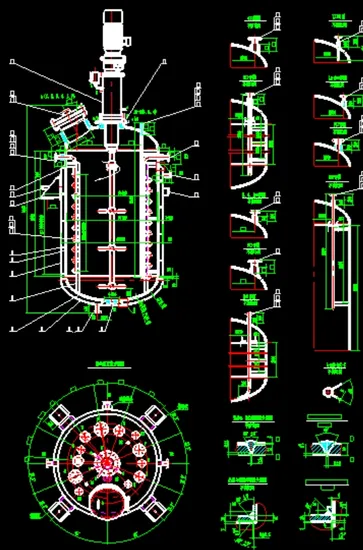

6700L Magnetic Coupling Stirring Hydrogenation Kettle Amino Compounds, Hydrogen Gas Pressure Vessel Stainless Steel Chemical Reactor

| US$38,000.00-42,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

FCHA

Type

Reaction Kettle

Material

S31603, Q345r

Capacity

6.7m³

Structure

Jacket and Coil Tube

Pressure

Positive

Heating

Heat Transfer Oil, Steam, Water, Ethylene Glycol

Heat Transfer Structure

Jacket and Coil Tube

Automatic Grade

Automatic

Condition

New

Rotation Speed

0-299r/Min

Power

30.0kw

Seal Type

Magnetic Seal Zero Leakage

Total Weight

8053

Lead Time

90 Days

Branch Office

California, USA

ODM

Available

OEM

Available

Specification

6.7m³

Trademark

LUHAO

Origin

China

HS Code

84198990

Product Description

Vessel Capacity m³: 6.7 Material: S31603+Q345R Design pressure MPa: 3.5 Design temperature ºC: 150 Work pressure MPa: 2.5 Work temperature ºC: 120 Medium: Amino compounds, hydrogen gas Working life: 10 years Jacket Capacity m³: 0.9 Material: Q345R Design pressure MPa: 0.8 Design temperature ºC: 150 Work pressure MPa: 0.6 Work temperature ºC: 140 Medium: Heat transfer oil, steam Heat exchange area m2: 14.8Coil tube Capacity m³: 0.08 Material: S31603 Design pressure MPa: 0.6 Design temperature ºC: 150 Work pressure MPa: 0.5 Work temperature ºC: 130 Medium: water, Ethylene glycol aqueous solution Heat exchange area m2: 8 Total weight Kg: 8053 *For confidential reason, the drawing is in low definition. Please contact us for more information.

| MODEL | FCHA1000-2000L | FCHA3000-5000L | FCHA6000-8000L | FCHA10000-15000L | FCHA15000-25000L |

| CAPACITY | 1000-2000L | 3000-5000L | 6000-8000L | 10000-1 5000L | 15000-25000L |

| WORK PRESSURE MPa | -0.1-10.0 | -0.1-10.0 | -0.1-10.0 | -0.1-10.0 | -0.1 -8.0 |

| WORK TEMPERATURE C° | -15-320 | -15-320 | -15-320 | -15-320 | -15-320 |

| rpm | 0-320 | 0-320 | 0-320 | 0-320 | 0-320 |

| DC motor power W | 3.0-11.0 | 11.0-22.0 | 15-37.0 | 22.0-55.0 | 37.0-75.0 |

| Main materials | 09MnNiDR/16MnDR (low-temperature steel), 15CrMoR (high-temperature steel), stainless steel S30408/S32168/S31603, S39042, titanium material, duplex steel, shackle material, Hastelloy alloy, zirconium material, Monel, and other materials used for explosive composite plates. | ||||

| Heating form | Jacket thermal oil, jacket steam, outer half pipe, inner coil pipe; Electric heating/flue gas heating (435ºC). | ||||

| Mixing form | Disc turbine type, asymmetric turbine type, three blade impeller type, disc inclined blade, four wide blade, propulsion type, impeller type, anchor type, frame type, screw belt type, etc. | ||||

| Shaft sealing form | Magnetic coupling drive with static sealing, zero leakage, long service life, simple installation, safe and environmentally friendly. | ||||

| Remarks | Other special requirements, touch screen intelligent control, program control, and connection to DCS systems shall be designed, manufactured, and configured according to user needs. | ||||

| LUHAO Chemical Machinery Co. Ltd | ||||||||||||||

| Pressure Vessel Design Information Collection Table | ||||||||||||||

| Vessel | Jacket (Coil) | |||||||||||||

| Work Medium | Name | |||||||||||||

| Components | ||||||||||||||

| Density (Kg/m³) | ||||||||||||||

| Characteristics | ||||||||||||||

| Viscosity (cP) | ||||||||||||||

| Flow Velocity(m³/h) | ||||||||||||||

| Design pressure (Mpa) | ||||||||||||||

| Work pressure (Mpa) | ||||||||||||||

| Design temperature(ºC) | ||||||||||||||

| Work temperature (ºC) | ||||||||||||||

| Wall temperature (ºC) | ||||||||||||||

| Diamter (mm) | ||||||||||||||

| Length (mm) | ||||||||||||||

| Capacity(m³) | ||||||||||||||

| Effective capacity (m³) | ||||||||||||||

| Corrosion allowance (mm) | ||||||||||||||

| Corrosion speed (mm/year) | ||||||||||||||

| Recommended Materials | ||||||||||||||

| Lowest value of average monthly temperature(ºC) | ||||||||||||||

| Site location | ||||||||||||||

| Installation condition | Indoor Outdoor | |||||||||||||

| Catalyst Volume(m³) | ||||||||||||||

| Catalyst Density(Kg/m³) | ||||||||||||||

| Heat Transfer Area() | ||||||||||||||

| Coil Specification | ||||||||||||||

| Basic Wind Pressure(Mpa) | ||||||||||||||

| Seismic Basic Intensity | ||||||||||||||

| Ambient Temperature(ºC) | ||||||||||||||

| Site Type | ||||||||||||||

| Operating Mode | ||||||||||||||

| Insulation Materials | Name | |||||||||||||

| Thickness | ||||||||||||||

| Density (Kg/m³) | ||||||||||||||

| Seal Requirements | ||||||||||||||

| Liquid Level Gauge | ||||||||||||||

| Emergency Cut-off | ||||||||||||||

| Static Electricity Removal | ||||||||||||||

| Anti Eddy Current Requirement for Liquid Outlet | ||||||||||||||

| Installation and Mantainance Requirements | ||||||||||||||

| Expected Useful Life (years) | ||||||||||||||

| Safety accessories | Vessel | Jacket (Coil) | ||||||||||||

| Location | ||||||||||||||

| Type | ||||||||||||||

| Specification | ||||||||||||||

| Quantity | ||||||||||||||

| Set pressure(Mpa) | ||||||||||||||

| Burst disc | ||||||||||||||

| Burst pressure(Mpa) | ||||||||||||||

| Safety discharge(kg/h) | ||||||||||||||

| Agitator | Type | |||||||||||||

| Impeller Diameter(mm) | ||||||||||||||

| Speed(r/min) | ||||||||||||||

| Motor | Model | |||||||||||||

| Power(kw) | ||||||||||||||

| Explosion Proof Grade | ||||||||||||||

| Speed reducer | ||||||||||||||

| Piping Table | ||||||||||||||

| No. | Dimension | Pressure | Connection Size Standard | Connection Surface Type | Function | |||||||||

| a | ||||||||||||||

| b | ||||||||||||||

| c | ||||||||||||||

| d | ||||||||||||||

| e | ||||||||||||||

| f | ||||||||||||||

| g | ||||||||||||||

| h | ||||||||||||||

| j | ||||||||||||||

| k | ||||||||||||||

| Other Requirements if any | ||||||||||||||

Kindly fill this form for our quote.

https://luhaochemreactors.en.made-in-china.com/product-list-1.html

>> High Quality High Performance Smart Dual Panel MMDS Down Converter

>> Air Filter 222-9021 for C at Tractors

>> Electronic carton charger USB platoon insert paper packaging box earphone headset package cable paper box

>> Factory Direct Deluxe Fitness Easy Foldable Motorized Treadmill Cinta De Correr

>> Industrial Decanter Centrifuge From Shenzhou Centrifuge

>> Ring Die Poultry Animal Livestock Cow Poultry Chicken Cattle Fish Rabbit Feed Pellet Making Mill Machine for Sale Price

>> Vehicle Accessories Led Daytime Running White Light For Chery Tiggo 3 2014-2016

>> Best Small Stone Crusher Marble Granite Crushing Machine Stone Mini Crusher for Stone Crusher Price

>> Plastic Bass Soft Hard Jigging Minnow Trout Spoon Wholesale Fishing Lure

>> Home Appliances Plastic ABS/PP/Delrin Injection Mould Process Conneccting Accessories

>> Wood Chipper, Hot Sale Pallet Horizontal Drum Crusher Machine Wood Chipper

>> Used Concrete Pump Truck 38m on 2020

>> 2022 Hot Sale Wholesale Custom Pipe Die Cast Junction Box

>> 25W-65W Centrifugal Blower for Gas Boiler, Gas Boiler Blowers Centrifugal Fans

>> Longway Monterey V1100 Metal Roofing Glazed Tile Roll Forming Machine with Flower Cut

>> Natural Dry Goji From Ningxia China 380 Grains Health Foods

>> Scb-1600/10/0.4 Three Phase 1600kVA 10kv Dry Type Distribution Transformer

>> cheap kitchen faucet stainless steel 304 water tap modern kitchen taps brass 360 degree sprayer kitchen mixer sink faucets

>> Cfine 9 Inch Rubber Silicone Two Roll Rubber Mixing Mill Lab Small Open Mill for Plastic Industry

>> Convenient manual rotary extrusion Household Plastic squeezer Portable Fruit Juice Maker for orange

>> Lanhao Tech Customized Professional Pane Bending Machine for Kitchenware

>> High Quality Good Price 350000m3 Capacity AAC Production Line Alc Block and Panel Making Machine Supplier and Manufacturer.

>> Cutter New 2024 Machine Laser Cutting CNC with Good Price Dpx-J3015

>> High Precision Leveling Machinery Agriculture Farm Laser Land Leveling Grader

>> Low Price Custom Metal Fiber Laser Cutting Machine 1500W 3000W 6kw Laser Cutting Machine for Cutting Metal Aluminum Stainless Steel, Carbon Steel Plate

>> 2021 New Arrivals Eyelash Curler Comb Eyelashes Separator Makeup Tweeers Applicator Comb With Mink Eyelashes Applicator Tools

>> Customized Box 50 pcs Disposable Black Surgical Medical Face Masks

>> Engineering plastics Amber Color Polysulfone PSU Sheet and Bar PSU Rods

>> 7-21.5 Inch LCD HD Digital Photo Frame Perfect Cheap Digital Picture Frames

>> 2022 New Style 100% Polyester Classic T-shirt Customization