Hoosun High-Speed Agitator Dissolver for Battery Ceramics Nanomaterials Coatings

| US$18,500.00-19,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

IMS 7

Application

Granules, Liquid, Liquid with Suspended Solids, Powder, Viscous Fluid

Application Area

Chemical

Certification

CE, ISO

Condition

New

Control System

Touch Screen Control

Main Material

Alloy Steel, Aluminum

Mixing Capacity

<50ml

Mixing Drum Shape

Circular Groove

Power Supply

Battery Operated

Safety Features

Anti-Slip Feet, Emergency Stop Button, Overload Protection, Safety Lock, Splash Guard

Special Features

LED Display

Speed Control

Single Speed

Speed Range

60 R/min & Above

Stirring Type

Forced

Temperature Control

With Cooling System

Type

Mixer Mill

Voltage

380V

Warranty

1 year

Working

High Speed Mixer

Power

200-250kw

Maximum Rotation Speed

3000 Rpm

Processing Volume

25000-40000 L

Powder Suction Speed

1000kg/Min

Maximum Viscosity

60 MPa.S

Liquid Flow Rate

180 M³/H

Suspension Flow Rate

2-4 M³/H

Layout Type

Horizontal

Operating Type

Cycle Operating

Mixer Type

Laboratory Inline Mixer

Transport Package

to Order of The Customer

Specification

To order

Trademark

Hoosun

Origin

Shanghai, China

HS Code

84798990

Production Capacity

1000 Pieces/Year

Product Description

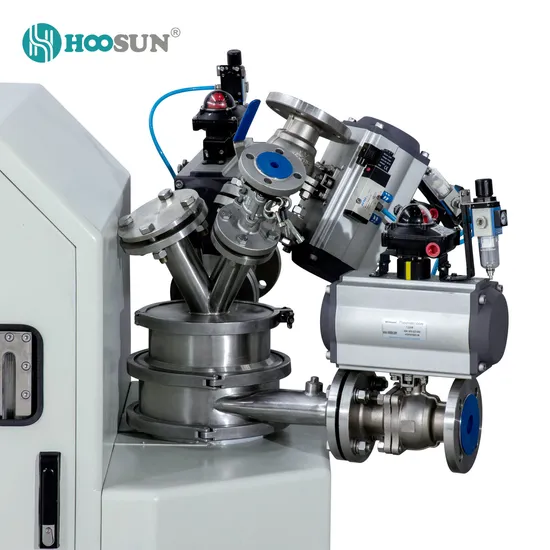

Product Description: Product Description: The IMS1 Continuous Dispersing and Mixing Equipment utilizes the Venturi effect for efficient and precise mixing and dispersion of liquids with suspended solids, powders, viscous fluids, and granules. Designed for laboratory applications, this high-speed inline mixer is ideal for chemical industries, coatings, dyes, pigments, and more.Application Areas:

Micro and nano materials Ceramic materials Battery homogenization Conductive materials Digital inkjet Coatings and inks Key Features and Benefits:

High Efficiency: The IMS1 provides high-speed mixing and dispersion, achieving uniform particle size distribution and material homogeneity. Energy Efficiency: Advanced vacuum dispersion technology reduces energy consumption by more than 70%, leading to significant cost savings. Automation and Ease of Use: Easily integrates into automated systems, ensuring stable and reliable operation with minimal operator involvement. Durability and Reliability: Constructed with high-quality materials, ensuring long service life and stable operation. Versatile Applications: Suitable for a wide range of materials and processes, from chemical industries to digital printing. Technical Specifications:

Power (kW): 200-250 Maximum Rotation Speed (rpm): 3000 Processing Volume (L):25000-40000 Powder Suction Speed (kg/min): >1000 Maximum Viscosity (mPa.s): 80 Liquid Flow Rate (m³/h): 180 Suspension Flow Rate (m³/h): 3-20 Unique Technologies:

Special stator-rotor design ensures high-speed shear slurry and uniform particle distribution. Vacuum powder suction without loss and closed chamber to prevent leaks and contamination. Savings and Efficiency:

Energy-saving technologies reduce production and operational costs. High dispersion efficiency ensures superior product quality. After-Sales Service:

Professional installation and commissioning. Lifetime technical support and maintenance. Conclusion: The IMS1 is a reliable and highly efficient solution for mixing and dispersion in various laboratory applications. Its advanced technologies, energy efficiency, and ease of use make it an indispensable tool for your production needs. Contact us for more information and to place an order!

Technical Specifications Table for IMS Models:

| IMS1 | 3 | 8000 | 20-500 | 1-4 | 60 | 10-20 | 2-4 |

| IMS2 | 3-7.5 | 6000 | 100-200 | 4-12 | 100 | 15-30 | 5-10 |

| IMS3 | 11-18.5 | 4000 | 200-1500 | 6-20 | 200 | 20-30 | 10-20 |

| IMS4 | 22-37 | 3000 | 1500-8000 | 3-10 | 100000 | 30-50 | 30-50 |

| IMS5 | 45-90 | 3000 | 8000-15000 | 10-30 | 100000 | >80 | 40-60 |

| IMS-Plus | 75-110 | 1950 | 8000-15000 | >100 | 100000 | >100 | 50-80 |

| IMS6 | 110-160 | 3000 | 15000-25000 | 1-5 | 300000 | 50-80 | 60-100 |

| IMS7 | 200-250 | 3000 | 25000-40000 | 5-30 | 300000 | 60-100 | 60-100 |

Company Profile

Exhibition

CE & ISO certification Signing Ceremony & After-sales service

Our Customers FAQ

>> Multi-Leg Polyester Webbing Round Sling Rigging Assembly

>> 10 Gallon Compact Foldable Decorative Outdoor Theme Park Garbage Can Plastic Injection Molding Machine

>> infusion sets disposable blood infusion set with filter for blood transfusion

>> Modern Round Pink Injection Wall Mirror Decoration Living Room Geometric Glass Decorative Simple Wall Mirrors

>> 4G Dual Lights PT Outdoor Camera Human Detection Solar Battery CCTV Camera Outdoor Home ATM Office WiFi 4G PIR Security Camera

>> Gtop Series Intelligent Illumination Seed Germination Incubator

>> Hot sale and best quality 5L PET stretch blow molding machine machinery

>> Cardboard Recycling Machine/Carton Shredder/Cardboard Shredder

>> Industrial Kitchen Equipment 10lx2 Commercial Freestanding Electric Split Tank Turkey Chips Chicken Deep Fryer, 2 Tank 2 Basket, CE Approved (DF-10L-2)

>> Hepatic disease and colon disease detection Non-invasive and radiationless medical examination

>> High Precision Ss Knife Edge Grinding Sharpening Machine with CE

>> Easy to Use and Maintain Powerful Air Supply Oscillating Electric Portable Air Circulating Fan

>> 11CH 2.4G 4WD Remote Control Drive Dump Truck RC Car with Light and Music

>> UT100 Multifunctional PP nonwoven shopping bag Ultrasonic Sewing Machine, medical surgical dress ultrasound bonding equipment

>> fractional co2 laser price/vaginal tightening co2 fractional laser device

>> 6-18 M Mobile Electric Lifting Platform Self Propelled Man Lift Electric Scissor Manlift

>> Automatic Barrier Gate for Car Parking and Highway Toll System

>> Glow in The Dark Pigment Blue Powder for Resin Verify Glow in The Dark Acrylic Powder

>> Precision Fanuc CNC 5 Axis Milling Machine GF-2214 Gantry Type CNC Machining Center

>> Bridgeport Milling Machine Made in China

>> HONEYWELL CC-PAIM01 C300 controller

>> Custom Pink Organic Cotton Cleaning Pad Reusable Washable Makeup Remover Pad

>> 5.8GHz/2.4GHz Dual-Band Signal Booster for WiFi, Fpv or Dji Drone Signal Extender

>> Corn Grain Cereal Powder Crushing Grinder Machine Wheat Flour Mill Maize Milling

>> CURREN 8386 Waterproof Quartz Montre Homme Business Fashion Titanium Belt Watch

>> High-Efficiency Concrete Pump for Construction Projects and More

>> Portable Ice Rink Fence Quick Ice System HDPE Polyethylene Dasher Board

>> 1ton-10ton Waste PVC Pipe Crusher Plastic Tube Grinding Mach Fast Crusher Machine

>> Platform step heavy plug-in steel grating grating composite hot-dip galvanized toothed steel grating

>> Good Quality Pet Capsule Injection Machine / Plastic Cap Making Machinery