Factory Direct Sale Turret Milling Machine Manual Milling Machine for Parts Processing Machine Used Widely

Basic Info.

Type

Worktable Milling Machine

Object

Gear

Structure

Bed type

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Manual

Precision

Precision

Certification

CE, ISO 9001

Condition

New

Longitudinal Stroke of Table(mm)

350

Lifting Stroke of Table(mm)

350

Table Feeding Steps

8(Eight Steps)

Table Longitudinal and Lifting Feed Rang

F25-285mm/Min

Table Speed of Vertical and Vertical Rap

1000mm/Min

Number of T-Slot

6

Width of T-Slot(mm)

14

Distance of T-Slot(mm)

45

Table Size(Longxwide)(mm)

750X260

Spindle Taper of X8126

7:24 Is040

Lateral Movement Stroke of Spindle (mm)

200

Travel Per Revolution of The Dial(mm)

1.5

Spindle Speed Steps

8

Spindle Speed Range

110-1230r/Min

Spindle Feeding Steps

8

Transport Package

Wood Box

Specification

1450x1445x1650mm

Trademark

Vedon

Origin

Tengzhou City, Shandong Province, China

HS Code

8459290000

Production Capacity

100-500sets/Year

Product Description

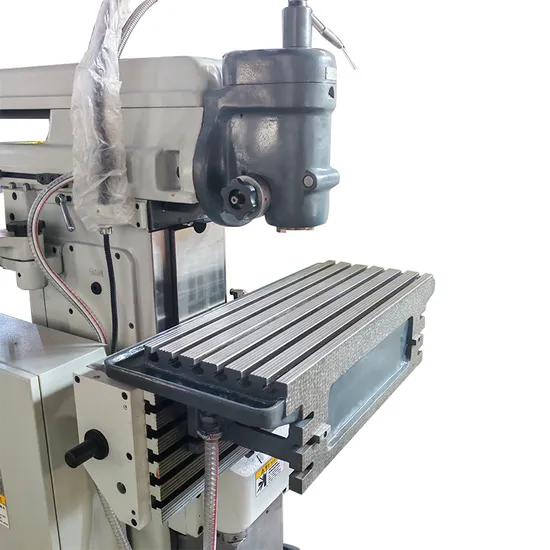

OverviewX8126 Universal milling machine

X8126 universal milling machine can complete boring, milling, drilling, inserting and other cutting processing, suitable for processing a variety of tools, fixtures, die, die and other mechanical products manufacturing and processing, medium and small molds and other complex parts, with a variety of special accessories can complete arc, rack, gear, spline and other parts processing. Machine tool accessories are: vertical milling head, dividing head, disk table, Angle table and vice, so strong function, wide use.

1,Novel structure, wide versatility, high precision, easy to operate.

2,The use of a variety of accessories, can expand the scope of use, improve the utilization rate.

3,X8126: equipped with programmable digital display system, wide grid ruler resolution is 0.01mm.

Matters Needing Attention:

1,Loading and unloading parts, must remove the tool, cutting head, hand must not be close to the milling surface.

2,When using the milling machine to the knife, it must be slow or hand into, no fast forward, no stopping when walking the knife.

3,Fast advance and retreat knife pay attention to whether the milling machine handle will hit people.

4,Feed not too fast, no sudden change, milling machine limit block should be adjusted.

5,Up and down and measuring the workpiece, adjusting the tool, fastening the speed, must stop the milling machine.

6,Disassemble the end mill, the working table should be covered with wood, disassemble the milling cutter nut, the force should not be too strong.

7,Do not touch or use cotton yarn to wipe the rotating parts and tools, do not use the hand to support the cutter.

Product Parameters

| (X8126A Technical Parameters) | |

| Item | Details |

| Distance from horizontal spindle centerline to table surface | First installation position35-385mm Second installation position42-392mm Third installation position132-482mm |

| Longitudinal stroke of table(mm) | 350 |

| Lifting stroke of table(mm) | 350 |

| Table feeding steps | 8(Eight steps) |

| Table longitudinal and lifting feed range | 25-285mm/min |

| Table speed of vertical and vertical rapid movement | 1000mm/min |

| Number of T-slot | 6 |

| Width of T-slot(mm) | 14 |

| Distance of T-slot(mm) | 45 |

| Table size(longxwide)(mm) | 750x260 |

| Number of T-slot | 5 |

| Width of T-slot (mm) | 14 |

| Distance ofT-slot(mm) | 45 |

| Spindle taper of X8126A | 7:24 IS040 |

| Lateral movement stroke of spindle (mm) | 200 |

| Travel per revolution of the dial(mm) | 1.5 |

| Spindle speed steps | 8 |

| Spindle speed range | 110-1230r/min |

| Spindle feeding steps | 8 |

| Spindle feed range | 25-285mm/min |

| Spindle taper | 7:24 IS040 |

| Manual axial movement of the spindle (mm) | 80 |

| The movement of each grid on the dial(mm) | 0.5 |

| Spindle body rotation angle | -45 |

| Spindle speed level | 8 |

| Spindle speed range | 150-1660r/min |

| Distance from the centerline of the horizontal spindle to the lower plane of the upper beam(mm) | 96 |

| Distance fromthe front edge of the horizontal tableand thefront plane of the vertical guide rail of the bed due todifferent installation positions(mm) | 212-412 |

| Distance between the centerline of the vertical spindle andthe front plane of the vertical guide rail of the bed(mm) | 155 |

| Distance between the lower end face of the vertical spindleand the plane on the horizontal table(mm) | 0-285 |

| Total power capacity(kVA) | 4 |

| Main motor power(kw) | 3 |

| Main motor speed(r/min) | 1430 |

| Cooling water pump motor(w) | 40 |

| Machine tool dimensions(longxwide xhigh)(mm) | 1450x1445x1650 |

Machine Details

Company Profile

Shandong Vedon Intelligent Equipment Co., Ltd., We Specialize In The Design And Manufacturing Of High-Precision Cnc Machines For Metalwork Processing. Including 5 Axis Machining Center, Gantry Type Machining Center, Horitonal Type Machining Center, Vertical Machining Center, Cnc Lathe Etc.. With A Strong Focus On Innovation, Quality, And Reliability, Our Advanced Cnc Equipment Enables Precision And Efficiency In Every Application. Whether For Small-Scale Operations Or Large Industrial Projects, We Deliver State-Of-The-Art Solutions Tailored To Meet The Diverse Needs Of The Metalworking Industry. Powered By Cutting-Edge Technology And A Commitment To Excellence, We Are Dedicated To Enhancing Productivity And Driving Success For Our Global Clients.

Certifications

FAQ

Q1. Could I put my LOGO on it or paint my own color?

A: Yes, As long as the order quantity reach to the MOQ.

Q2. What's your trade terms?

A: FOB, CIF, DAP or other terms are acceptable.

Q3. Could I order trail small order?

A: Yes,we have no MOQ for standard version products. The price is different from different order quantity.

Q4. What points need to be confirmed before placing the order?

A: Voltage, frequency, plug type trade term and have shipping agent or not.

Q5. What is your terms of payment ?

A: Payment≤1000USD, 100% in advance. Payment≥1000USD, 30% T/T in advance, 70% before shippment. If you have another question, pls feel free to contact us as below.

>> Easy Operating Tk-Pm300 Mini Handhold Fiber Optic Powermeter

>> Sodium Pyrosulfite for Sale: Essential for Flotation in Mining

>> Qdwl Electric Motor 60 Cubic Meters Trailer Concrete Pump for Sale

>> CE 38mm 45mm 50mm Small Concrete Vibrator with Good Price

>> Supplying Automatic Down Feather Quilt Comforter Filling Machine

>> 2kg Nitrous Oxide Gas Cylinder Gas Filled Cream Charger Kitchen Tools Whip Cream Chargers Nitrous Oxide

>> Shacman Automobile Garbage Compaction Truck Compacted Garbage Transfer Truck Garbage Compaction Collection Truck

>> Safety Building Glass /Laminated Glass/Tempered-Laminated/Float Glass for Construction with Ce/ISO/SGS

>> GF36 CNC Steel Bending Machine Iron Rebar Stirrup Bender Hoop Machine 36mm 380V Steel Bar Bending Machine

>> Cooray Crl200msye Power Turret Slant Bed Twin Spindle Y Axis Turret Syntec CNC Turning Milling Compound Machining Center Lathe

>> Brand New Aftermarket Front Bumper Lower Grille for ML GLE W166

>> MAICTOP car auto accessories good price roof rack roof rail for land cruiser 2022 lc300 fj300 luggage rack

>> Madly style body kit for Porsche Cayenne 958 body kits for Cayenne 958 body kit 2011-2014 Year

>> Parallel Paper Tube Forming Machine Parallel Paper Tube Winding Making Rolling Machine

>> Original Samsung Evo Plus Memory Card 128GB 256GB Micro TF Flash SD Card 512GB 64GB up to 160m/S C10 for Phone Drones Camera DVR

>> Yong Chong Cao Bulk Price Nature Cordyceps Flowers Dried Cordyceps Militaris Mushroom

>> CS Home Morden Indoor Furniture Home Hotel Restaurant Patio Garden Sets Dining Table Set Ash Wood Chair

>> Timing Chain Systems Guide Kit TK1001-29 for Opel OE 5636360 5636453

>> SGA3060AHD full auto hydraulic metal polishing machine

>> High Speed Mixing System for PVC Resin Powder (SHR)

>> Factory Highlight 350 Lumens Waterproof USB Rechargeable Helmet LED Headlamp Camping Head Lamp

>> Poplin 100%Cotton Embroidery Cotton Lace Fabric for Dresses

>> Mobile Hydraulic Single Post Car Lift Machine # V-JZD-A-1527

>> Stylish and Efficient Barbecue Oven for Backyard Feasts

>> Tungsten Carbide Sizing Balls for 0.3440" Guides with Good Durability and High Precision

>> 60W 100W 200W 300W Solar Wall Street Lamp CE RoHS LED Lights Lighting Decoration Energy Saving Power System Home Products Sensor Security Garden Light

>> Junior Diving Mask Snorkeling Face Mask for Swimming Scuba Silicone PVC Tempering Glass Lens

>> big capacity electrical fresh sweet corn shelling machine for sale

>> Thermoforming Plastic PP PS HIPS PET ABS Sheet Extrusion Production Line Extruder Machine Plastic Container Extruder Machinery

>> Manufacturer Price Perforated Sheet Aluminum Hexagonal Hole Sheet Perforated Metal Mesh