip galvanizing: strong rust resistance, maintenance and replacement free.

4. Anti theft design: the cover and frame are hinged, anti-theft, safe and easy to open.

5. Save investment: large span, heavy load, lower than cast iron price and save the cost of theft or crushing replacement.

6. High strength: the strength and toughness are much higher than that of cast iron. It can be used in large-span and heavy load environments such as docks and airports.

7. Multiple specifications: meet the needs of different environments, loads, spans, sizes and shapes.

The steel grating trench cover plate has the advantages of simple construction, light weight, good bearing capacity, impact resistance, bending rather than bending, large drainage capacity, beautiful and durable after hot-dip galvanizing treatment, anti-corrosion and incomparable with cast iron cover plate. Hinge connection or hook connection is adopted for easy opening and anti-theft function.

Purpose of steel grating trench cover: it is used in municipal roads, garden facilities, residential quarters, schools, stadium pipes and other places.

Process of steel grating trench cover plate: according to different applications, our company can provide trench (well) cover plates of different specifications and models. The surface can be hot-dip galvanized, cold galvanized (electroplated) or untreated. Description of trench cover plate size selection:

1. The direction of the flat steel is the bearing (supporting) direction, and the length L of the flat steel shall be determined according to the width of the ditch (well) and the reserved gap;

2. The plate shall be arranged according to the length of the trench (well), and the standard plate width conforming to the processing modulus shall be 995mm, and the gap between the plates shall be 5mm;

3. The remaining part of the ditch (well) less than 1m long shall be measured by the number of models;

4. The type of steel grating plate shall be selected according to the width of trench (well) and bearing requirements.

5. It is recommended to select standard sizes for design and construction. Our company can design and manufacture various sizes or have other functions according to user requirements.

>> Chinese Furniture Basic Customization Stacking Interlocking Metal Theather Pulpit Auditorium Church Chair

>> Swimming Pool Water Treatment, Suspended Solids and Sand Removal, Quartz Sand Filters

>> Laboratory Test Sieve Shaker Sifter Stainless Steel Vibrating Sieving machine

>> High Quality Black Colour Oblong Light Weight Violin Hard Case for Sale

>> Wholesale Disposable Thicken New Material Nonwoven Shoe Cover

>> Q1332X3m Engine Conventional Horizontal Pipe Threading Lathe

>> popular design easy operation upvc profile casement window

>> Factory Driving Toys Baby Sliding Car/Good Quality Child Slide Car for Kids/Wholesale 4 Wheels Slide Outdoor Push Kid Car

>> 2 Tons Super Energy Saving Fuel Mini Bagger of Hydraulic Excavator for Sale

>> High-Performance Compact Plastic Injection Molding Machine for Bins

>> Disease Diagnosis Equipment Treatment Instruments Alzheimer's Disease Cure Surgical Machine Device

>> Designer Perfume 75m Women Eau De Parfum Long Lasting Exclusive Smell Cologne Spray High Quality Fast Ship

>> Creative Single Layer Student Stationery Pencil Case

>> Automatic Machinery Cleaning Intestines Sausage Production Line / Hog Casings Cleaning Machine For Sausage Casings

>> 180 Meters Drilling Machine Crawler Track Water Well Drilling Rigs for Sale

>> Perfect High Quality 2013 47m Concrete Boom Pump Truck for Sale

>> New Style Polo Shirt of High Quality of 2022 with Short Sleeves for Women

>> Aluminum Composite Panel Machine Production Line Aluminium Composite Panel Manufacturer

>> Ollital Open Type Two Roll Rubber Mixing Mill Machine

>> Dry Land Vegetable Field Hydraulic Lift Vertical Rotary Tiller

>> Microfiber Wet/Dry Mop Pad Resuable Microfiber Clothes Dust Mop Cleaning Clothes

>> Taijia ZC3-T concrete tester digital sclerometer price digital concrete test hammer digital rebound hammer

>> GOST Cast Iron Ht200 Brass Seated Wedge Gate Valve Z41t-10/16

>> Wholesale fleece hoodie New Design Long Sleeve Men's Pullover Winter Warm Velour Velvet Suede Hoodie for Men

>> Smart Office Luxury Executive Furniture Ergonomic Single Motor Laptop Study Computer Gaming Sit Stand Table Electric Height Adjustable Standing Desk

>> Domestic 10 Ton Wheat Flour Milling Mill Machine for Sale

>> 600MHz - 6GHz LTE/4G/5g Indoor Antenna with High Strong Magnetic Mount Rg174 Cable SMA

>> 5HP Portable Outboard Motor 2 Stroke 103cc Outboard Motor

>> 1bz-2.5 Disc Harrow (disc harrow) Heavy-Duty Disc Harrow

>> Customizable Floor Deck Rolling Forming Machine Tile Industry Floor Forming Machine