CNC Gear Worm Thread Grinding Machine Tool Lathe for Hobbing Hob Turning Milling Spline Relieving Crankshaft Sharpening Metal Cutting 5 Axis

Basic Info.

Model NO.

CNC Gear Worm Thread Grinding Machine

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools, -

Movement Method

Contour Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

DIN3968 AAA

Certification

ISO 9001

Condition

New

Transport Package

Wooden Case

Trademark

EP

Origin

China

HS Code

8458110090

Production Capacity

500PCS/Month

Packaging & Delivery

Package Size

200.00cm * 180.00cm * 150.00cm

Package Gross Weight

1500.000kg

Product Description

CNC Gear Worm Thread Grinding Machine Tool Lathe for Hobbing Hob Turning Milling Spline Relieving Crankshaft Sharpening Metal Cutting 5 axisProduct Parameters

| | WGM-750 | WGM-550 |

| Center Height | 250mm | 175mm |

| Center Distance | 750mm | 550mm |

| Worm Diameter | Φ200mm | Φ150mm |

| Maximum Effective Length | 550mm | 450mm |

| Maximum modulus | M8 (unilateral grinding can reach M12) | M6 |

| Worm Type | ZA,ZN,Zl,ZK,ZC1 | ZA,ZN,Zl,ZK,ZC1 |

| Heads | Any | Any |

| Lead Angle | ±45° | ±45° |

| Max.Grind Depth | 20mm | 20mm |

| Accuracy | DIN3974 Teeth&Helix Level 4 | DIN3974 Teeth&Helix Level 4 |

| Table Transverse Strokt | Z=770mm | Z=600mm |

| WheelLongitudinal Stroke | X = 370mm | X = 300mm |

| Grinding Spindle | 25kw, Max.4500rpm | 27kw, Max.4500rpm |

| Max.Wheel | Φ500xΦ203x40mm | Φ400xΦ160x40mm |

| CNC System | LYNUC U5E | LYNUC U5E |

| Power | 3AC 380V 40KVA | 3AC 380V 40KVA |

| Main Machine Size | 3150x2100x1900mm | 2825x2100x1900mm |

| Main Machine Weight | 7000kg | 6500kg |

Worm grinding wheel gear grinding machine

A gear grinder with a worm wheel is a specific type of gear grinder that uses a worm wheel for grinding processes. Worm grinding wheel is a specialized grinding wheel used for grinding spiral worm gears.

The following are some key features and functions of a gear grinder with a worm wheel:

1. Worm grinding wheel: The machine is equipped with a specific type of grinding wheel called a worm grinding wheel. This grinding wheel is designed for precise grinding of the spiral tooth profile of the worm gear. It has a unique shape and configuration that matches the contour of the worm gear.

2. CNC control: The machine tool adopts a CNC control system, which can accurately control and program the grinding process. This allows the operator to define the required gear specifications, such as tooth profile, pitch, and surface finish.

3. High precision grinding: Gear grinding machines using worm grinding wheels can achieve high-precision worm gear grinding. The combination of professional worm wheel and CNC control system ensures the accuracy and repeatability of grinding results.

4. Multi axis capability: Machines typically have multiple motion axes to adapt to the complex geometric shape of worm gears. This allows grinding of various types of worm gears, including single start and multi start worm gears.

5. Automatic trimming: The machine may have an automatic trimming function for worm grinding wheels. This can ensure that the grinding wheel maintains its shape and cutting performance over time, thereby achieving consistent and high-quality grinding performance.

6. In process measurement: Some gear grinders with worm grinding wheels include in process measurement systems. These systems can measure key parameters during the grinding process, such as tooth profile, tooth pitch, and surface roughness, in order to achieve real-time monitoring and adjustment.

7. Workpiece handling: Machines typically include a workpiece handling system for loading and unloading worm gears for grinding. This can be done manually or through automated systems, depending on the specific machine and application.

8. Software Function: The machine may be equipped with specialized software for gear grinding using worm grinding wheels. This software allows programming of gear profiles, optimizing grinding parameters, and simulating the grinding process.

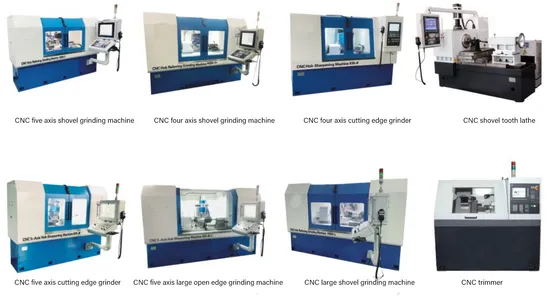

Related products

CNC machines

*CNC worm grinding machine *CNC forming gear grinding machine *CNC rolling cutter shovel grinding machine *CNC cutting edge grinder *CNC grinding wheel repair machine *CNC shovel tooth lathe *Fully CNC high-speed gear hobbing machine

Processing tools

*Measuring instruments *Production equipment *Gear hob *Insert gear hob *Gear hob *Worm gear hob *Involute spline hob *Triangular spline hob rectangular spline hob *Sprocket roller cutter *Circular arc gear hob *Synchronous belt roller cutter

Ever-power is a leading manufacturer and industrial service provider of CNC machine tools and intelligent equipment in the industry. It has established two CNC machine tool production with complete casting production lines, intelligent machine tool assembly lines, and intelligent testing equipment, Equipped with a professional R&D, manufacturing, and sales team, aiming to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.

Relying on strong research and manufacturing capabilities in CNC machine tools, Ever-power not only provides customers with high-quality machine tool equipment, but also integrates and optimizes the industrial chain, providing customers with shared machine tools, intelligent tool cabinets, automation integration solutions, tool health monitoring systems, and other full industry chain equipment and life cycle industrial services. It empowers enterprises in all aspects and achieves industry-leading enterprises with high-quality products and professional services.

Why choose us

Ever-power is committed to providing customers with flexible equipment procurement models such as shared machine tools, machine tool leasing, sales, and rental purchase while connecting the casting, main components, and whole machine assembly industry chain.

1.Thousand machine tools, available for rent in stock 2.Ultra low rent, rent as needed 3.Take action lightly and reduce risks 4.Small investment, large returns 5.Worry free service, lifetime warranty 6.Renting instead of purchasing, flexible model

We have advanced lathe flow assembly lines, standard vertical assembly lines, and assembly lines for medium and large equipment. They are also equipped with constant temperature inspection rooms such as coordinate inspection and precision inspection, as well as high-end inspection equipment such as Zeiss high-performance coordinate measuring machines, Will profilometers, and Renishao laser interferometers, providing the industry with high-quality CNC machine tools and automation integration solutions.

Packaging & Shipping

Ever-power has industry-leading casting production lines such as DISA vertical and horizontal lines, resin sand large, medium and small lines, lost foam production lines, and continuous casting production lines. It can achieve an annual production capacity of 300000 tons of castings and has a complete manufacturing system from casting and forging sheet metal, mechanical processing, heat treatment, packaging and final assembly to warehousing and distribution.

>> Durable Plane Rotary Vibrating Screen with Low Vibration and Easy Maintenance

>> 2022 Heavy Duty Large 2 Person Soft-Spun Polyester Spreader Bar Rope Hammock

>> Factory Price Concrete Mixer Truck 3- 12 Cubic Meters

>> Economical 6 Axis CNC Machining Lathe Swiss Type for Metalworking Slm326m-4

>> SS hydraulic Olive oil press machine/olive oil extraction machine

>> Waste Anti-Wear Hydraulic Oil Treatment Equipment Waste Lubricating Oil Treatment Machine Oil Purifier Reduce Environmental Pollution

>> 4.8"X7.2"/12X18cm Light Green Glossy Decor Wall Tile Glazed Kitchen Ceramic Tile Decoration

>> Tostone Italy Bianco Carrara White Elegant Light Grey Marble Fan-Shaped Mosaic for Home Decor

>> Aluminum Profile Three-Side Flip CNC Drilling and Milling Machine Intelligent and Easy-to-Operate Window Drilling Machine

>> OEM Whole Sale Unique Retro Fashion Customized Acetate Sunglasses for Unisex

>> Spc Click Waterproof Anti-Slip 4mm 5mm Luxury Vinyl Plank Flooring for Project

>> Efficient Green Sand Molding Machine with Featuring Innovative Air Cushion Design

>> CB21013 Police Indonesia Life Jacket

>> High hardness Plastic Pom Delrin Sheet High Wear Resistance

>> Coil Laser Systems Fiber Laser Cutting Machine Combine Advantages of Coil and Laser

>> Custom Logo Fitness Sport Weight Lifting Gloves Men and Women Unisex Hand Workout Gym Gloves Wholesale Customized Gloves

>> 4 Way Clothing Display Rack for Modern Shop Display

>> High Quality Timing Chain for HYUNDAI for KIA TC1915 Engine G4KD/G4NA/G4NB/G4NC with OE No. 243212E000 car parts

>> Ruipuhua Automatic Rusk/Rosca/Biscuits/Cookies Packing Packaging Flow Wrapping Machine

>> Plastic Mixer/Color Pigment Mixer Machine/Powder Granules Vertical Mixer

>> Agricultural Tractor Parts 360 Degree Farm Lawn Rotary Mower Gearbox

>> Double Facer with Heating Plate Drying, Roll Pressing and Cooling Finalizing

>> High Power High Amplitude Fast Speed 20kHz Ultrasonic Titanium Alloy Food Cutter for Automatic Production Line

>> 10.00-20 Steam Jacket Tube Mould with Aluminum Shaping Ring

>> China Supplier Automatic Extrusion Plastic Big Water Tank Container Blow Molding/Moulding Equipment

>> Best Cheap Professional Breathable with Anti-Slip Dots Youth Shock Absorbent Sweat Deodorant Thickened Men Socks Football Sports Socks Soccer Cotton Socks

>> 7 Years Factory Directly Pet Perform Injection Molding Machine

>> Energy Saving Large Output Capacity Waste Wood Chipper Crusher for Biomass

>> Taijia Concrete Test Hammer Rebound Test Resiliometer with Testing Range 10 to 60 Mpa Stroke of Rebound Hammer 75mm

>> Advanced Lsy219-15 Screw Conveyor for Streamlined Material Flow