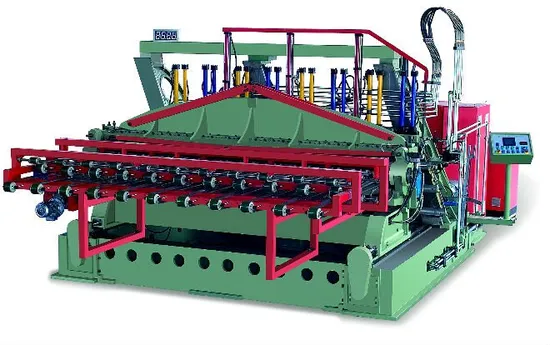

Natural Wood Veneer Slicer

| US$145,000.00-162,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

BB1342

Max Allowed Wood Size

3900*760*760

Size of Knife

4200*200*19mm

Slicing Thickness

0.2-3mm

Slicing Speed

Max.80PCS/Min

Wood Clamping Method

Hydraulic Control

Total Power

75.25kw

Main Motor

55kw

Dimension

7700*5800*4100mm

Weight

40t

Transport Package

Plastic Film

Specification

ISO9001

Trademark

HZH

Origin

China

HS Code

84659600

Production Capacity

20sets/ Month

Product Description

We supply Vertical veneer slicer for fancy veneer| Model | BB1342 |

| max allowed wood size | 3900x760x760mm |

| size of the planer tool | 4200x200x19mm |

| slicing thickness | 0.2-3mm |

| slicing speed | max.80pcs/min |

| wood clamping method | hydraulic control |

| Total power | 75.25Kw |

| main motor | 55kw(DC) |

| Hydraulic motor | 11kw |

| knife-holder feeding motor | 3.5Kw*2 |

| circulating heat water motor | 0.75kw |

| veneer transport motor | 1.5kw |

| size of body(LxWxH) | 7700x5800x4100mm |

| net weight | 40T |

Function

It is mainly for slicing solid wood, engineer wood and other composite board, working efficiency is high, and veneer thickness is uniform. It is widely adopt in decorative veneer of plywood, furniture, flooring, construction industry and so on.

Characteristic

1Main motor adopts direct current motor. Energy can be feed back by the special design, and cutting speed improved to be 80pcs/min

2 To guarantee precise veneer thickness, we use ball screw with servo motor. To avoid veneer scratch we used auto blade back system

3 Use hydraulic system, log clamping become more convenient for operator and improves efficiency

4 Control cabinet is combined with electric and hydraulic system, make it easy for single operator

5 Automatic hydraulic blade holding system, and log holder auto turn back system are fitted there, grinding and replacing the blade become so easy and quickly

6 Heating system in blade holder and press bar, avoids stain in the veneer to improve veneer quality

7 Pneumatic brake systems can stop the machine at any required position, and restart promptly. It is convenient for the operator to adjust the log, and safety also guaranteed

8 Self lubricating center can automatically apply lubricant regularly to every moving mechanism; guarantee movement normally smoothly and precisely.

Contact us

>> 2 Tier Stainless Steel Wire Rack Wall Mounted Adhesive Magic Sticker Bathroom Storage Shelf Rack

>> Lt SA5992 Hydraulic Pipe High Pressure Hose 1/4 Inch Convoluted Oil Hose for Large Scale Long Range Machinery Excavators Tractor Rubber Hose Pipe Price List

>> 0.1 mm wire stainless steel 316 knitted wire mesh

>> Plastic Blown Film Machine Extruder Solves Problems of Maintenance

>> Factory Wholesale Customized Any Design High Quality Mosque Carpet Wall to Wall Fire Resistant Carpet Nylon or Wool Printed Mosque Carpet Prayer Carpet Roll

>> Waterjet Parts 60K Intensifier Check Valve Body (004383-3)

>> Face Shield Mask Earloop Disposable For Civil Use

>> 2500mm 3 Layers Co-Extrusion LDPE Film Blowing Machine

>> Polyurethane Foam Resin for Pipe Insulation System House White Component

>> High-end imports fishing line Authentic Multicolored fishing line Professional long throw pe line 100 meters long, full range

>> Confidential Document Destruction Industrial Paper Shredder

>> Tao Motor 2024 New Shaft Driving Farm Use Quad Bike 300cc ATV

>> Kinghood Customized Metal Double Edge Blade Razor Butterfly Adjustable Razor For Face

>> Versatile Mini Excavator Bulldozer for Convenient Agricultural Use

>> custom foil selfsealing bag stand up pouch aluminum bag

>> High Quality Roadside LED Light Aluminum Reflector for Traffic Safety

>> Quality Sleep Well Cooling Swirl Gel Memory Rebonded Foam Mattress Roll in a Box

>> Byloo iso metal body good design surf casting customizable fishing reel lbd electric reel fishing diwa 1000

>> High quality low cost black patch cord cat6 rj45 cable 1m 2m 3m 5m cat 6 patch cable cat 6a

>> Pink Green White Yellow Color 3 in 1 Mult Fuction Kids Scooter

>> Plastic Sheet Roll Super Clear PVC Calendering Film Roll Plastic Product Wholesale

>> Precision CNC Milling Machine with Bt40 Spindle - Model Kdvm1160L

>> Automatic PVC PE PP ABS LDPE LLDPE High Speed Plastic Pulverizer Machine / Pulverizer Mill/PVC Pulverizer for Pipe Profile Scrap

>> High-Accuracy, Automatic Metal Ruite Wooden Case Stone Cutting Machine Diamond Wire Saw

>> Manual CE Approved Sumore Tool Industrial Drill Press Tapping Automatic Drilling Machine Factory

>> Export Sweet Fruit Fresh Delicious FUJI Apple with High Quality

>> High-quality expanded metal mesh for stairs or walkway

>> Extra Long Stainless Steel Rib Rack For Smoking and Grilling Fits 18" or Larger Gas Smoker/ Charcoal Grill

>> Small Size Pellet Broiler Feed Machine for Farming Plant

>> High Precision Automated Drilling Machine for Industrial Tapping Needs