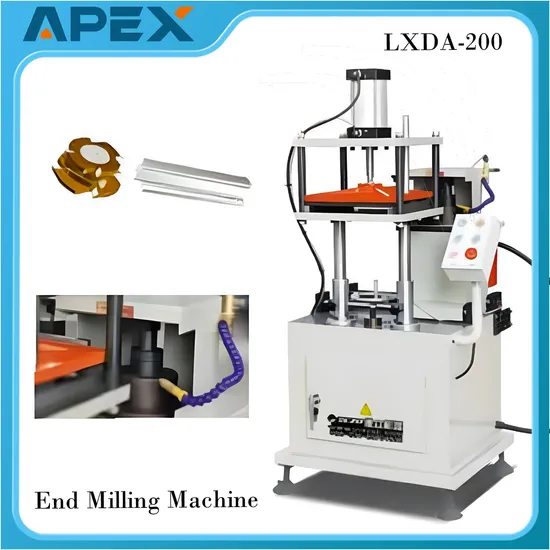

Lxda-200 End Milling Machine for Aluminum Profile End Milling, Step Face and Slotprocessing etc, at The Same Time Milling Multi-Piece Profiles

| US$1,100.00-1,400.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LXDA-200

Type

Meter Milling Machine

Object

Sheet

Structure

Gantry

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

CNC

Automatic Grade

Manual

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Lnput Power

1.5W

Power Supply

380V/50Hz

Working Pressure

0.5-0.8MPa

Motor Rotary Speed

2800r/Min

Motor Main Shaft Diameter

φ32mm

Cutter Adjustment

0~80mm

Milling Cutter Height

70mm

Diameter of Miling Cutter

φ110~φ200mm

Worktable Journey

0~320mm

Overall Dimension

850×740×1350mm

Weight

800kg

Transport Package

Wooden Packing

Specification

End Milling Machine

Trademark

APEX

Origin

China

HS Code

8459619000

Production Capacity

100000 Set/Year

Product Description

Technical Parameters

| Model | lnput power | Power supply | Air pressure | Motor rotary speed | Diameter of main shaft | Cutter adjustment | Milling cutter height | Diameter of miling cutter | Worktable journey | Overall dimension |

| LXD-200 | 1.5KW | 380V/50Hz | 0.5~0.8MPa | 2800r/min | φ32mm | 0~ 80mm | 70mm | φ110~φ200mm | 0~320mm | 850×740×1280mm |

| LXDA-200 | 1.5KW | 380V/50Hz | 0.5~0.8MPa | 2800r/min | φ32mm | 0 ~ 80mm | 70mm | φ110~φ200mm | 0~320mm | 850×740×1350mm |

LXDA-200 End Milling Machine

Used for aluminum profile end milling ,step face and slotprocessing etc,at the same time milling multi-piece profiles.

1.This machine is designed for tapping, routing and milling holes, lock holes, launder and other slots on the profiles of curtain walls. It can work on various profiles.

2. It adopts YASKAWA servo-motor and driver which are made in Japan.

3. It adopts high speed HSD spindle of Italy

4. It adopts HIWIN linear guide and YYC grinded gear racks result highly precise process.

5. It adopts computer control system, CAD-CAM software, which are used in industry area specially.

6. It adopts SEIMENS electrical & pneumatic products, solenoid valves, SMC gas resource processors and JPC air cylinders.

6. Revolving six position mills makes the mill-changing convenient.

7. Double profile locating devices, no need to stop the machine while taking the profiles on and off.

8. With half-close safeguard device to insure the personal safety of the operator.

Our Advantages

Product details and features

Production Process

Packaging & Shipping

Company Profile

After Sales Service

1.One year warranty time, we can repair and replace parts for free in one year.

2.Technical support in 24 hours online, TM, Skype, E-mail, solving the relative questions in time.

3.Life time free maintenance service.

4.Free training course at our factory with professional engineers.

5.We provide the consumable parts at agent price when you need replacement.

FAQ

1. Q: Are you a manufacturer or trading company?

A: Yes, we are a manufacturer.We are focusing on metal pipe/tube processing machines production.

2. Q:Where is the nearest airport to your company?

A: JINAN Airport.

3. Q: How to choose the pipe/tube bending machines?

A: You have to inform us following details:

- Pipe Outdiameter Range

- Wall thickness range

- Bending Radius Value

- The pipe material

- Bends Number on one pipe

- The drawings if possible

4. Q: What certificate do you have?

A: We have both ISO and CE certificate.

5. Q:How about your service?

A: Before Sales Serive:

1. We will help our customer confirm the right model according to the offered pipe inforamtion.

2. Welcome to visit our factory to see our machine and our workshop before you place an order.

>> 1kg/3kg/5kg Quad Seal Flat Bottom Animal Dog Cat Food Packaging Recycable Mono-PE Ecofriendly Degradable Disposable Bags

>> Intel I3/I5/I7/I9 4K60Hz OPS for Electronic Whiteboard for High-Performance Smart Classrooms OPS

>> 60t/H Roady Hzs60 Concrete Mixing Plant

>> 2L Laboratory Hotplate High Temperature Magnetic Stirrer with Heating

>> High Viscosity Mixing Stainless Steel MID-Batch Double Planetary Blender Mixer Machine

>> Special Color Metal Alloy Badge with Custom Logo for Garment Use

>> TM-8812 Ultrasonic Thickness Testing Ultrasonic Thickness Meter/Gauge Thickness Measurement

>> New design PLC controller plastic Color trays plastic recycling granulator machine for Injection and Extrusion

>> Factory Price Wheat Reaper Binder Machine 4 Wheels Riding Type Paddy Rice Reaper Binder Machine

>> Rugged 8" Biometric Tablet with Fingerprint and Card Reader for ID Enrollment

>> Adhesive Packing Aluminum Collapsible Tubes for Super Glue

>> Electric Laboratory Printing Machine

>> 1617 12/24hour clock luminous fitness tracker watch skmei military digital watch instructions

>> Prima 250t3200mm Nc Press Brake E21 with High Quality

>> K4-1000DSP Professional Audio 4 Channel Class D 1000 Watts DSP Power Amplifier

>> OEM Hexagonal Shape Stainless Steel 304 Perforated panel sheet in Anping

>> Dialead Solid Bar Copying Machine

>> Custom Magnetic Fridge Notepad to Do List Note Pad Memo Pad Pocket Pad Daily Planner Pad Sticky Notepads Tear off Pattern Pad

>> 316 Stainless Steel D-Type Shackle Marine Shackle Connection Ring Marine Straight Shackle

>> Aluminium Brass Metal Parts Continuous Sheet Metal Stamping Die Manufacturer

>> Computerized panel Automatic Mattress Fabric Cutting Machine

>> TPU PU PVC Steel Wire Reinforced Air Duct Hose Production Line Extrusion Machine

>> Fat Reduce DUAL CAVITATION VACUUM Vela Slimming Machine For Body Shaping

>> New Turning Machinery Universal Precision Lathe Machine Lh6251*3000mm

>> Car Disc Brake Lathe Machine Brake Drum Disc Lathe C9372

>> Auto Tool Change High Speed Engraving Machine CNC Router 1325 3 Axis for Furniture Wood Door Making Advertising Woodworking Acrylic Aluminum Cutting Machine

>> Liqiang- Multi 14 Wires Drawing Machine with Annealer Online

>> SMS SSS Spunbond Non-Woven 100 PP Supplier Raw Material for Diapers

>> Feed Additive Vitamin a Acetate Powder 500 Feed Grade Vitamin Va

>> Sea Transportation Laser Cutting Machine for Pipes with Profiles and Special-Shaped Tubes