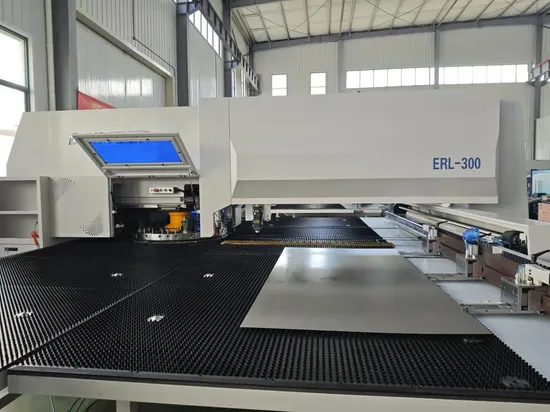

30tons, 28/32 Tool Station, 6.35mm Thickness Turret Punch Press with Laser Cutting Function

| US$91,000.00-115,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

ERL-300

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Desktop

Laser Classification

Gaseous Laser

Laser Technology

Composite Cutting Process

Punch Force

30 kN

Max. Processing Sheet

2500* 1500 mm

Max. Processing Sheet Thickness

6.35 mm

Max. Punch Diameter

88.9 mm

Accuracy

±0.1 mm

Servo Unit

Panasonic, Synmot, Sano

Loading

20ot, 40gp Container

Package

Foam and Plastic Film, Customized

Color

Blue, or Customized

Linear Guide and Ball Screw System

Japan NSK/ Tsubaki, Taiwan Hiwin/Tbi

Servo System

Rexroth

Stamping Stroke

40mm

Workstation

32

Punch Stamping Frequency

1800 Hpm

Number of Control Axes

6/7

Transport Package

Pallet, Foam and Plastic Film

Specification

5500*5200*2280 MM

Trademark

Dontzer

Origin

China

HS Code

8462111000

Production Capacity

200 Sets/Year

Packaging & Delivery

Package Size

1203.00cm * 235.00cm * 239.00cm

Package Gross Weight

17000.000kg

Product Description

Product OverviewThe CNC punching and cutting composite machine has both servo punch forming processing technology and the characteristics of high laser cutting efficiency and good cross-sectional quality.

The optional automatic tapping function can achieve punching, forming, scribing, lettering, rib rolling, laser cutting, and tapping.

It can provide a new intelligent manufacturing solution for your production. This composite machine includes a punch press mainframe, laser cutting system, and electrical components. The composite machine adopts a full German Rexroth CNC system, motor, and drive.

Detailed Photos

* Steel plate frame

* Tempering fireplace

* One-step clamping

* Thick rotating tower

* Extending mold life

* High accuracy

* International standard 85 series mould

* High surface hardness

* Strong anti-abrasion

* Tempering clamp slide

* Blackening of clamp surface

* Installing scales

* The special fibre laser cutting head, with stable and reliable performance, ensures the best cutting quality and achieves high cutting speed.

* Non-contact capacitive sensor to ensure stable cutting follower gap, ensuring a very good cutting effect.

Product Parameters

| NO. | Specification/Model | quantity | Remarks | |

| CNC punching and cutting compound machine | ERL300 | 1 | ¨28¨ 32 workstations | |

| Laser cutting systems | systems | Rexroth Indraworks | 1 | |

| lasers | Chuangxin Maxphotonics-1500W/3000W | 1 | ||

| cutting head | Ka Keung Empower BM110 | 211 | ||

| chiller | Hanli HL-3000 | 1 | ||

| air compressor | 11kw | 1 | optional | |

| Unloading device | Custom sizes | 1 | optional | |

CNC Punch Press Parameters:

| NO. | Name | parameter | unit | Remarks | |

| 1 | punch force | 300 (30) | KN (T) | Optional 400 (40) | |

| 2 | machine structure | "O" closed type | Fireplace Tempering | ||

| 3 | Maximum sheet size | X-axis 2500 | mm | X-axis secondary positioning 5000mm | |

| Y-axis¨ 1250¨ 1500 | mm | ||||

| 4 | Maximum plate thickness | 6.35 | mm | ||

| 5 | Maximum diameter of one punch | Φ88.9 | mm | Non-standard customisation | |

| 6 | Punching frequency | 2300 | hpm | ||

| 7 | Maximum punching frequency (6mm stroke in 1mm steps) | 900 | hpm | ||

| 8 | Maximum punching frequency (6mm stroke in 25mm steps) | 400 | hpm | ||

| 10 | Mould form | Long guide 85 series international standard mould | |||

| 11 | Turret station distribution ¨28¨ 32 workstations | ¨12A, 10B, 4C, 2D (2B, 2C Auto-index) ¨16A, 11B, 3C, 2D (1B, 1C Auto-index) | standard equipment | Non-standard customisation | |

| 12 | Number of clamps | 3 | PCS | ||

| 13 | Repositioning cylinders | 2 | SET | ||

| 14 | Number of control axes | 6/7 | PCS | Non-standard customised Y-axis cutting head movement | |

| 15 | Maximum speed of plate movement | 106 | m/min | ||

| 16 | Table structure | Brush/Universal Steel Ball Composite Countertop | |||

| 17 | Maximum feed speed | X-axis | 90 | m/min | |

| Y-axis | 80 | m/min | |||

| X, Y linkage | 110 | m/min | |||

| 18 | Turret speed | 30 | rpm | ||

| 19 | Machining precision | ±0.10 | mm | ||

| 20 | Maximum load capacity | 156 | Kg | ||

| 21 | Clamp Blind Zone Detection | √ | |||

| 22 | Alarm device for loose clamp plates | optional | |||

| 23 | Anti-Warping Test for Panels | √ | |||

| 24 | air pressure | 0.6 | MPa | ||

| 25 | power supply | 380±5% | V | ||

| 26 | Weight | ¨15¨ 17 | T | ||

| 27 | Overall dimensions (L x W x H) | ¨5200¨ 5500x5200x2280 | mm | Bed colours available in red and white or custom colours | |

Product category

Company Photos

Certifications

FAQ

1. How about the delivery time?

Generally, it's 15-30 days based on the model.

2. How is the warranty time?

1 year after installation.

Lifetime free technical support.

3. How to choose a suitable machine?

Please advise us on the material/ thickness/ dimension of the metal sheet, and the punched drawing.

>> Ss Round Square Cold Hot Rolled ASTM/AISI/DIN/JIS 201 304/304L 316 316L 430 Stainless Steel Seamless/Welded Tube with Pickling Ba 2b Bright Polish

>> Galvanized /Colored Roofing Sheets Cheap Price

>> High Intensity Lifting Salvage Boat Pneumatic Rubber Airbag Ship Rubber Airbag

>> Customized Carbide Cold Heading Die Made in China

>> 40"41"Acoustic Bag Single Bag 600d Material 10mm Thickness Padding

>> Factory Custom Waterproof Children Pupil Primary Student Cute Girls Kids School Bag

>> 60kg-300kg Single Point Load Cell for Automatic Sorting Scale LC1535

>> Custom Color Cable Management Box for Desktop Storage Cable Organization

>> High Automation Machinery Waste Plastic Pet Bottle Recycling Melting Machine Washing Line

>> CNC Boring Machine (ZJA06-0606)

>> High Precision Long Service Life Needle Loom Machine

>> Exchange Table 3015 Fiber Laser Cutting Metal Stainless Steel Iron Aluminum Machine Price

>> Imported Liquid Washing Products Hand Sanitizers Production Line Stainless Steel Mixing Tank

>> Agricultural Machinery Parts Plow Plough Shovel

>> Plastic Disposable Sharps Container for Hospital Collecting Biohazard Waste

>> Wooden Case 2 Years Horizon Laser 1160X630X1140mm China Ipg Mini

>> Zaxis 60 Second Hand Excavator with Cheap Price for Sale

>> 700A. 17.17.000 Farm Parts K700 Tractor Gearbox

>> Medical Hospital Furniture ICU Patient 3 5 Function Electric Nursing Hospital Bed

>> Reflective Vest Military Reflective Suit Spillproof Reflective Vest

>> HC-W047 Mindray spare parts biochemical instrument BS300 320 sample disk assembly

>> AS2047 standard custom adjustable grey aluminium or glass single hinged louver louvered door

>> Automatic Exterior Aluminum Shutter Louvers for Window

>> Eh09 Gasoline Engine Generator 3HP

>> MQ1000 Maquina Suajadora Hidraulica Para Papel y Carton

>> Automatic rotary type high speed 5 gallon barrel bottle outside washer washing brushing machine

>> Wholesale Explosion Proof Chain Block Electric Chain Hoist for Warehouse

>> Genuine Carbon Fiber Diffuser For 2018 2019 2020 BMW 5 series G30 G38 Modified 3D Rear lip

>> Automatic Feeding Self Loading Diesel Engine Concrete Mixer Truck 2024

>> Premium Lightweight Down Sleeping Quilt for Outdoor Adventures