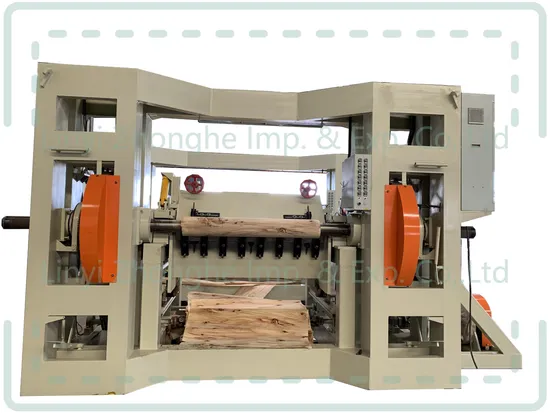

Linyi Spindle Wood Veneer Peeling Rotary Machine

| US$13,500.00-14,000.00 | 1 Piece (MOQ) |

Basic Info.

Type

Peeling Machine

Automatic

Semi-Automatic

Certification

CE, ISO

Color

Customize

Motor Power

14.3kw/17.3kw

Weight

3500 Kg

Size

3430*1500*1220mm

Veneer Thickness

0.4 - 3.6 mm

Logdiameter

900mm

Transport Package

Plastic Film / Plywood

Specification

3500 KG

Trademark

ZHONGHE

Origin

Linyi City, China

HS Code

8465960000

Production Capacity

2 Sets / Month

Packaging & Delivery

Package Size

343.00cm * 150.00cm * 122.00cm

Package Gross Weight

3500.000kg

Product Description

Spindle Veneer Peeling Machine Product DescriptionProduct Description

Spindle veneer peeling machine is used to process wood segments of a certain length and diameter into continuous veneer strips for the production of plywood, wood sheeting and other wood-based panels.

The general method of peeling is: the left and right clamp the two ends of the wood segment and drive it to rotate, the rotary knife blade installed on the cutter head is parallel to the axis of the card shaft and does feed in its vertical direction, and the veneer of equal thickness is cut out along the direction of the annual ring of the wood segment.

Advantage:

1. Efficient rotary cutting: The card rotary cutting machine adopts advanced rotary cutting technology, which can quickly and accurately complete the rotary cutting work of wood. Its efficient spinning speed greatly improves the production efficiency and reduces the production cost.

2. Precise control: The equipment is equipped with a precise control system, which can realize the precise control of parameters such as the thickness and Angle of rotary cutting. This ensures that the rotary cut wood products have consistent specifications and quality, meeting the requirements of different industries for wood processing accuracy.

3. Easy operation: There is a card cutting machine equipment design is reasonable, the operation is simple and easy to understand. Operators only need to go through a simple training, you can master the operation method of the equipment, to achieve a quick start.

Product Parameters

Product Parameters

| No. | Model | LXQ1300L-900 |

| 1 | Working log length | 1300 mm |

| 2 | Working log diameter | 900 mm |

| 3 | Veneer thickness | 0.4 - 3.6 mm |

| 4 | Motor power | 14.3 KW / 17.3 KW |

| 5 | Equipment weight | 3500 KG |

| 6 | Dimensions | 3430*1500*1220 mm |

Detailed Photos

Company Profile

Company Profile

Linyi Zhonghe Machinery Company is professional in solutions of wood veneer production machine, plywood production machine, particle board machine, MDF board machine, saw mill machine, wood veneer, plywood, other related material and parts for wood processing industry, construction material and machine, etc.The detail business range is as following:1-wood veneer production machine:Log cutting machine, log debarker, core veneer peeling machine, face veneer peeling machine, wood veneer dryer, wood veneer clipper, wood veneer stacker, veneer tape, etc.2-plywood production machine, film faced plywood machine:Core veneer composer, putty spreader, veneer sanding machine, veneer jointer, glue powder, glue making machine, glue mixer, glue spreader, base plywood forming machine, cold press, hot press, bolier, Double Dimension saw, sanding machine, wood dust collector, stainless steel plates, cushion pads, etc.3- Particle board machine and MDF board machine.4-Saw mill machine: Vertical band saw, horizontal band saw, saw blade sharpener.

Packaging & Shipping

Packing and Shipping

1. Disassemble the whole machine into parts and put them into containers for easy transportation.

2. The container will be transported to the port by special car.

3. A professional shipping team will bring your products to the port you need

4. Take the bill of lading to the port to pick up the goods

FAQ

Frequently Asked Questions

Q1:Can you customize products for clients?

A: Yes We can customize and produce woodworking machines according to the customer's requirements or drawings.

Q2:How can we trust your factory?

A:We recommend that you come to our factory to see the goodsto verify the real situation of the products,and know more about our factory.

Q3:Why does the price often change?

A:The price depends on the latest prices of the raw materials

Q4: How about delivery?

A: when the product is ready,it can be delivered to you after your full

payment.Well provide technical guidance

>> Good Service Lifejacket Air Jacket Inflatable Life Snorkeling Vest with CE Bz-Ilj-2

>> Plastic Shampoo Bottle Blow Moulding Machine

>> Lab Wool Small Carding Machine with Villus Bucket

>> Cheap Price Air Car Shipping Service Truck Freight Forwarding Russia Shipping From Yiwu Trade Market China to Russia Moscow Delivery in Russia

>> High Rigidity Ferro Silicon Calcium Cored Wire Used as an Alloy for Steelmaking Metallurgy

>> Premium Quality Latest Design Fashion Style Men Leather Wallet at Low Price

>> 11kv Drop out Fuse 11kv with Barrell 100A Rated Voltage 15kv High-Performance RS-7 Outdoor Fall Fuse

>> Vertical Hydraulic Floor Lying Jack 5t Lifting for Car with Different Color

>> Luxury 100ml Women′s Perfume - Exotic Floral Fragrance Spray

>> Customized High Quality Waterproof DC 12V 24V RGBW Color Changing Multi Color LED Strip Light

>> Wholesale Portable Detachable Outdoor Camping Backyard Stainless Steel BBQ Grill Fire Pit

>> High quality Anti-broken Gold/ Silver 2mm thick acrylic Mirror Sheet

>> Modern Glass Tabletop Fireplace Bio Ethanol Fireplace Display for Table Decorations

>> Automatic CE IBM Medical High Speed Factory Chemical Pesticide Bottles Blowing Injection Blow Molding Machine

>> Pressure Switch Tubing Silicone Tube Water Hose

>> Stainless steel filter screen washable and reusable disc filter

>> Wholesale Good Price Pumpkin / Sunflower / Water Melon Seeds and Kernels AA

>> Mr-26D Precision Mini Drill Grinder/ Twist Drill Sharpening Machine with Durable Taiwan Grinding Wheel

>> MAICTOP car spare parts modified tail light for HILUX REVO 2016 LED tail lamp

>> Modern design Apartment fire rated wood door lowes

>> 6lanes High Speed M Fold Hand Towel Machine with Lamination

>> Best 4WD Mini Tractor, High Quality Multi-Purpose Mini Tractor, Premium Manufacturer Agricultural Tractor

>> Factory Supply Rubber Hose/Delivery Pipe/Delivery Pipebend Elbow Concrete Pump Spare Parts

>> 2025 New CNC High Speed 3D Beam Drilling Machine for Metal H Steel Beams U Channel Steel

>> MY1224 Automatic Precision Hydraulic Surface Grinding Machine

>> Vertical Turbine Hollow Solid Long Axis Shaft Sea Water Industrial Irrigation Flood Drainage Submersed Water Pump

>> Boxing Equipment Sporting Goods Black Training Winning Glove Gym Boxing Gloves

>> Multifuctional Drill Tools Cordless Screwdriver with Current Detective Function (CDS027)

>> 50PCS 2.2L Tank Whipped Cracker Flavoured Cream Chargers Whipped Cream Chargers Freshwhip Nitrous Oxide Gas

>> Wholesale High Quality Multicolor Chemical Lace Net Lace Dress Fabric