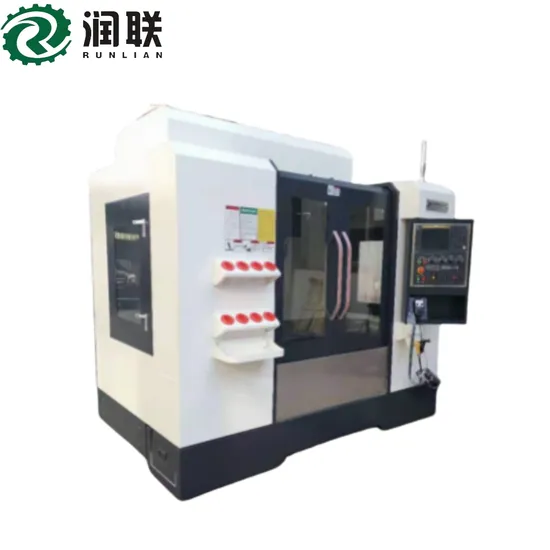

CNC Vertical Milling Machine Vmc750 Vertical Machining Center Low Price

Basic Info.

Model NO.

VMC750

Type

Worktable Milling Machine

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Inlaid Tooth

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

High Precision

Certification

CE

Condition

New

X/Y/Z Travel

700mm/450mm/500mm

Spindle Speed

10000rpm

Spindle Power

5.5/7.5kw

Spindle Taper

Bt40

Positioning Accuracy

0.003mm

Repeat Positioning Accuracy

0.0015mm

Table Size

900mm*500mm

Max. Table Loading

400kg

T Slot

5-14-90

Cutting Speed

1-10000mm/Min

X/Y/Z Rapid Speed

48/48/48 M/Min

Power

380V/220V/415V/50(60)Hz

Machine Net Weight

4.1t

Overall Dimension

2520mm*2200mm*2400mm

Transport Package

Wood Packaging

Trademark

OEM

Origin

China

HS Code

8457101000

Production Capacity

1000unit/Year

Packaging & Delivery

Package Size

300.00cm * 300.00cm * 300.00cm

Package Gross Weight

4500.000kg

Product Description

Product DescriptionCNC Vertical Milling Machine VMC750 Vertical Machining Center Low Price

VMC750 Vertical milling machine machining operations utilize vertical machining centers (VMCs), which, as the name suggests, have vertically oriented machine tools. These machines are primarily utilized to turn raw blocks of metal, such as aluminum or steel, into machined components.

VMC Series Machine Application

This machine is suitable for processing machinery and mold manufacturing field of vertical machining center, from the rough machining and finish machining and processing requirements apply, can finish milling, drilling, tapping, boring, and a variety of processes.

Vertical machining center Features

1- High-quality resin sand

2- Taiwan spindle

3- Taiwan ball screw and locking nut

4- Taiwan pressure cylinder

5- Automatic lubrication system

6- Chip conveyor at optional

Product Parameters

| Specifications | unit | VMC750 |

| X/Y/Z travel | mm | 700/450/500 |

| Distance from spindle nose to table surface | mm | 120-620 |

| Distance from spindle center to column surface | mm | 570 |

| Spindle Power | kw | 5.5/7.5 |

| Spindle speed | rpm | 10000 |

| Spindle Taper | BT40 (Φ120) | |

| Positioning Accuracy | mm | ±0.003 |

| Repeat Positioning Accuracy | mm | ±0.0015 |

| Table Size | mm | 900x500 |

| Max.Table loading | kg | 400 |

| T-Slot | 5-14-90 | |

| X/Y/Z rapid speed | M/min | 48/48/48 |

| Cutting Speed | mm/min | 1-10000 |

| X/Y/Z axes ball screw diameter | Φ32 | |

| X/Y/Z axes servo motor power | kw | 2.0/2.0/3.0 |

| Linear width X/Y/Z | mm | 35/35/35 |

| Guideway No. X/Y/Z | 2/2/2 | |

| Slider No. X/Y/Z | 4/4/4 | |

| Max.power consumption | kw | 11 |

| Air | Mpa | 0.5-0.7 |

| Power | 380V/220V/415V/50(60)Hz/3ph | |

| Ambient Temperature | 0ºC-42ºC | |

| Relative humidity | ≤80% | |

| Machine Net Weight | T | 4.1 |

| Overall Dimension | mm | 2520x2200x2400 |

| Working conditions 1- three-phase AC power supply: 380V ±10% ≤ 15%; 50Hz ±1Hz, main power wire 8mm or larger, ground wire 8mm or larger 2- ambient temperature: 8 - 40C ° 3- relative humidity: ≤ 80% 4- far away from the light source, vibration source, and heat source, away from high-frequency power generation motivation, discharge motivation, welding machine, etc., to avoid electrical interference caused by machine tool NC system failure | ||

Detailed Photos

Company Profile

Weifang Runlian Economic and Trade Co., Ltd. was established in 2011, Is a professional domestic high-end machine tool equipment And accessories import and export enterprise, metal cutting machine tools, metal cutting tools, Grinder abrasives, measuring tools, machine tool functional parts, numerical control devices, metal forming machine tools, lubricating grease, and oil Machine function parts, numerical control devices (CNC), Metal forming machine, mechanical processing technology consulting business, adhering to the core value of "customer satisfaction is our purpose", With the core cultural concept of "team, responsibility, communication, tolerance", Take advantage of nearly 20 years of industry experience to provide global customers with the most suitable industry products to create the greatest value, to become a world-class industrial service provider. FAQ

Q1: Are you a factory or a Trade Company?

A1: We are Industry and trade integration.

Q2: Is your company accept customization?

A2: Yes, we can undertake to customize and process, including non-standard products(We could make it according to your request.).

Q3: What is the Payment Term?

A3: FOB, CFR, and CIF are all acceptable.

Q4: When is the delivery time?

A4: A) The machine Tools & Accessories could be arranged for delivery within 3 days after your full payment,

B) The Machines Could Be arranged for delivery Within 20 -30 Days(Include Production Time).

Q5: What are the shipping ways?

A5: International express, by air, by sea are all ok.

>> Factory Custom Waterproof Children Pupil Primary Student Cute Girls Kids School Bag

>> 60kg-300kg Single Point Load Cell for Automatic Sorting Scale LC1535

>> Custom Color Cable Management Box for Desktop Storage Cable Organization

>> High Automation Machinery Waste Plastic Pet Bottle Recycling Melting Machine Washing Line

>> CNC Boring Machine (ZJA06-0606)

>> GREETMED surgical suture disposable polypropylene absorbable surgical suture thread

>> Black walnut main door with Double Sidelights Design /Doors Front Entry Glass with wrought iron Insert

>> Automatic Small Maker Making Machine Puff Snack Filling Machine

>> High Quality CNC Press Brake Tool, Press Brake Dies, Gooseneck Tool, Yawei Press Brake Tool, Amada Press Brake Punch, Wilson Bending Dies, Hemming Punch Tool

>> Bedroom Bedside Reading Wall Lamp Stylish Hotel Headboard Wall Light

>> China Excavator Manufacturer Small Bagger

>> Tilapia Feed Pellet making Machine

>> plastic packaging bags custom logo printed aluminum foil packaging bag

>> Floating Aquaculture Fish Cage Net PE

>> Automatic Cosmetic Bottle Filling Machine Toner Liquid Foundation Filling Machine Makeup Remover Bottle Filling Machine

>> Nanometer Materials High Lumen 150lm/W 1200mm 18W T8 Tube LED

>> Custom Optic Fiber MPO Pigtail MTP Fiber Array Assembly

>> One Step Semi Automatic Blow Molding Machine Pet Injection Stretch Blow Molding Machine

>> Stainless Steel Bimetallic Thermometer Back Mounting Temperature Gauge

>> BMI Body Composition Height Weight Scale Printing Supported BMI

>> End Mill Re-Sharpening Machine Grinder for Tungsten Carbide and High-Speed Steel

>> Economical inkjet date and batch printing machine face mask logo printer

>> Factory Customized Paper Pulp Tray Packaging Mould Manufacturing/Aluminum Paper Fruit /Apple Tray Mold

>> Excellent body kits for BMW X6 E71 body kit 2008-2014 X6/X6M to HM style body kits for BMW X6 middle muffler HM style

>> Taijia Hand-Held Non-Destructive Rebar Locator Instrument For Concrete Acceptance

>> Low Price Big Gear Ring Die Type Straw Pellet Line

>> Double Shaft Dust Humidification Mixer Crusher

>> Cameron 2 1/16 Inch Wkm Gate Valve

>> Motorcycle Spare Parts Wet Dry Gel Battery 6n4-2A

>> Comfortable Medical Use Anti-Fatigue,Insomnia Disorders Magnetic Field Therapy