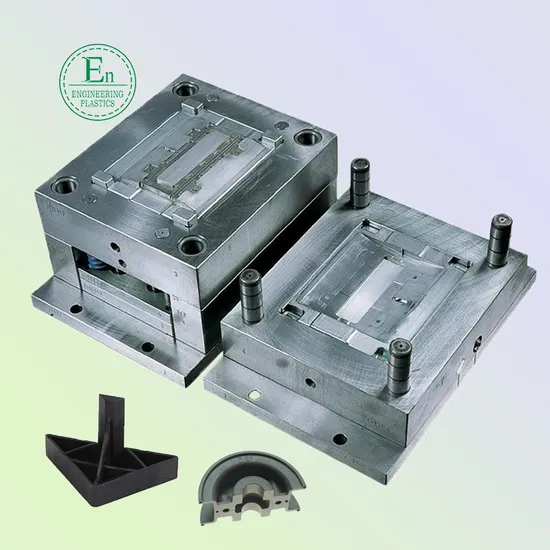

Molding Die Single Process Mode Injection Mould Manufacturer Custom Automobile Spare Parts Plastic Mold

| US$3.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

Aut Service Plastic Molding Parts

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

Plastic

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

Custom

Color

Custom

Transport Package

Boxs

Specification

custom

Trademark

gz-plastic

Origin

China

Production Capacity

5000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 40.00cm * 50.00cm

Package Gross Weight

10.000kg

Product Description

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material.We can provide you with one-stop solutions.Main Product: 1.Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) . 2.Engineering plastics products Processing: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

How to get a quotation: 1. Prepare a picture or 3D drawings; 2. You want the products material;

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine (Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"! Science and technology will change the future! Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service! |

| Shipping status notification during delivery! | |

| Regular notification of new styles & hot selling styles! |

The production process of injection mold refers to the process of melting plastic raw materials by heating, then injecting them into the mold, cooling and solidification, and finally obtaining the required molding products. Injection mold production process mainly includes the following steps:

1. Pretreatment of plastic raw materials: including drying, mixing, adding color and other processing to ensure the quality and stability of plastic raw materials.

2. Mold design and manufacturing: according to the shape, size, material and other requirements of the required molding products, design the corresponding mold and manufacture.

3. Injection molding: the pre-treated plastic raw materials are heated and melted, and then injected into the mold, and after cooling and solidification, the required molding product is finally obtained.

4. Finished product treatment: including slag removal, trimming, grinding, painting and other treatments to improve the quality and beauty of the finished product.

Certifications

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application

Our Factory

Our Exhibition

Cooperative Case

>> Outdoor Sport Game Inflatable Palm Slide for Children

>> Customization New Trendy Good Quality 30s 140GSM Rayon Printed Floral

>> Em slimming sculpt machine electromagnetic field muscle stimulation

>> CNC Gantry Milling Double Column Machining Center XH3022 XH4022 XH5022

>> 200W LED COB PAR Can Stage Light 4X50W Warm Cool White LED COB Blinder Stage Light LED Wash

>> Hsy128 Mattress Production Line Industrial Automatic Fabric Sewing Textile Shuttle Multi Needle Single Quilting Machine

>> Agrieso 3000K 9W 220V Waterproof Flicker Free Dimmable Poultry Layer Lighting Bulb

>> Customized O Shaped Plastic Parts PTFE Bushing Ring Gasket Virgin PTFE Rings

>> High Efficiency Food Composting Machine Turn Food Into Compost Agricultural Machinery

>> high frequency welder 15khz 2600W good price ultrasonic welding machine equipment for plastic pvc welding

>> China Manufacturer Waterproof Click Locking Spc Vinyl Flooring

>> SGS Brc Factory China Wholesale Transparent PP Woven Fabric /Tubular Woven Fabric/Coating Fabric / Polypropylene Woven Tubular Fabric for Bigbag

>> Soft Stretch Mesh Trim for Lingerie with Comfort

>> 2021 most popular Equinox car Headlight (middle match) RH For Chevrolet 84428290 84258432 84319834 84423830 84194546

>> 2022 Factory Price New 2L zeolite eco Indoor Electric Portable Dehumidifier For Home air purify ionizer

>> Youngparts 2024 New 10 Inch Extension Spiral 1/2-28 5/8-24 Single Core Car Alloy Fuel Filter Solvent Trap for Napa 4003 Wix 24003

>> Taijia ZD410 Integrated Nonmetallic Board Thickness Tester thickness gauge

>> MR-J2S-60A Mitsubishi Electronic AC Servo Driver Frequency Converter

>> Full Automatic High Speed Linear Blow Moulding Machine Non Stop Heating Mineral Water Bottle Blower

>> Large Size Hot Air Seam Sealing Machine for Waterproof Products Car Cover

>> Versatile 50-5000L Industrial Shampoo and Shower Gel Mixer

>> Fiber Laser Welding Machine Welding Tools for All Metals

>> Brand New Mini Nc Hydraulic Press Brake Wc67y 160 3200

>> Precision Screen Exposure Machine for Screen Printing

>> Bernard Smart Module actuator accessories B+RS forward and reverse drive

>> Sinotech Desktop Small Injection Molding Machine for Plastic Snap Button Manufacture Making Machines

>> Hot Sale Small Size 3D Wax Printer for Gold Silver Jewelry 3D Wax Printer Machine for Jewelry Resin Dental Rapid Prototyping

>> Laser Sword Lightsaber Telescopic 2 Colors Electronic Flashing Sword Gifts Whosale Toys

>> Factory Customized Electric Heating Car/Truck Spray Booth Paint Booths with Discount

>> Concrete Truck with Concrete Pump with Best Price