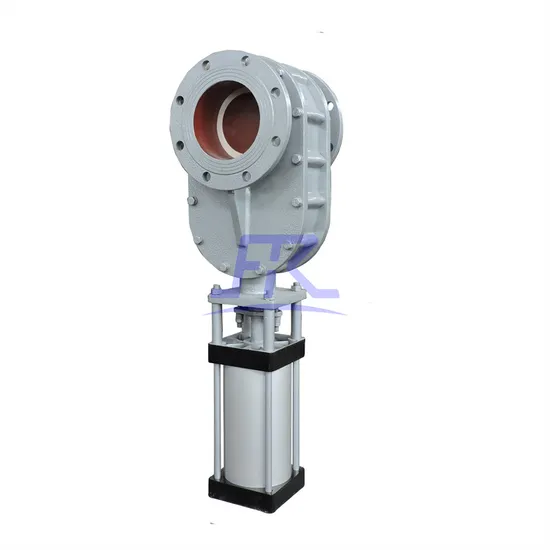

Industrial Valve Frz644tc Pneumatic Flanged Ceramic Lined Double Disc Balance Gate Valve

| US$500.00-6,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

FRZ644TC

Type

Straight-through

Material

Ceramic

Connection Form

Flange

Pressure

Ordinary Pressure

Actuator

Pneumatic

Seal Surface

Parallel Gate Valve

Thread Position of Valve Rod

Outside Gate Valve

Usage

Drain, Flow Control

Standard

DIN

Application

Industrial Usage

Face to Face

Size Can Be Customized

Color

Colors Can Be Customized

Air Pipe Size

8,10

Position Feedback

Magnetic Position Switch or Mechanical Limit Switc

Transport Package

Wooden Box

Specification

DN50-DN350

Trademark

FREE-VALVE

Origin

China

HS Code

8481804090

Production Capacity

200 Set/Month

Packaging & Delivery

Package Size

600.00cm * 600.00cm * 450.00cm

Package Gross Weight

80.000kg

Product Description

Product DescriptionFREE-VALVE Pneumatic Flanged Ceramic Lined Double Disc Balance Gate Valve is mainly used in feeding and dumping the dry powder and the transport pipeline, which not only adopt toughening ceramic as shut off and wear out resistance material, but also design construction of pressure self-sealing and valve disc auto-rotate, so as to the sealing surface within the dry powder get more wear resistance in process of opening and closing frequently, thereby, which guarantee the high requirements of sealing performance of this valve and long working time.

Features

1. Sealing pair is made of structural ceramics,which have perfect performance to resist wear and flushing.

2. Two-side sealing can realized due to double disc structure of the pneumatic ceramic double disc gate valve.

3. It inserts spring between double valve discs to ensure self- sealing through bi-directional flexible preload pressure of spring, having characteristics of low pressure bi-directional sealing and without dust clogging phenomenon in the process of the opening and closing of valve.

4. The valve disc rotational motion can avoid the ash deposition on the sealing surface during opening and closing, so the valves have much longer service.

5. The blow sweep port or automatic blow sweep device can be set on the valve body according to different operating conditions.

Technical Specification

| 1 | Size Range | NPS2~NPS14,DN50~DN350 |

| 2 | Nominal pressure | Class 150 /PN10/PN16 |

| 3 | Applicable Temperature | 0~200ºC |

| 4 | Connection Type | Flange |

| 5 | Disc | Carbon steel+ceramic,stainless steel+ceramic |

| 6 | Seat | ceramic |

| 7 | Pressure test | Pressure test |

| 8 | Face to Face | GB/T12221, ASME B16.10 |

| 9 | Flange standards | ASME B16.5,GB/T9113 |

| 10 | Operating Type | Pneumatic |

| DN | PN | L | D | D1 | D2 | n-∅d |

| DN50 | PN10 | 240 | 160 | 125 | 99 | 4-∅18 |

| DN65 | PN10 | 260 | 180 | 145 | 118 | 4-∅18 |

| DN80 | PN10 | 260 | 200 | 160 | 132 | 8-∅18 |

| DN100 | PN10 | 280 | 220 | 180 | 156 | 8-∅18 |

| DN125 | PN10 | 300 | 250 | 210 | 186 | 8-∅18 |

| DN150 | PN10 | 300 | 285 | 240 | 210 | 8-∅22 |

| DN200 | PN10 | 310 | 340 | 295 | 266 | 8-∅22 |

| DN250 | PN10 | 365 | 395 | 350 | 320 | 12-∅22 |

| DN300 | PN10 | 400 | 440 | 400 | 370 | 12-∅22 |

Note:Face to Face dimension "L" can be customized according to customer requirements

Application

1. Power plant ash handling system.

2. Cement industry-dry powder conveying and dumping.

3. Dressing works-dry powder materials' selection and conveying.

>> Kingball Detail-Oriented Jiangsu Famous Trademark Nc/CNC Press Brake Turkey/Durma Press Brake

>> Air Conditioner Tube/PE Foam Pipe/Foaming Insulation Pipe Extruder Machine

>> Sim5216E Multi-Band HSDPA/WCDMA/GSM/GPRS/EDGE 3G module

>> Hot Selling Titanium Mandrel Bending 90 Degree Mandrel Bends

>> Small Dog Food Extruder Machine Dog Food Processing Machine

>> BS-460GB Middle-Sized Auto Metal Cutting Miter Band Saw Machine with PLC, Band Sawing Machine

>> Customized High Transmission Pleated/Folding Mesh Trackless Sliding Aluminum Screen Door

>> Automatic Hydraulic Disposable Cardboard Paper Plate Molding Making Machine

>> Cotton Tape Webbing

>> China Aluminum Profile Supplier V-Slot Aluminum Profile Ob 20X20 Extrusion Industrial Aluminium

>> Good Selling Portable Clothes Hanger And Clothes Shelf indoor product

>> Factory Wholesale Price 7 Inch LCD Photo Frame Digital Electronic Picture Frame

>> S11 1109110 Car air filter housing Car air filter black casing for s11 chery qq

>> Tiktok Recommended 100% Polyester Winch Strap with Good Quality

>> 84559052 High quality front bumper FOR CHEVROLET MALIBU 2019

>> Llantas PARA Autos Passenger Car Wheel Rim Tires 13 14 15 16 17 18 19 20 22 24 Inch Tires Manufacture′s in China

>> Intelligent Shoe Upper Cloth Line Drawing Machine

>> Medical CE co2 fractional laser korea arm/co2 laser beauty equipment/Laser+Beauty+Equipment

>> Yhdc PE3018-M 2va Ei30 Series PCB Mounting Type Power Transformer

>> 15.6 Inch Intel N95 12th Gen Core I3 I5 I7 10th 11th 12th Gen Business Office Gaming Laptop Computer RAM 16GB Portable Win 11 in Stock Factory Price Laptops

>> Powder Coated Commercial Single Burner Gas Stove

>> 2024 Hot Sale Lotion Pump Lotion Dispenser for Cosmetic Bottle

>> EP5 transformer bobbins EP5 SMD (3+3P)Bobbins,EP5 transformer Accessories,PM9630 material with good high temperature resistance.

>> 78%Nylon 22% Spandex Fabric Sport Shirt Fabric

>> Promotion Folding PP Lamination Image Non Woven Tote Bag

>> Non Woven Fabric wholesale 3ply black face masks disposable protective mask

>> Custom Eco Friendly Biodegradable Luxury 5 Star Hotel Guest Disposable Amenities Toiletries Set Manufacturers

>> Classroom Interactive Board with Smart Features and Protection

>> China Pallet Manufacture Euro Virgin HDPE Injection Recycled Pallet Plastic Shipping Pallet Warehouse Storage Pallet

>> Dual Purpose Sofa Bed Foldable Small Family Double Three Person Study Lunch Break Sofa Folding Bed Storage Sofa Bed