Nai-Lok Hc-276 5000psi Double Ended 1/4 Female NPT Sample Cylinder 1000ml 500ml 300ml 150ml Sampling Cylinder with PTFE Coating

| US$158.00 | 5 Pieces (MOQ) |

Basic Info.

Model NO.

Sample Cylinder

Function

Separation Pressure Vessel

Application

Liquefied Gas

Material

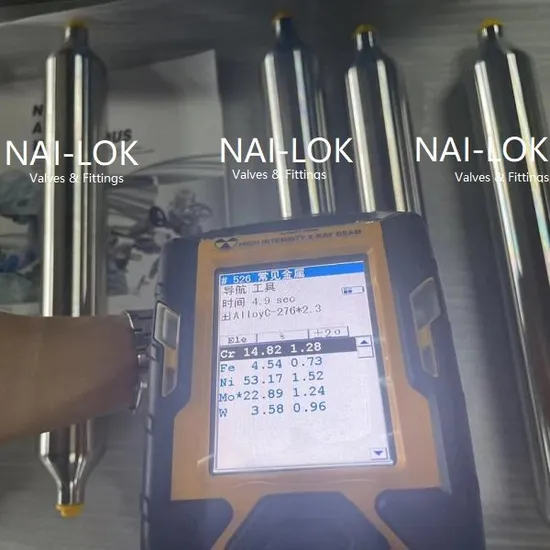

Alloy / Stainless Steel

Pressure

10.0MPa≤p<100.0MPa

Storage Medium

Highly Toxic

Pressure Level

Ultra High Pressure (p≥100.0MPa)

Condition

New

MOQ

5 PCS

Connection

Double Ended

Body

Stainless Steel / Inconel / Hastelloy / Monel

Sample Vessel

Sample Cylinder or Glass Bottles

Working Pressure

1800psi / 3000psi /5000psi

Capacity

150ml/300ml/500ml/1000ml/1gal

End

1/4 Female NPT

Standard

DOT

Transport Package

Wooden Case

Specification

1/4 / 1/2

Trademark

NAI LOK/OEM

Origin

China

HS Code

7304419000

Production Capacity

10000meter/Month

Product Description

Nai-Lok HC-276 5000psi Double Ended 1/4 Female NPT Sample Cylinder 1000ml 500ml 300ml 150ml Sampling Cylinder with PTFE CoatingOil and Gas Stainless Steel Instrument Sampling Container Cylinder with Rupture Disc Needle Valve

Pressure Vessel for Sample System Seamless Gas Sample Containers Gas Bottle

Treatment: Vulcanization Coating, Sulfur Passivation Coating

Volume/Capacity:150ml,300ml,500ml,1000ml,1500ml,2000ml,1Gal

Sample CylindersFeatures* Working pressure up to 5000 psig (344 bar),20Mpa* Internal volume from 40 to 3785 cm³* double-ended 1/4 or 1/2 Female NPT * Seamless tubing body provides consistent wall thickness, size and capacity* Heavey wall end connections provide strength and resist flaring* 316L 904L and alloy 625 / HC276 /HC22 and alloy 400 stainless steel materials available

| Materials Grade/Cylinder Specification | Working pressure, psig (bar) | Internal Volume cm³± 5% | P-Female NPT | Dimension,in.(mm) | |||

| D | L | Minimum wall thickness | Weight lb(kg) | ||||

| Double-Ended | |||||||

| 316L S.S | 1800(124) | 150 | 1/4 or 1/2 | 2.00(50.8) | 5.25(133) | 0.093(2.4) | 0.94(0.43) |

| 300 | 8.94(227) | 1.80(0.82) | |||||

| 500 | 13.8(351) | 2.60(1.20) | |||||

| 316L S.S | 3000(344) | 150 | 1/4 or 1/2 | 1.90(48.2) | 8.00(203) | 0.240(6.1) | 3.00(1.40) |

| 300 | 14.5(368) | 5.60(2.50) | |||||

| 500 | 23.5(597) | 9.10(4.10) | |||||

| Alloy 400/625 HC276 HC22/904L | 1800(124) | 150 | 1/4 or 1/2 | 2.00(50.8) | 5.25(133) | 0.093(2.4) | 0.94(0.43) |

| 300 | 8.94(227) | 1.80(0.82) | |||||

| 500 | 13.8(351) | 2.90(1.3) | |||||

Custom design services are available! User shall provide effective on-site sampling media pressure, temperature, type of media and specific on-site sampling environment for us. Sampling Systems Points designs and manufactures by ourself, assemble many spare parts of liquid samplers, Sample Cylinder, and sample coolers, valves, tube fitting, flange and do on. These systems collect toxic or volatile organic chemicals and process streams, and prevent the escape of emissions into the atmosphere. This is a new non-leaking, pollution free sampler which is used for sampling all kinds of toxic, corrosive, explosive and flammable samples from petrochemical process pipe.

Our Sampling System Units performs these tasks obtaining representative and contamination-free samples safely. All sampling systems whether gas samplers, liquid samplers, or custom samplers, can be made to operate manually or automatically and are designed to meet hazardous area classifications if applicable.

Custom design services are available! We can also design and manufacture sealed sampling device to meet your special technical and safety requirements.

Sampling Systems offers many different liquid sampler options for collecting liquid samples. These units allow the user to collect samples from a wide range of applications, from high pressure to low pressure, and various different temperature ranges. Many of the options can be modified to operate automatically.

>> Anti Theft Home Hotel Safety Device Door Stop Alarm

>> Hpm-125 Semi-Automatic Horizontal Non-Metal Baler Is Easy to Add Material

>> DI524 DI581-S DI610 DI620 DI651 ABB AC500 PLC switching value input module

>> Polo Shirt T-Shirt Placket Pocket Laser Opening Sewing Machine

>> Carbon Steel Zinc Fine Thread Course Thread DIN18182 Drywall Screw

>> Electric Pulse Foot Massage Acupuncture Pad EMS Foot Massager Mat

>> Motor Blade Water Pump Plastic Fan Impeller

>> Japanese cheap room fold screen partition movable bamboo rattan woven restaurant living room divider home garden doors decor

>> Bestchickencage Manure Drying Machine China Cow Dung Dewatering Machine Manufacturing Wholesale High-Strength Screw Shaft Low Price Manure Dryer

>> automatic buddha incense making machine incense stick machine

>> Pfs3010-8et-65 10 Port Fast Ethernet Switch 8 Port Poe Dahua Poe Watchdog with 250 M Long Distance Poe Transmission

>> Best Sale Space Capsule Zero Gravity Full Body SL Track Electric Luxury Shiatsu Massage Chair

>> Auto PC Slab Making Machine Precast Concrete Tile Slab Making Machine Concrete Floor Tile Making Machine Baldosa De Concreto

>> Multi-Layers 200L-2000L Tank Blow Moulding Machine

>> COMFLIVE Cotton Body Medium Support Pillow-Gray

>> Powerful Chip Removal Oil Groove Side Oblique End Milling Cutter for High Temperature Alloy Cutting

>> Electric Tomato Picker Agriculture Harvest Trolley

>> New Design Safety Caution LED Waterproof Barricade Flashing Solar Signal Traffic Road Warning Light for Construction

>> Horizontal Manual Gear Head Mini Gap Bed Metal Lathe Machine

>> FACTORY SELL 6CT oil seal seat gasket 3933384 4205010 3913447 3938043 4205010 3926126

>> PP Honeycomb Sheet Pallet Sleeve Box for Home Appliances Industry

>> Customized 30′ ′ Carbon Detachable Handle Ice Fishing Rod

>> 1000PCS/Roll Square 40*40mm 50*50mm Bar Code Printable 8.2 MHz RF Security Tags EAS Anti Theft Stickers for Retail Stores

>> Customized High Precision Hardware Part

>> 20kHz 2000W Ultrasonic Welding Machine Piezoelectric Ultrasonic Generator Welding System

>> Pet Blowing Machine Including Blower

>> Factory Wholesale Price Aluminum Bottle Cap 4 Color Offset Printing Punching Machine Aluminum Cap Machine Bottles Caps Machines

>> Body Kit For Benz E Class W213 modified E63S Amg style Front car bumpers with grill

>> High Quality Steel Trailer Wheel Rim for 22.5X11.75

>> Extruder Fish Feed Pedigree Dog Food Making Dog Dry Food Packaging Machine