2600mm Honeycomb Paper Core Machine with Starch/PVA and Steam Technology

| US$530,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HX2600-1100G

Condition

New

Certification

ISO 9001:2000, CE

Automation

Automatic

Suitable for

Recycled Material, Paper

Paper Thickness

Normal Specification Paper

Material

Starch/PVA

Heating

Steam

Opearting Person

3

Production Time

5month

Type

Automatic Paper Feeding

Side Length of Honeycomb

Can Be Customized According to Customer Needs

Transport Package

5 40hq

Specification

35300mm *6000mm *3800mm

Trademark

meixun

Origin

China

Production Capacity

10 Sets/Year

Product Description

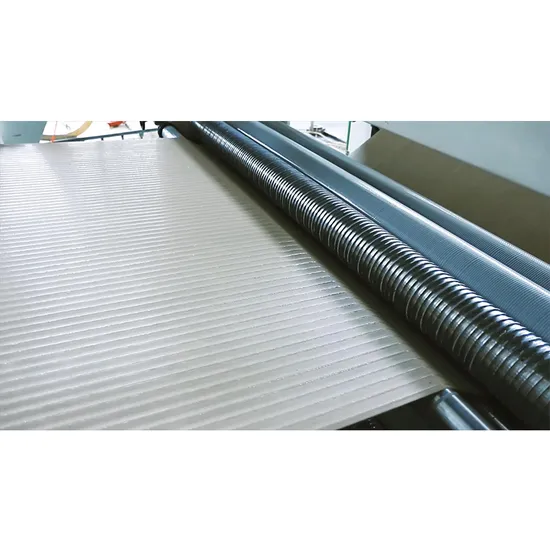

2600mm Honeycomb Paper Core Machine with Starch/PVA and Steam Technology Product Description| parameters | Specifications | |

| 1 | Effective width of core paper | 1300mm-2600mm |

| 2 | roll diameter) | φ1400mm |

| 3 | Core paper weight | 80g/M²-150g/M²(Medium to high strength corrugated paper) |

| 4 | Adhesive | Starch glue,PVA |

| 5 | Finished paper core thickness | 5-60mm |

| 6 | Honeycomb paper core cross-cut production speed | 1100cuts/min(Thickness6mm,paper core weight90-120g) |

| 7 | Honeycomb hole side length | To be determined |

| 8 | Honeycomb flatness | ±0.1mm |

| 9 | Heating method | Steam heating |

| 10 | Equipment installed power | Approximately50KW |

| 11 | normal production power consumption | 50KW*50%-60% |

| 12 | Total weight of equipment | Approximately80T |

| 13 | Equipment dimensions | 35300mm length×5600mm width×3800mm high |

| 14 | Equipment operation direction | To be determined |

Main technical parameters of the equipment: Discover the impressive specifications that set the 2600mm Honeycomb Paper Core Machine apart. With precision engineering, this machine boasts advanced features such as optimal power consumption, streamlined operations, and high-speed production, ensuring consistent output and durability, making it an indispensable asset for manufacturing excellence.

| 2600 paper core machine project configuration table | |||

| part name | project | Remark | |

| 1 | Core paper unwinding unit | Hydraulic Shaftless Paper Holder (with simple paper changing Components) | |

| 2 | aisle on the platform | Rack Transition Parts | |

| 3 | Core paper gluing unit | Core paper gluing parts ( can be equipped with double- toothed rollers) | |

| 4 | Core paper composite drying unit | Single group ( can be equipped with double pressure rollers) composite traction parts , equipped with 2 groups of composite drying | |

| 5 | Cross cutting machine unit | High-speed cross-cutting machine parts | |

| 6 | Paper core automatic collection unit | Finished paper core automatic collection part | |

| 7 | heating method | steam heating | |

| 8 | Main control component brand | Mitsubishi, Inovance, Lenze | |

Certifications

Detailed Photos

Packaging & Shipping

FAQ

>> Aluminum Punching Parts

>> HRA-II TCM diagnosis and treatment equipment for diabetes Cardiovascular disease and thrombosis

>> Custom-Made Hydraulicfloor to Floor Car Elevator Scissor Car Lift

>> Boshida Customized Auto Focusing 300X200mm Mrasure Range Image Measurement Microscope

>> Sustainable Oxford Fabric Furniture Cover Textiles for Woven Bag Lining Tent

>> Electric Foldable Space Saving Half Body Jade Rollers Massage Table Bed

>> Rubber Wheel with Bearing Dac37740045 Wheel Bearing for Ford Focus

>> 6m Single Mast Aluminum Alloy Aerial Work Platform Vertical Lift with High Efficiency

>> Simple Design Wrought Sheet Iron Double Door arched wrought iron door

>> Cast iron kitchenware enamel nonstick shallow casserole

>> Casting Press Ring for Farming

>> Black Folding Scooters for Teenagers and E Scooters for Adult Gas Scooter

>> HOWO Truck Water Hydraulic Concrete Mounted Pump 37 M 52m 62m 70m

>> Horizontal Barrel Corrugated Roofing Sheet Metal Thin Steel Making Machine Easy to Operate Roll Forming Machine From Zhongke

>> CNC Automatic Milling with High Stability and Precision

>> Horizontal CNC Thread. Worm Whirlwind Milling Machine

>> Factory Price NPK Granular Compound Fertilizer for Crop

>> Aluminum windows prices in morocco

>> Municipal solid waste sorting processing equipment garbage trommel screen manufacturer

>> Disposable SMS Isolation Gown High Quality Work Suit

>> Wholesale price custom one step medical best hcg pregnancy test

>> Wholesale Auto Spare Body Parts Car Front Door Panel For Camry 2015-2017 USA Version 67002-06221 67001-06221

>> Custom Plastic Mould Maker Injection Molding

>> 24 years' factory supply strict quality control dust filter end caps

>> Heavy Fabric Weaving Water Jet Loom Model

>> High quality car rear door lower hinge LH for 13501714

>> Wholesale Wall Board Saw Garden Gardening Saw Logging Saw Japanese Branch Saw Hand Board Saw Dovetail Saw

>> Fire Truck Manufacturer: Customized HOWO Cnhtc Truck Fire Truck Bidding Fire Truck Sales Points

>> Premium OEM/ODM Cold Rolled Steel Stretch Oil Seal Components

>> Flame Retardant Nylon Oxford Coating Waterproof Fabric for Indusry