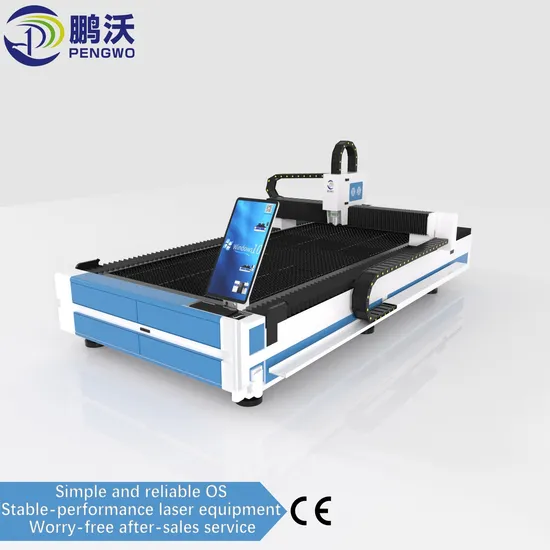

Versatile Fiber Laser Cutting Machine 3000W 2mx4m Single Table Job Shop Cutting

Basic Info.

Model NO.

G2040F-A

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Aerospace

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Power

1500W-30000W

Cutting Thickness

0.5mm-80mm

Energy Consumption Level

Low

Customized

Yes

CNC or Not

CNC

Cutting System

Optional

Transport Package

Wrapping Film and Plastic Soft Bag

Specification

4700*2700*1800

Trademark

PENGWO

Origin

Shandong, China

HS Code

8456110090

Production Capacity

5000pieces/Year

Packaging & Delivery

Package Size

4750.00cm * 2800.00cm * 1850.00cm

Package Gross Weight

2000.000kg

Product Description

Product DescriptionCore Advantages

Industry's mainstream laser source

Unparalleled stability and energy efficiency

Powerful and durable laser heads

Multiple mainstream brands available to provide the best solution

Simple and intelligent CYPCUT system

Professional engineers provide operation training

7X24 after-sales service

Exclusive after-sales service to answer questions at any time

Product Parameters

| Name&Model | Laser Cutting Machine G2040F-A |

| Working Area | 2000*4000 |

| Laser Power | 1500W/2000W/3000W/6000W/12000W/20000W//30000W/60000W |

| Machine Structure | Stable & strong welded bed with high temperature annealing |

| Beam | Aviation aluminum/Integrated cast aluminum beam |

| Applicable Material | Carbon Steel Stainless Steel Etc( Metal Laser Cutting Machine ) |

| Laser Source Brand | MAX/RAYCUS |

| Key Selling Points | Automatic |

| Warranty | 2 years |

| Condition | New |

| Moving Speed | 120m/min |

| X axis travel (mm) | 2030 |

| Y axis travel (mm) | 4050 |

| Z axis travel (mm) | 80 |

| Max acceleration | 0.8G |

| Position Accuracy | ±0.03mm |

| Repositioning Accuracy | ±0.02mm |

| Computer | Industry Computer |

| Transfer method | Gear rack dual drive |

| Working Voltage | 220V/380V,50hz/60hz(customized) |

| Dimension | 4700*3200*1800 |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST DWG, LAS, DXP |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Applicable Material | Metal Steel Carbon Copper |

Detailed Photos

Nestled in the thriving city of Dezhou, Shandong Province, Shandong Pengwo Laser Technology Co., Ltd. has been a beacon of innovation since its inception in 2005.

Specializing in the R&D and manufacturing of state-of-the-art laser processing equipment, the company delivers intelligent manufacturing solutions tailored to customer needs. Thanks to relentless development and technological prowess, Shandong Pengwo stands as a vanguard in the domestic laser application equipment market.

Our expansive production facilities span over 80,000 square meters across Dezhou Tianqu New District and Pingyuan County, reflecting our commitment to excellence and growth.

After Sales Service

Installation training (3 options) :

A. Experience seamless integration with our comprehensive support! We provide you with detailed installation, operation, maintenance, and troubleshooting guidance through videos and English user manuals. Encounter any issues? Fear not, our technical experts are just a message away, ready to assist you via email, fax, phone, Messenger, WhatsApp, and more.

B. Embark on an enriching journey to China for hands-on training, complete with complimentary accommodation.

C. Benefit from China's exceptional after-sales service team, dedicated to ensuring your satisfaction at every step.

Our proficient engineers, fluent in English, are equipped to address your concerns and facilitate seamless communication. Additionally, we can arrange flight services for your convenience.

Training time:

3-7 working days (recommended). Enjoy complimentary installation, commissioning, and training at your personal work site. While this invaluable service is provided at no cost by the supplier, please note that the buyer is responsible for covering the supplier's airfare (round trip), as well as food, accommodation, local transportation, translation, Internet, communication, and visa expenses, as per actual documentation.

Certifications

FAQ

Q1. When was your factory established?

We have been specialized in the R&D, manufacturing and intelligent manufacturing solutions of laser processing equipment since 2005, mainly focusing on laser processing equipment such as fiber laser cutting, laser welding equipment, laser cladding equipment, etc.

Q2. What should I do if there is a problem with this machine during the warranty period?

The quality assurance period is 12 months from the date the goods arrive at the destination port. Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period. After the quality assurance period, if you need to repair or replace parts, you must pay.

Q3. How to install and use?

We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the machine. When you encounter installation, use or adjustment problems, we will provide technical guidance by email, fax, telephone/Messenger/WhatsApp, etc.

Q4. What should I do if there is an after-sales problem?

You can directly describe your problem to the after-sales staff. China's strong after-sales service team. Our engineers (employees) can communicate and solve problems in English, and can be arranged once a day per person when you need it. If I need to go to your place to help, I will quickly arrange to go there and quickly fly to help you.

Q5. How about wholesale price?

If you are a wholesaler, distributor or agent, please contact us to get wholesale price.

>> Hot Sale Single Wall Disposable Custom Paper Cup Making Machine for Hot Drinks

>> Paper Cup Pad Making Printing Machine

>> Women′s Fashion White Black Stripe PU Leather Stiletto High Heels MID-Calf Short Boots

>> High Speed Automatic Veneer Peeling Line 4FT and 8FT for Plywood Machinery

>> Outdoor Sport Game Inflatable Palm Slide for Children

>> Customization New Trendy Good Quality 30s 140GSM Rayon Printed Floral

>> Em slimming sculpt machine electromagnetic field muscle stimulation

>> CNC Gantry Milling Double Column Machining Center XH3022 XH4022 XH5022

>> 200W LED COB PAR Can Stage Light 4X50W Warm Cool White LED COB Blinder Stage Light LED Wash

>> Hsy128 Mattress Production Line Industrial Automatic Fabric Sewing Textile Shuttle Multi Needle Single Quilting Machine

>> 100% Cotton White with Grey Embroidery Bedding Set

>> China HDD Pipe Drill Rod Horizontal Directional Drilling

>> Outdoor Anti-Corrosion Engineered Solid Strand Woven Bamboo Flooring Garden Deck Bamboo Decking

>> LED Ophthalmic Surgical Microscope for Cataract Removal

>> Indoor High-End Ultra-Thin P1.875 LED Screen

>> Truck Tractor Tubeless Tire Valve Stems Wheel Rim TR618A

>> New Design High Pressure Homogenizer Laboratory Machine Homogenizer Mixer

>> 1000kg Mini Small Little Hydraulic Crawler Backhoe Excavator for Garden and Farm

>> 1000 Lph Mini RO Steel Reverse Osmosis Filter with Water Purifier

>> Wholesale Smoke Detector Fire Alarm Zigbee Smoke Detector with Battery

>> washer label film automatic roll laminating machine

>> Wholsale Udl Xm1014 Soft Bullet Gun Shell Throwing Airbrush Simulation Toy Gun

>> Fujitang - Premium Black Fungus Edible Guangdong Mushroom for Qi and Blood Support

>> Brake Shoe Riveting Machine for All Truck Brake Shoes

>> Manual Pressure Sprayer Hand Air Pressure Sprayer Disinfection Pump Pressure Sprayer

>> Taijia TEM-91 digital rebound hammer sclerometer rebound test digital test hammer

>> New liquid silicone phone case TPU PC Phone case Colorful Card Portable phone accessories case for iPhone 14 /13ProMax

>> German Style Large Tempered Glass Aluminum Profile Louver Interior Glass Door for Sale

>> Plastic Household Products Injection Mould

>> Best Price Pet-2000 CE Approved Waste Pet Plastic Recycling Production Line Recycle Making Machine for Sale