Custom - Made High - Precision EPP & EPS Foam Mould

Basic Info.

Model NO.

customize

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

EPP

Process Combination Type

Compound Die

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

AutoCAD

Certification

TS16949, CE, ISO, FDA

Standard

PUNCH

Customized

Customized

After-sales Service

Yes

Transport Package

Wood

Specification

Customization

Trademark

Customized logo

Origin

China

HS Code

3901909000

Production Capacity

5000PCS/Year

Packaging & Delivery

Package Size

41.00cm * 59.00cm * 90.00cm

Package Gross Weight

15.000kg

Product Description

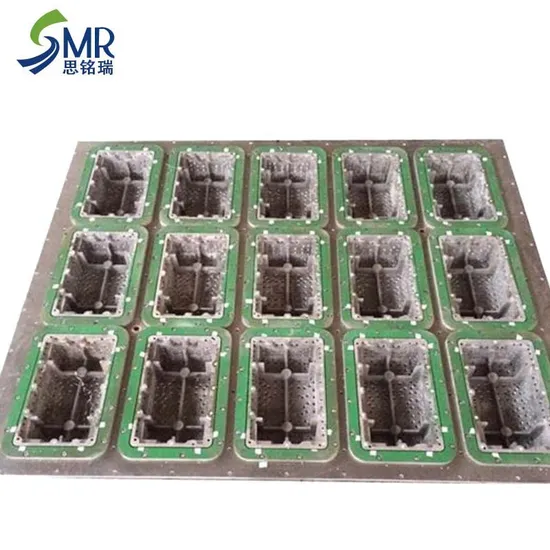

Custom - Made High - Precision EPP & EPS Foam MouldProduct Parameters

| Item | provide drawing and we will customized. | |

| EPP foam parts customized | accept | |

| EPS foam parts customzied | accept |

Product Description

Features of epp mould

1) EPP mould made of high-quality aluminum alloy

2) With a standard frame and cooling system

3) Covered with teflon to create non-stick surfaces, increase ejection ease and promote corrosion and heat resistance.

Scope of eps mould:

Our EPP/EPS/EPO foam moulding tools are intensively used for production of electronics packaging, technical equipment and instrument packaging, food and beverage thermal insulation packaging, transport packaging, medical equipment and devices, air conditioning structural foam parts, automotive components and interiors,

sport helmets and other protective gear, RC Hobby Model Planes, child toys, etc.

Our Advantages

1.17 years of experience in mold production.

2. One-stop OEM solution service.

3. The company has advanced equipment and strong technical force. At present, it has more than 30 sets of mold processing equipment such as CNC machining center and gantry milling, 10 professional mold design engineers and more than 50 professional mold technicians.

4. Quality control, strong production capacity and short delivery time.

5. Competitive prices.

>> OEM 12588100 Timing Tensioner for Chevrolet Colorado 2.9L TN5002

>> PVC Window Making Machine CNC Roll Bending Machine Aluminium Window Machinery

>> Single Layer Belt Reusable Washable Belt Polyester Woven Belt Forming Fabric Mesh Belt for Belt Pulp Washer

>> Customized Color Sir/FKM/EPDM/NBR Pipe Gasket Connector Rubber Parts

>> 54000bph 500ml Pet Bottle Blow-Moulding Machine China

>> GAPV For Toyota Camry Vios Auto Rear View Mirror Cover Untinged 2006-2011 Accessories 87915-06905

>> MSL238 Women Muslim Turban Lady Adjustable Hijab Islamic Stretch Elastic Head Cover

>> OEM Factory 100L 200L300L DC/AC Solar PV Water Heater with Enamel Coating Tank

>> Riflescope Protective Cover Sight Bag Anti Scratch

>> 7.5HP 4 Stroke 212cc Agricultural Gasoline / Petrol Power Tillers Garden Rotavator Gasoline / Petrol Rotary Cultivator Tiller with Cast-Iron Gearbox (GT800A-3)

>> High Quality Plastic Bucket Molding Machine Horizontal Barrel Moulding Injection Machine

>> Mud Pulser Parts Inlet Plate Carbide Rotor and Stator for Mwd Tools

>> CNC Laser Cutting Machine with Japan Panasonic Servo Motol

>> Carbon Fiber Outrigger Pole, 3K Custom 100% Carbon Fiber Pole

>> Specially custom logo designed kraft paper bags for reusable candy and biscuit sets Christmas gift boxes

>> 1113 Medical CT Room Lead Leg Pads, X Ray Foot Guard/ X-ray Radiation Protective Shoes Cover Lead Foot Protection

>> Quartz tube 2 rollers OEM 230 mm A4 Hotlaminator Office Laminating Machine Manual Table Pouch Laminator hot laminating machine

>> THERAPY MACHINE USED TO TREAT HEADACHE, PAIN RELIEF, AND INSOMNIA

>> byloo fishing store wholesale rod tip fishing rod 2. 70 m

>> High Viscsoity Butterfly Dissolver for Polyurethane Waterproofing Membranes 60000 Cps

>> exterior glass accordion door big glass aluminum folding door outside

>> Chemical LPG Liquid Transport Semi Trailer Fuel Tanker Petroleum Trailers for Sale

>> Wood-Working Edge Banding Machine for Wood Board Side Press and Glue Machine with Wood Belt with EVA Hot Melt for Particle Board Production Line Wood Polishing

>> 3.6 Cbm Mini Concrete Mixer Truck

>> Xz6350zb/Xz6350b/Xz6350g, Milling/Drilling Machine.

>> Customized Portable Inflatable Cold Plunge PVC Ice Bath Chiller Tub

>> Rvr-740K Reliable CNC Rotary Transfer Solution for Efficient Brass Valve Making Lathe Machine for Metal

>> Nordic Luxury Living Room Sofa Plush Cushion Imitation Rabbit Hair Throw Pillow

>> 12000lbs 4WD Winch for Jeep

>> 99.7% 3-25mm Pure Titanium Block Sponge Titanium