Surgical Titanium Product Gr2 Gr3 Pure Titanium Ultra-Fine Wire for Medical Stapler

| US$30.00-430.00 | 1 kg (MOQ) |

Basic Info.

Model NO.

BKTW-M

Technique

Hot Rolled, Hot Rolled

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23, Gr1, Gr2, Gr3, Gr4, Gr5, Gr9, Gr23

Shape

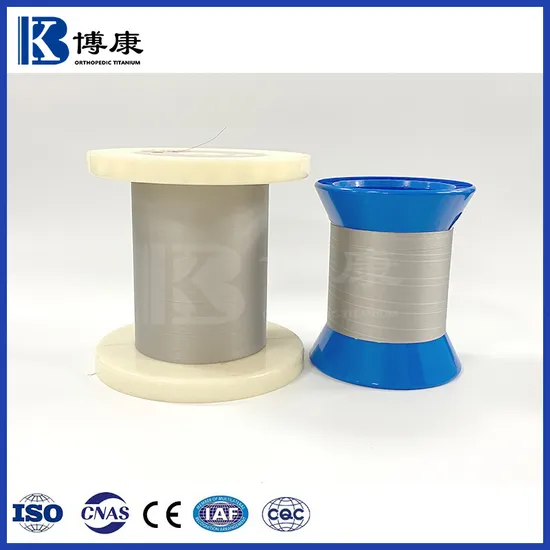

Round, Straight Wires, Coils, Spools

Tolerance

H6, H7, H8, H9

Condition

Annealed (M), Cold Rolled(Y), Hot Rolled(R)

Surface

Bright Surface

Standard

ASTM, ISO, AMS, JIS, DIN

MOQ

1kg

Material

Pure Titanium and Titanium Alloy

Transport Package

Wooden Case

Specification

Dia 0.1~4.75mm

Trademark

Bokang

Origin

Changzhou, China

HS Code

8108901090

Production Capacity

200tons/Year

Product Description

Product Description Titanium Wire Description:Titanium wires are made through multiple drawing processes. We have a variety of titanium and titanium alloy titanium wires, including 0.20-0.28 titanium wires for surgical staplers, 0.8-4.0 straight wires for orthopedics and dentistry, industrial titanium welding wires, and other wire series.

We stock a wide range of titanium wires, including commercially pure and medical-grade titanium wires. Wires can be supplied in any length required.

Titanium Wire Specifications

| Grade | Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6Al-4V),Gr9(Ti-3Al-2.5V),Gr23(Ti-6Al-4V ELI),etc |

| Standard | ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4963;AMS4965;AMS4967;ASTM B348; ASTM B863 |

| Diameter(mm) | 0.1~4.75mm |

| Shape | Straight, Coils, Spools |

| Condition | Annealed (M), Cold rolled(Y), Hot rolled(R) |

| Surface | Bright Surface |

Titanium Wire Features:

High Surface Finish

Good Roundness

Small Tolerances

High Dimensional Consistency

Stable Performance

Uniform Composition

Fine Grain Organization

Excellent Overall Performance

Long Fatigue Life

Titanium Wire Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Machining→Forging Billet→UT testing→Rolling Billet→Online Straightening→Centerless Lathe→UT testing→Rolling→Metallographic Inspection→Wire Drawing→Precision Straightening→Heat Treatment→Mechanical test→Microstructure test→Centerless Grinder→Eddy Current Test→Polishing→Visual and dimension inspection→Product Marking→Packaging→Delivery

Applications of Titanium Wires

1. Medical: Used in surgical implants like bone screws, dental wires, and cardiovascular stents due to its biocompatibility and resistance to bodily fluids.

2. Aerospace: Essential for aircraft components such as fasteners, springs, and electrical connectors due to its high strength-to-weight ratio and resistance to corrosion.

3. Chemical Processing: Employed equipment for handling corrosive chemicals and acids, such as valves, fittings, and mesh screens, due to their corrosion resistance.

4. Electronics: Utilized in electronic devices for wire bonding, connectors, and antennas due to its conductivity and resistance to corrosion.

5. Jewelry: Found in high-end jewelry for its hypoallergenic properties, durability, and ability to be colored through anodizing.

6. Art and Design: Used by artists and designers for sculptural works and architectural installations due to its malleability and aesthetic appeal.

7. Automotive: Employed in automotive applications such as exhaust systems, springs, and suspension components for their lightweight and high strength.

8. Sports and Recreation: Utilized in sports equipment such as bicycle frames, fishing rods, and golf club shafts for its lightweight and durable properties.

Chemical Composition Chemical Composition

ASTM F67 Chemical Requirements:

| Element | Composition,% (mass/mass) | |||

| Grade 1 UNS R50250 | Grade 2 UNS R50400 | Grade 3 UNS R50550 | Grade 4 UNS R50700 | |

| Nitrogen, max | 0.03 | 0.03 | 0.05 | 0.05 |

| Carbon, max | 0.08 | 0.08 | 0.08 | 0.08 |

| Hydrogen, max | 0.015 | 0.015 | 0.015 | 0.015 |

| Iron, max | 0.2 | 0.3 | 0.3 | 0.5 |

| Oxygen, max | 0.18 | 0.25 | 0.35 | 0.4 |

| Titanium | balance | balance | balance | balance |

Analysis Tolerances

ASTM F67 Analysis Tolerances:

| Element | Limit or Maximum of Specified Range %(mass/mass) | Tolerance Under the Minimum or Over the Maximum Limit |

| Nitrogen | ≤0.05 | 0.02 |

| Carbon | 0.10 | 0.02 |

| Hydrogen | ≤0.015 | 0.0020 |

| Iron | ≤0.25 | 0.10 |

| Iron | >0.25 | 0.15 |

| Oxygen | ≤0.20 | 0.02 |

| Oxygen | >0.20 | 0.03 |

Mechanical Properties Mechanical Properties

ASTM F67 Mechanical Requirements: Annealed-Bar, Billet, Forgings, and Other Forms

| Grade | Tensile Strength, min | Yield Strength, A (0.2 % Offset), min | Elongation in 4D, min, % | Reduction of Area, min, %C | |||

| KSI | MPA | KSI | MPA | ||||

| 1 | 35 | 240 | 25 | 170 | 24 | 30 | |

| 2 | 50 | 345 | 40 | 275 | 20 | 30 | |

| 3 | 65 | 450 | 55 | 380 | 18 | 30 | |

| 4 | 80 | 550 | 70 | 483 | 15 | 25 | |

ASTM F67 Round Wire Size Tolerances:

| Diameter, in(mm) | Size Variation, in. (mm) | Out of round, in. (mm) |

| 0.125~0.3125(3.18~7.94) | ±0.002(0.051) | 0.002(0.051) |

| 0.030~<0.125(0.76~<3.18) | ±0.001(0.025) | 0.001(0.025) |

| 0.010~<0.030(0.25~<0.76) | ±0.0008(0.020) | 0.0008(0.020) |

| 0.005~<0.010(0.13~<0.25) | ±0.0005(0.013) | 0.0005(0.013) |

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

About Bokang

Our Advantages

FAQ Q: Are you a direct manufacturer or trading company?

A: We're a manufacturer with more than 18 years of professional production experience.

Q: Do you offer free samples?

A: Usually, our sample is free but we need our customer to pay the freight.

Q: What is the minimum quantity per order?

A: 1 kg. For regular standard medical and aerospace materials, based on our production capacity of 20 tons per month for titanium wire and rods. the stock inventory could meet all your requirements.

Q: What products can you offer?

A: We specialize in the production of pure titanium, titanium alloy, titanium rods, wires, discs, nitinol alloy, etc.,

Q: What's the payment term?

A: When we quote for you, we will confirm with you the way of transaction, FOB, CIF, CNF, etc.

For mass-production goods, you need to pay 30% deposit before producing and 70% balance against a copy of documents. The common way is by T/T. L/C is also acceptable.

Q: What applications do your products relate to?

A: Our titanium alloys and nitinol alloys are widely used in medical, aerospace, and other Industries.

Q: How can we get your price?

A: We need the below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

Q: Can you do customized products?

A: Yes, we support customized products according to the customers' drawings or samples.

Q: How do you guarantee the quality of your goods?

A: We ensure quality by inspecting every process and using advanced testing equipment to conduct comprehensive checks, ensuring finished products meet customer and international standards.

Q: How do you deliver the goods to us?

A: We will usually ship the goods by sea and air according to your requirements.

>> Animal Feed Chaff Chopper Hay Cutter Slicer Straw Breaker Machine

>> Australian Apartment 3D Physical Scale Building Model Residence House Model Making

>> Taijia concrete steel corrosion detector rebar corrosion scanner Tester

>> Datang China High Quality Universal Edge Milling Machine

>> Transparent Oil-Proof Epoxy Resin Speed Electronic Ab Glue for Electronics Components

>> Taijia wireless weighing system load cell manufacturers 3 Tons Dynamometer Tension Meter

>> High Technology 10t~32t Zhxxxbs Standard Double Girder Hoist for Double Beams Crane

>> Upholstered Modern Furniture Storage Beds

>> Leland Koala High Quality Sleep Well Twin Single King Size Gel Memory Rebonded Foam Mattress

>> high speed snack food pouch packaging machine for almond packing filling snacks machine

>> Factory Good Price with Bluetooth FM USB AC Adapter Solar Power Solar LED Wall Light Solar Power Station

>> Holdwell Replacement New Oil Filter Bc3z-6731-B for Truck F-350 F-450 F-550

>> 9.1oz Cotton Polyester Spandex Twill Dobby Denim Fabric for Jacket

>> Ultrafine Powder Grinding Pulverizer Hammer Mill for Pharmaceutical/ Food/ Chemical

>> Latest Metal Mesh Forming Stainless Steel Wire Winding Vertical Wire Braiding Machine for Metal Hose

>> Mgehr2525-4 CNC External Grooving Turning Tools Applicable Inserts Mgmn400-M

>> Jacquard Zipper up High Collar Women′s Cardigan for Winter

>> 254mm Wood Circular Saw Blade Tct Sharpener Grinding Machine with Auto Loading System

>> Everich Ice Chest Cooler Box Fishing Hard Cooler Box Roto-Molded

>> Customized 48V 100ah Ion Li LiFePO4 Storage Pack Gel Solar Lithium Battery

>> PE Recycling Line Equipment with Wash Line System for Plastic Granules

>> High Precision Dual Spindle CNC Turning Center By32s 2 System Machine Tool

>> Singfiller Remove Wrinkles and Volume Filling Injection Hyaluronic Acid Dermal Filler

>> Fashion Black Leather Paper Rectangular Paper Gift Perfume Packaging Box

>> Wool Mark Certified Pure Australian Merino Virgin Wool Blanket

>> SHENGKE Delicate Ladies Watch Diamond Cutting Glass Unique Dial Soft Leather Band Quartz Movement Watches Custom Logo OEM K8053

>> Era Plastic/Pph Thread Pipe & Fitting Iram 13478 Pipes

>> Aogao Solid Compact Density Fiberboard Panel HPL Phenolic Waterproof Compact Panel

>> High Quality and Low Price Automatic Electric Tapping Machine with Tapping Screw Drilling and Tapping Machine

>> OEM ODM Soft Baby Dolls Stuffed Plush Toy Rag Girl Doll Mu100379 with CE En71 Gcc