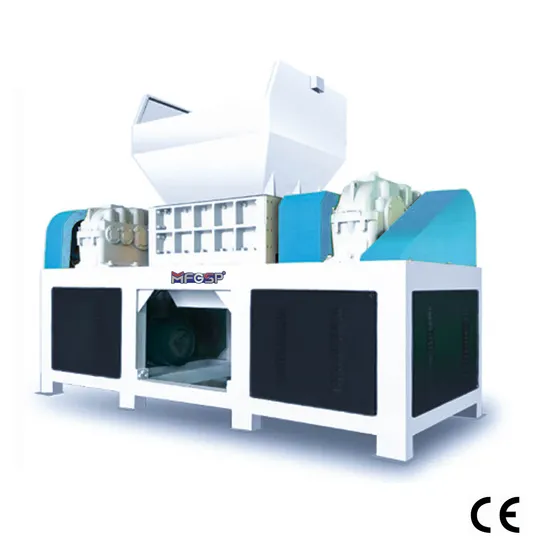

Superior Plastic Shredding Crushing for Injection Molding Machine Manufacturer High Performance Double Shaft Shredder

| US$6,350.00-9,680.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SPS500-1

Material Processed

Plastic

Plastic Type

PP,PE,ABS,PVC etc.

Screw

Double-Screw

Automation

Automation

Computerized

Non-Computerized

Certification

ISO9001:2008, CE

Motor Power(kw)

5.5x2

Electric control

PLC overload automatic reverse

Reducer

K87x2

Speed(r/min)

17

Blades Diameter(mm)

200

Blades Thickness(mm)

15-25

Feeding Diameter(mm)

850x700

Blades Box Diameter(mm)

510x400

Transport Package

Standard Export Packaging

Specification

1900x750x1700mm

Trademark

MFGSP

Origin

China

HS Code

8477209000

Production Capacity

5000sets/Year

Packaging & Delivery

Package Size

200.00cm * 85.00cm * 80.00cm

Package Gross Weight

5140.000kg

Product Description

Double shaft shredder

Performance characteristic:

Multifunctional shredder is also called double-shaft shredder,which specializes in handling waste cars,waste tires,electronic waste,wooden pallet,waste household appliances and furniture,etc.The geometry of the blade can be customized according to the specific materials to be processed. Two reverse rotating shafts with specially designed blades and a spacer comb placed between the blades and connected to the wall of the shredded chamber vigorously cut the material into pieces.

Product introduction:

This series of double shaft shredders can meet the waste recycling requirements of various industries, and is suitable for shredding thick and hard to break materials such as electronic waste, plastic, metal, wood, waste rubber, packaging barrels, pallets, etc.

There are many kinds of recyclable materials, and the shredded materials can be recycled directly or further refined according to demand.

It is applicable to industrial waste recycling, medical recycling, electronic manufacturing, pallet manufacturing, wood processing, domestic waste recycling, plastic recycling, tire recycling, papermaking and other industries.

Scope of application:

Fully automatic production line

Detailed description:

| Reinforced case, smooth and flat inner cavity, tenon structure, easy to disassemble | |

| The intelligent control system monitors the whole operation process of the equipment in real time to ensure the safety of the tool | |

| The gearbox of the shredder adopts a hard gear reducer with high precision and long service life | |

| The shredder blade is made of alloy steel after forging, fine grinding, annealing, heat treatment and tempering |

Combined Type:

Blades with different hooks:

| Single-hook blade | Two-hook blade | Four-hook blade | Six-hook blade |

| Hooks type | Application characteristics | ||||||

| Single-hook blade | Single hook blade configuration is the most universal blade choice.It has a powerful structure and can be used in a wide range of applications. | ||||||

| Two-hook or Multi-hook blade | Multi hook blade configuration is used primarily for shredding easy to shred products.It is more efficient when doing light shredding applications. | ||||||

Blades with different thickness:

·10mm-20mm blade is suitable for thin and fragile products, such as medical supplies and circuit boards

·40mm-50mm thick knife is used for general products, such as plastic products, films, plastic buckets, tires, wood boards, etc

·The blade with a thickness of more than 75mm is suitable for thicker plastic or plastic and metal composite products, such as refrigerators, metal cans, and other products with a metal thickness of less than 100MM

Technical parameter:

| Model | SPS200 | SPS300 | SPS400 | SPS500 | SPS500-1 | SPS600 |

| Motor Power(kw) | 1.5 | 3 | 4 | 7.5 | 5.5x2 | 7.5x2 |

| Electric control | Overload shutdown | Overload shutdown | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse |

| Reducer | RV90 | KA77 | K87 | K97 | K87x2 | K97x2 |

| Speed(r/min) | 15 | 16 | 14 | 15 | 17 | 15 |

| Blades Diameter(mm) | 158 | 180 | 180 | 200 | 200 | 220 |

| Blades Thickness(mm) | 8-12 | 10-15 | 12-20 | 15-25 | 15-25 | 20-30 |

| Feeding Diameter(mm) | 350x450 | 650x550 | 700x650 | 850x700 | 850x700 | 900x700 |

| Blades Box Diameter(mm) | 210x300 | 310x370 | 410x370 | 510x400 | 510x400 | 610x450 |

| Overall dimension L*W*H(mm) | 600x600x1200 | 850x700x1200 | 1150x700x1400 | 1350x750x1700 | 1900x750x1700 | 2000x800x1800 |

| Scope of application | Plastic products, food packaging, electronic waste, kitchen waste, fiberboard, confidential destruction, etc | |||||

| Model | SPS1400 | SPS1600 | SPS1800 | SPS1800-1 | SPS2000 | SPS2600 |

| Motor Power(kw) | 55x2 | 75x2 | 90x2 | 110x2 | 132x2 | 220x2 |

| Electric control | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse | PLC overload automatic reverse |

| Reducer | Planetary ReducerTP12 | Planetary ReducerTP13 | Planetary ReducerTP14 | Planetary ReducerTP16 | Planetary ReducerTP18 | Planetary ReducerTP20 |

| Speed(r/min) | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 |

| Blades Diameter(mm) | 500 | 550 | 600 | 650 | 700 | 800 |

| Blades Thickness(mm) | 60-90 | 80-100 | 90-120 | 100-140 | 100-150 | 100-180 |

| Blades Box Diameter(mm) | 4120x1000 | 1620x1100 | 1820x1200 | 2020x1300 | 2020x1400 | 2600x1600 |

| Scope of application | Decoration waste, industrial solid waste, hazardous waste, large oil drums, trays, large pieces of garbage, refrigerators, tires, car shells, etc | |||||

>> Hot Selling High Frequency Textile Emboss Machine For Garment Embossing

>> Auto Grill stainless steel expanded metal Grille

>> Good Quality Injection Molding Machine for Plastic Flower Pot

>> Soft Black Slatted Metal Frame Foldable Multi XL Twin Size Bed for Kids

>> High Quality Home Bedding Set 3PCS Quilt Cover Jacquard Bedding Set Cotton Bed Sets

>> JIMBO wholesale coffre fort caja fuerte digital steel security drop cash deposit money storage depository safe

>> High-Quality K Serious Sk8 Variable Pitch Blow Molding Machine

>> Low Price Small Roll Paper Cutting Machine with Embossing

>> Conveyor Roller/Idler Making Machine of Automatic ISO Shaft Both Ends Flat Slot Milling Machine

>> Efficient and Energy-Saving Pre Formed Mold Cleaning Solution Mineral Water Bottle Injection Molding Machine

>> Cbb61 Air Conditioner Capacitor 5-75UF Blowers and Washing Machine

>> DC-2880mm High Strength Kraft Liner Paper Corrugated Paper Fluting Paper Making Machine

>> Taijia tm8811 portable thickness gauge steel ultrasonic metal ultrasonic thickness gauge ultrasonic steel thickness gauge

>> Upgrade to full LED laser headlamp headlight plug and play for BMW 7 series G11 G12 head lamp head light 2016-2019

>> Export Children′s Toys Products to Nigeria for Soncap Certification Processing

>> Straight Blade Magnetic Sharpener, High Precision Strong Grinding Machine, Straight Knife Grinder for Industrial Knife Blades

>> Factory Automatic Circular Loom Plastic Sack PP Woven Bag Making Machine

>> 304ss Manifolds for Water Pump System (YZF-E202)

>> FRP Hood for BMW 3 Series F30 Hood also for BMW 4 Series F32 Bonnet for BMW F32 Hood 2012-2016 Year

>> Eglobal Rugged Embedeed Mini PC Intel Core I3 I5 I7 Win10 PRO Win11 2LAN 6COM Mini Computer Industrial PC for Medical Equipment

>> GAPV Headlamp For toyota crown 2010 years 81145-0N070 right side withe color

>> High Productivity PLC Crochet Machine

>> Outdoor Waterproof Recessed Arc Solar Street Aluminium Profile Led Lamp Housing

>> CNC Machine CNC Deep Hole Drilling Machine for Stainless Steel

>> Hot Sell Custom 1/32 Scale Model Car Wholesale Alloy Die Cast Transformation Pull Back Car Realistic Metal Truck Toy Promotional Vehicle Car with Open Door

>> Ca 360 Brass Compression Union Tubing Female Connector Fitting

>> Rainbow Bear Kid Outdoor Climb Mountain Children Anti-Slip Shoe

>> Shanghai Ganglu Huinong Biotechnology Veterinary Medicine Feed Additives Multivitamin Water Soluble Powder for Chickens Poultry

>> high quality low price mosquito net roll screen product supplier

>> Baby Safe Plastic Cotton Buds Big Head Cotton Swab for Baby Health Sample Customization