Large Beer Brewery Equipment 3000L Brewery Equipment Beer Brewing Machine for Sale

| US$80,000.00-200,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

MT-3000L

Processing Material

Water, Malt, Hops, Yeast

Application

Beer

Customized

Customized

Certification

CE, ISO9001

Power Source

Electric

Automatic Grade

Semi-Automatic

Material

SUS304 Stainless Steel

Cooling System

Dimple Plate Jacket

Control System

PLC/Himi/Touch Screen

Thickness

Inner:3-4mm, Exteior:2mm

Voltage

220V/380V/440V/Adjustable

Capacity

3000-5000L

Ddimension(L*W*H)

Depending on Capacity

Weight

Depending on Capacity

Welding

Bothe Sides TIG Welding

Transport Package

Plastic Film, Plywood Case; Container;

Specification

User Requirements

Trademark

METO

Origin

Shandong, China

HS Code

84384000

Production Capacity

10 Set/Sets Per Month Stainless Steel Brewhouse

Packaging & Delivery

Package Size

200.00cm * 200.00cm * 200.00cm

Package Gross Weight

20000.000kg

Product Description

Large Beer Brewery Equipment 3000L Brewery Equipment Beer Brewing Machine for SaleProducts Description

Commercial brewery equipment is designed to produce beer on a larger scale than microbrewery equipment. It is designed

to optimize efficiency, consistency, and productivity while maintaining quality standards in beer production. The equipment

is often modular and scalable to meet the production volumes and specific needs of each brewery.

Capacity:

Volume of wort per batch 20HL - 100HL

| Wort / Brew | 20HL | 25HL | 30HL | 50HL | 100HL |

| Bach / Day | 2-8 | 2-8 | 2-8 | 2-8 | 2-8 |

| Output / Year | 1200KL-4800KL | 1500KL -6000KL | 1800KL - 7200KL | 3000KL-12000KL | 6000KL-24000KL |

| Brewhouse Combination | 4 Vessels: Mash tun + Lauter Tun + Boiling Kettle + Whirlpool Tank 5 Vessels: Mash Tun +Prerun Tank + Lauter Tun + Boiling Kettle + Whirlpool Tank Other combinations can be customized on request | ||||

| Brewery Area Request | >800M² | >1000M² | >1000M² | >1500M² | >2500M² |

| Degree of Automation | Full Automatic | Full Automatic | Full Automatic | Full Automatic | Full Automatic |

| Brewmaster | 1-2 | 1-2 | 1-2 | 2-3 | 2-3 |

VR

Product advantages

1. Customized design tailored to meet customer's product specifications

2. Utilization of top-notch processing equipment and high-caliber production personnel

3. Utilization of stainless steel plates, pump valves, and other accessories sourced from reputable manufacturers

4. Consistent, dependable, and efficient automation control

5. Sleek and sophisticated appearance design with user-friendly operational layout

6. Proven success with numerous domestic brewing industry leaders

7. Exceptional after-sales support

8. Energy-efficient operations to enhance product competitiveness

9. Comprehensive consultation services for beer plant design

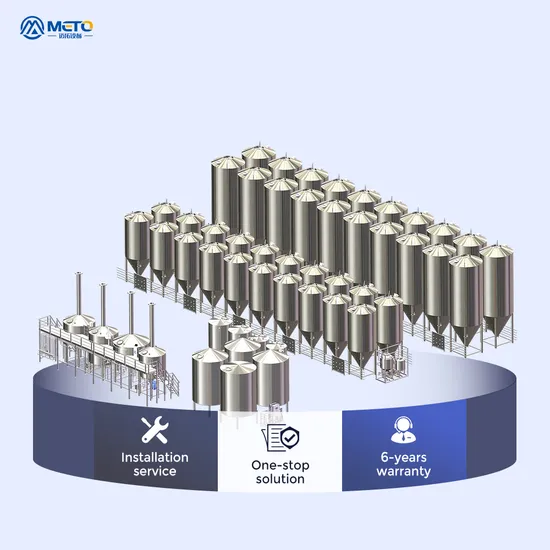

eto offer one-stop turnkey projects. Our commercial brewing equipment are available with several options to help deliver

brewingefficiency, control & automation, and overall flexibility. The brewery combines our engineering expertise and

experience withprecision manufacturing techniques. All systems are expandable and fully customizable based on your

requirements.

Commercial Brewery Equipment Component

| Malt Milling Unit | Malt Miller |

| Stainless Steel Conveying | |

| Pipe Chain Conveyor | |

| Grist Hydrator | |

| Dusty Collector | |

| Grist Silo | |

| Brewhouse Unit | 3 vessels ,4 vessels ,5 vessels |

| Fermentation Unit | 20HL -1000HL |

| Water Tank Unit | Hot Water Tank |

| Cold Water Tank | |

| Ro Water Tank | |

| Hot Water Pump | |

| Cold/ Ro Water Pump | |

| Water Pipe | |

| Cooling Unit | Glycol Water Tank |

| Chiller | |

| Cooling Pipe And Pump | |

| Cip Unit | Hot Alkali Tank |

| Acid Tank | |

| Sterile Water Tank | |

| Hot Water Tank | |

| Liquid Transfer | |

| Brewery Control Unit | Brewery Automatic Control System |

| Brewery Pipeline Gallery Unit | Wort Pipeline |

| Beer Pipeline | |

| Cip Pipeline | |

| Co2 Pipeline | |

| Air Compressor Pipeline | |

| Sewage Pipeline | |

| Outdoor Exhaust Pipeline | |

| Steam Pipeline | |

| Square Tube Bracket | |

| Other Auxiliary System | Steam Boiler |

| Ro Water Treatment System | |

| Oil-Free Air Compressor System | |

| Yeast Propagation Unit | |

| Hop Gun | |

| Centrifugal Filter Machine | |

| Beer Instant Sterilizer Machine | |

| Tube Heat Exchangers | |

| Beer Packing Unit Filling | Keg Filling Machine |

| Keg Washing Machine | |

| Bottles Filling Line | |

| Beer Canning Line |

Company Profile

Packaging & Shipping

Product packaging

>> Xiantao Factory Supply High Quality Hotsale Disposable Nonwoven PP SMS Isolation Gown with Knit/Elastic Cuff

>> 220V-240V Main Hardwired Interconnected Smoke Alarm with 10 Years Battery Backup

>> Black PVC Coated Solar Panel Bird Control for Bird Protection Mesh

>> Milling Cutter Grinder Grinder Milling Machine

>> Hose Bottom Loading Arm with API Dry Break Coupler

>> Custom OEM New Design Men Tank Top Plain Color Men Tank Top Wholesale Price Men Tank Top Manufacturer

>> Fast Speed Electric Motorcycle with Powerful Motor

>> Rechargeable Soft Multifunctional LED Camping Lantern Light for Outdoor Camping

>> Shredder Tire Tread Cutting Recycling Machine Waste Tire Tread Cutting Processing Machinery

>> Double glass thermal break low u value sliding sash windows for villa

>> Proshot Aqua Dome 127 - K9 & Bk7 Glass Underwater Lens Dome for Professional-Quality Shots

>> Polyphosphoric Acids CAS: 8017-16-1 Used as an Analytical Reagent, Cyclizing Agent and Acylating Agent

>> Hg260p Gpon Epon Zte Chip Set Xpon ONU 1ge 3fe 1tel + 2.4G/5g FTTH Ont AC WiFi

>> Efficient Open Cam System Paper Cup Making Equipment

>> Inflatable Jump Air Bag for Ski Snowboard Skate

>> 2021 commercial garlic onion huller peeling machine

>> Cheap and Safe Logistics Companies for Sea and Air Freight, Shipping Companies, UPS, DHL, FedEx, TNT International Logistics, From China to Japan Shipping

>> TR413C TR414C TR415C TR418C sleeved car rubber nozzle Universal chrome plated car tyre valve

>> Ensign Manufacturer Sell 40HP Tractors with Harrow

>> Simple Titanium Steel Couple Pair Ring Electroplating Gold Inlaid Zircon Jewelry

>> Efficient and Energy-Saving Plastic Waste Film Agglomerator Machine

>> 1PCS 18V Power Tools Power Drill 18V Rechargeable Lithium Battery Impact Cordless Drill

>> Rotating Worktable for Grinding Rooftop Tools Sharpening Punch Press Tooling

>> Creative Metal Iron Tower Shape Essential Oil Wax Heater Candle Warmer Burner

>> Feed Milling Machine Automatic Fish Feed Line for Animal Poultry Chicken Feed Pellet Production Line

>> 1ton 2ton 3ton Excavator CE/EPA Approved Good Condition Excavator Construction Machinery

>> Quay Pneumatic Rubber Fender Rubber Floating Dock Fender

>> Taijia Transit-time ultrasonic flow meter ultrasonic flowmeter sensor portable

>> Good Quality Solid Bamboo Panel Furiture Dining Table Set / Coffee Table Set

>> Hot Selling Self Propelled Articulated Boom Lift Pallet Stacker Electric for Warehouse Working