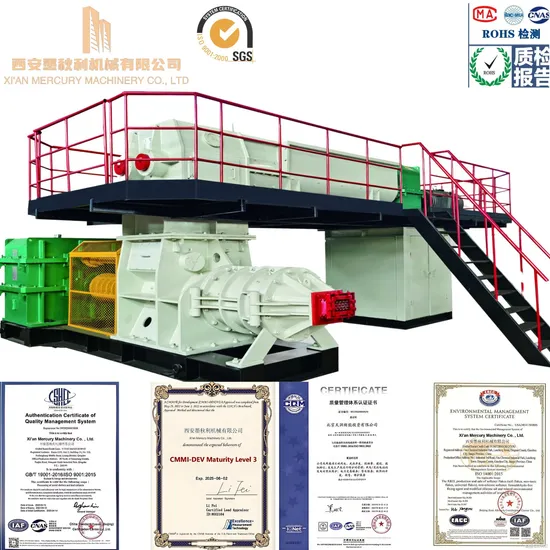

Industrial Hydraulic Compression System for Automatic Hydraulic Brick Making Machine with 300-Ton Pressure Capacity

| US$30,000.00-33,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

JKY60/60-40

Certification

CE, ISO

Customized

Customized

Automatic Grade

Automatic

Type

Hydroforming

Molding Method

Extrusion Molding

Standard

European Standard

Application Scenarion

Brick Factory

Dimensions

Based on on-Site Inspection

Factory Span

Based on on-Site Inspection

Payment Term

Tt or as Negotiation

Technical Support

Supported

Design Drawings

Supported

Packing

Container

Transport Package

Support Land and Sea Transport

Specification

50/50 60/60 70/75 90 120

Trademark

Mercury

Origin

China

HS Code

8474809090

Production Capacity

200000 Pieces Per Day

Product Description

Automatic Brick Making Machine Jkb60 From Xian Mercury Machinery Hydraform Block Making MachineIndustrial Hydraulic Compression System for Automatic Hydraulic Brick Making Machine with 300-ton Pressure CapacityProduct Description

Tunnel kiln is computer-controlled, continuously operating kilns. Pushers move the train of cars non-stop at the predetermined rate. This method is ideal for all ceramics industries which require high volume production or the continuous production process. Computer technology allows kiln car move through the kiln to be controlled for changes in firing curves and firing temperatures. This increases the product recovery and minimizes production disruptions. Automation controls can be programmed to make firing changes for different product. Product Parameters

Technical Parameters

| Model | 3.6 Meter (inner width) |

| Output (standard pcs/day) | 70000-100000 |

| Brick size | 254*115*70mm |

| Firing Cycle (h) | 35-45 |

| Firing pass(%) | 95 |

| Suitable for the products | Suitable for good quality solid bricks & hollow bricks or any kinds of Facing Bricks (high hollow ratio) |

| Coal feeding method | Both automatic and manual is ok |

| Height for dried brick stacking (layer) | 14 layers |

| Automatic Level | High automation level, equipped with fully automatic loading & unloading system |

PRODUCT FEATURE

1. Computer control:

Tunnel Kiln is completely controlled by computer, include the car moving speed, firing temperature, etc. Through the control of all details, we can make sure the firing quality. Also it can reduce the labor cost.

2. Big capacity and land-saving.

The brick setting on Kiln car can be 14 layers high which increase the loading capacity. Compared with Hoffman kiln, is also occupy less land.

3. Well-distribution of temperature, low energy consumption of product, environment friendly.

Tunnel kiln is very burning efficient, which not only save fuel cost, but also product less pollution. So, tunnel kiln is also environment friendly solution.

4. Uniformed color, good appearance, high strength. Wide adoption of decoration bricks and insulation blocks.

The well-control of temperature makes sure of the high and suitable firing temperature, which can produce good looking as well as high strength bricks.

Company Profile

Company Information

Xi'an Mercury Machinery Co. , Ltd. is specialized in the brick industry for the whole project design, kiln design, project construction and management etc.. it is one of Xi'an High Tech Enterprises.It starts to explore international market from 2007, and build many brick production lines in Bangladesh, India, Pakistan, Brazil, South Africa, Mozambique, Mexico, Russia, Venezuela,Kazakhstan, Vietnam and other countries. It has been gained many high reputations from customer and partners and constructer. We devotes ourselves to business philosophy of the Pursuit of the Excellent Chinese manufacturing Brand, establish brand awareness and serve awareness among our staff, and provide an one-stop service to customer. We not only produce brick&tile making machine,but also major in and turn-key project forproviding solutions to brick & tile making industry .

After Sales Service

Our Services

brick production line.

Our service:

1.We majors in the abroad & home fired-brick designing, kiln designing, factory building designing and turn-key project.

2.We have many professional specialists, among which 6 are professor-level engineer and 10 are of high title.

3.We have accomplished over 50 brick projects of engineering, trading, technical support in Asia, Africa and South American countries.

4.We have also successfully constructed over 20 production lines in China.

Before-sale services:

(1) Tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery.

In-Sale services:

(1)Quality control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

After-sale services:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:

1. Daily wear and tear

2.mishandling or improper operation

3. Incoming power supply fluctuation

4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication.

FAQ

1. what's the raw material for producing bricks?

Answer: clay,mud,gangue,shale etc.

2. how much land area for building a new brick plant?

Answer: it need above 20,000 square meters,the land area relate with capacity

3. when you need our proposal and quotation,what you have to mention in your inquiry.

Answer:please provide daily capacity,the brick size and you want to build a new brick plant or brick making machingery only. so we can give the proposal and offer accordingly.

4. what's the Trade terms?

Answer: it can be EXW,FOB,CIF,CNF,FCA,CPT, CIP

Xi'an Mercury Machinery Co., Ltd. is engaged in the renovation and upgrading of the old brick factory. We offer you equipment and technology for the construction or modernization of brick factories with a capacity of 5 - 120 million conventional bricks per year, including the study of raw materials, supply, installation supervision and commissioning of turnkey equipment with warranty tests. Brick firing and drying systems are made both on gas and solid fuel (coal, petroleum coke, wood waste) or fuel oil. We can manufacture spare parts for the equipment according to customer requirements

>> Horizontal Blender Mix Stainless Steel V Type Dry Powder Mixer B

>> Mens Pinstripe Embroidered Baseball Jersey Custom Stripe Baseball Jersey with Embroidery Short

>> 12 Inch Latex Pocket Coil Spring Blue Mattress in a Box

>> Stainless steel clothes rack landing indoor up and down telescopic clothes rack clothes rack

>> Electric Hot and Cool Mixing Machine for PVC Powder

>> Startnow NEMA23 Stepping Motor 573s15-L with Synchronous Pulley 5.8A Axis Diameter 8mm 6 Wires Leadshine Stepper Motor

>> Xingji 1.56 Photochromic Anti Blue Blue Cut Resin Optical Lens

>> Good Quality 30W PA Ceiling Bluetooth WiFi Speaker with Tweeter (LTH-8316)

>> CE Certificated Automatic Acrylic Plastic PVC Sheet Bender Machine

>> Stable Operation Low Noise Saving Space Parallel Shaft Helical Gear Reducer Gearbox

>> Air Recycling PP Film Waste Plastic Recycling Machine

>> Gorgeous Emerald Green Empire off-Shoulder Ball Gown Quinceanera Wedding Party Dresses

>> small urea briquette press machine with CE approved

>> Douwin Tthotel WiFi Gateway Online Wireless Network Hotel Lock System

>> FM&UL Flexible Hose for Sprinkler Used in Fire Protection System

>> Best Sourcing Agent in Yiwu with Low MOQ and High Quality Service

>> Chinese Air Transport to Poland, Atomizer, Sensitive Special Goods Such as Food, Portable Power Banks, Cosmetics, etc

>> Manufacture 10% off Full Automatic 6 Cavity Pet Bottle Blow Moulding Machine

>> Small High Pressure Secondary Concrete Transport Pump for Construction

>> ATX Modular Power Supply RS-232/RS485 Desktop Computer Power Supply

>> Home Gym Fitness Dumbbells Strength Training Yoga Pilates Silicone Dumbbell Bars

>> Hone Polypropylene Anti Corrosive Mixer Machine for Strong Acid Bleach/Floor Cleaning/Toilet Cleaner Making Machine

>> Sinicline Gold Plating Customized Logo Metal Plates for Swimsuits

>> Mortuary Equipment Stainless Steel Corpse Lifting Equipment

>> New Polished Progressive Die Punch for Aluminum

>> High Precision Gap Bed Lathe Machine CS6250, Metal Turning Lathe, Horizontal Lathe Machine

>> Single Step Automatic LED Lamp Injection Blow Molding Machine

>> ASME Standard Morocco LPG Filling Propane Transportation Trailer for Sale

>> High Pressure Boiler Seamless Alloy Steel Pipe 16mo3 P235gh 13crmo4-5 Alloy Steel Pipe

>> Made in China Factory Farm Machine High-Speed 6/8 Rows Riding Paddy Rice Planting Transplanter