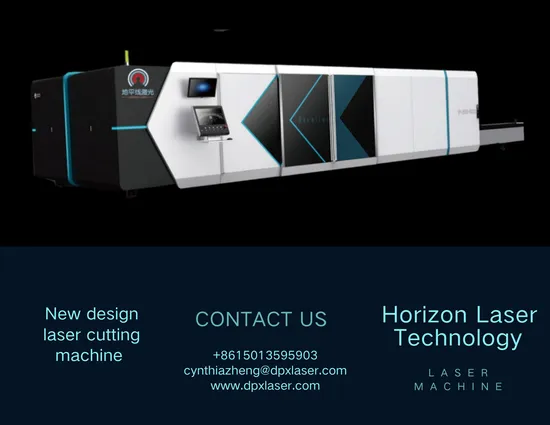

Cutter New 2024 Machine Laser Cutting CNC with Good Price Dpx-J3015

Basic Info.

Model NO.

DPX-J3015

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Advertising Industry

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Fiber Laser

Laser Technology

Laser Flame Cutting

Dimension

7800*2350*1900mm

Gross Weight

5t

Cutting Range

3000*1500mm

Laser Source

Max Ipg Raycus

Transport Package

Wooden Case

Specification

3015 cutting range

Trademark

Horizon Laser

Origin

China

HS Code

9013200010

Production Capacity

100PCS/Year

Packaging & Delivery

Package Size

7800.00cm * 2350.00cm * 1900.00cm

Package Gross Weight

5000.000kg

Product Description

Product DescriptionExchange table laser cutting machine comes with high processing efficiency. It adopts imported servo double-drive rack and pinion structure, parallel interactive worktables, and fully enclosed sheet metal outer protection. It is a laser cutting machine with superior performance and high-efficiency processing. Suitable for external processing or exclusive industry customer groups (aluminum sheet).

Detailed Photos

Product Parameters

Features One-click platform exchange, saving time and energy.

Double table design, cutting and loading & unloading can be carried out at the same time, ensuring uninterrupted processing all day long.

Full-enclosed protection and segmented follow-up dust removal design create a clean and friendly processing environment.

The high-strength bed combined with high-precision dynamic performance is specially designed for high-speed batch cutting of medium and thin plates.

High-power (12000W-30000W)

Technical Parameters

| Laser power | 12000-30000W | |||

| Model | DPX-J6025 | DPX-J8025 | DPX-J10025 | DPX-J12025 |

| Cutting range | 6000 × 2500mm | 8000 × 2500mm | 10000 × 2500mm | 12000 × 2500mm |

| Cutting focus method | Auto focus | |||

| Machine running accuracy | Acceleration: 1.8G | |||

| Maximum speed: 150m/min | ||||

| Axial positioning accuracy of worktable: ± 0.05mm/m | ||||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | ||||

Cutting Performance

| material | 12000W cutting performance | 15000W cutting performance | 20000W cutting performance | |||

| carbon steel | stable cutting | ≤ 35mm | stable cutting | ≤ 40mm | stable cutting | ≤ 45mm |

| Limit cut | 50mm | Limit cut | 60mm | Limit cut | 70mm | |

| Stainless steel | stable cutting | ≤ 30mm | stable cutting | ≤ 35mm | stable cutting | ≤ 40mm |

| Limit cut | 50mm | Limit cut | 70mm | Limit cut | 80mm | |

Application Effect

Medium power (3000W-6000W)

Technical Parameters

| Laser power | 3000-6000W | |||

| Model | DPX-J3015 | DPX-J4020 | DPX-J6025 | DPX-J8025 |

| Cutting range | 3000 × 1500mm | 4000 × 2000mm | 6000 × 2500mm | 8000 × 2500mm |

| Cutting focus method | Auto focus | |||

| Machine running accuracy | Acceleration: 1.2G | |||

| Maximum speed: 100m/min | ||||

| Axial positioning accuracy of worktable: ± 0.05mm/m | ||||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | ||||

Cutting Performance

| material | 3000W cutting performance | 4000W cutting performance | 6000W cutting performance | |||

| carbon steel | stable cutting | ≤ 20mm | stable cutting | ≤ 22mm | stable cutting | ≤ 25mm |

| Limit cut | 25mm | Limit cut | 25mm | Limit cut | 30mm | |

| Stainless steel | stable cutting | ≤ 9mm | stable cutting | ≤ 10mm | stable cutting | ≤ 14mm |

| Limit cut | 12mm | Limit cut | 14mm | Limit cut | 20mm | |

Application Effect

Low power ( 1000-2000W )

Technical Parameters

| Laser power | 1000-2000W | ||

| Model | DPX-J3015 | DPX-J4020 | DPX-J6025 |

| Cutting range | 3000 × 1500mm | 4000 × 2000mm | 6000 × 2500mm |

| Cutting and focusing method | Manual / automatic focusing | ||

| Machine running accuracy | Acceleration: 1.0G | ||

| Maximum speed: 80m/min | |||

| Axial positioning accuracy of worktable: ± 0.05mm/m | |||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | |||

Cutting Performance

| Material | 1000W cutting performance | 1500W cutting performance | 2000W cutting performance | |||

| Carbon steel | stable cutting | ≤ 8mm | stable cutting | ≤ 12mm | stable cutting | ≤ 16mm |

| Limit cut | 12mm | Limit cut | 16mm | Limit cut | 20mm | |

| Stainless steel | stable cutting | ≤ 4mm | stable cutting | ≤ 6mm | stable cutting | ≤ 7mm |

| Limit cut | 6mm | Limit cut | 8mm | Limit cut | 10mm | |

Application Effect

Certifications

Our Advantages

After Sales Service

1. 7*24 hour2. Response time<12 hours3.Online support4.Product replacement5. Customer field service6. Backup products during repairing for long time cooperators* International warranty ONLY valid if products are purchased directly from Horizon Laser or authorized local distributors/agents.

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

>> DHL Freight Forwarder Courier Air Express Shipping Dropshopping Delivery Door to Door Service to Poland

>> X1LG Self-Generator LED Mini Head High Speed Handpiece Turbine CE

>> Hollow Block Making Machine Qt4-40 Manual Interlocking Brick Making Machine

>> 500 Yards Curling Ribbon-Balloon String for Art&Craft Decoration

>> Vacuum Diamond Hole Saw

>> Frozen Vegetable California Mixed Vegetables with Carrot, Corn, Peas, Green Beans

>> Factory Direct Sale Plowing and Rotating Machine

>> High-Performance Yonge Yz08 DC Motor for Industrial Applications

>> Hot Sale Single Wall Disposable Custom Paper Cup Making Machine for Hot Drinks

>> Paper Cup Pad Making Printing Machine

>> Stainless Steel Safety Traffic Island Bollards

>> Clear/Coloreded/Insulating/Sheet/Tempered/Laminated Glass for Building Glass

>> Three Axies 250CNC Precision Machine Tool for Grinding and Milling Tasks

>> Reputable Crusher Spare Parts Supplier with Guaranteed Quality and Adaptable to Various Crushers /OEM 485.0091-001

>> High Capacity Petrol/Diesel Engine Tilting Drum Concrete Mixer (400L)

>> Taijia ultrasonic test crack depth and defect detection upv test ZBL-U5200 ultrasonic flaw detector

>> Stage Decor DJ Controller LED Strip Pixel Bar SMD5050 DMX RGB LED Linear Bar Light DMX Programmer Aluminum LED Pixel Tube

>> Customized Eco Foldable Extra Large Heavy Big Thick Capacity Casual Cotton Canvas Shopping Tote Bag Oversized Canvas Cotton Bag

>> Double Direction Crushing Auto Pre Mixer

>> Dried Mushroom Edible Fungus Boletus Edulis Porcini

>> Japan custom wooden cherry kitchen wall cabinet with glass doors

>> Automatic Steel Purlin Roll Forming Machine for Glazed Tiles for Wall Gutter Building Construction PLC Control New Ibr Sheet

>> HC-M125 hospital/Lab supplies portable Stainless steel test tube rack and holder (18/30/40/60)

>> Universal Milling Machine Horizontal Lifting Table Milling Machine

>> Garment Printer Impresora Dtf T Shirt Manufacturer A3 Roll 5 Heads Dtf Printer Printing Machine

>> Zx7550z Metal Gear Head Vertical and Horizontal Drilling Milling Machine

>> Indulge in Grounding Pillowcase: Deep Sleep Inducer, Energy Amplifier & Inflammation Calmer

>> Semi-Auto Stretch Blow Moulding Machine 4cavity

>> Unrivaled Accuracy of Precision-Crafted High-Voltage Relay Helium Leak Testing Machine

>> Biomass Pyrolysis Equipment Carbonization Furnace Is Used for Wood Sawdust Carbonization Furnace