Efficient Eco Waste Plastic Pet Bottle Recycling Washing Machine Machinery Production Line

| US$5,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

500type~6000type

Material Processed

Plastic Flakes

Plastic Type

PET

Screw

Single-Screw

Automation

Automation

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Machine

PP PE Bottle Washing Line

Capacity

500kg/H-6500kg/H

Power

80~800kw

Solution

Clean Pet Flakes

Material

Carbon Steel or SS304

Machinery Test

Provided

Motor

Siemens or Other Brand

Bearing

Tr Zwz Hrb

Factory

Since 1992

Since 1992

Can Be Customerized

Motor Power

37-132 Kw

Delivery Time

Within 45days

Electrical Panel

Chnt or Other Famous Brand

Inverter

ABB

Certificate

CE

Transport Package

PE Film Strength

Specification

20t~70t

Trademark

Haorui

Origin

Baoding China

HS Code

84778000

Production Capacity

30sets Per Month

Product Description

Product Overview

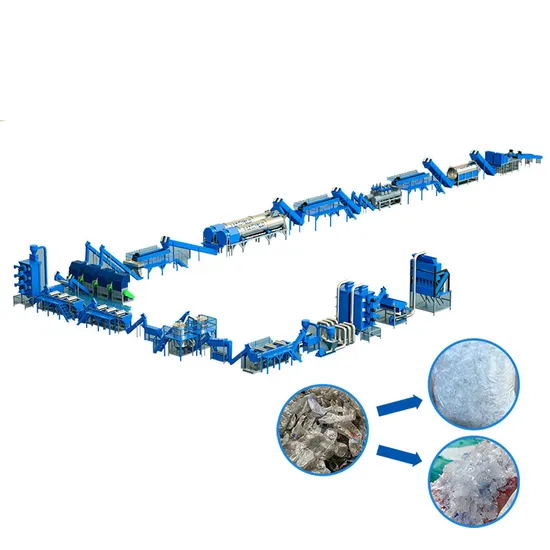

Plastic Recycling Plant/Plastic recycling machine/PP PE Washing Line

usage:Dirty PET bottle into clean and dry PET flakes

Application: PET bottles PP PE

The whole line comes out as clean and dry flakes

There are different offers according to different needs

| type | capacity | power | machine size | weight |

| 500 | 800kg/h | 80kw~150kw | 25m*3m*4m | 20t |

| 1000 | 1500kg/h | 100kw~200kw | 30m*3m*4m | 20t |

| 2000 | 2500kg/h | 200kw~250kw | 60m*5m*5m | 30t |

| 3000 | 3500kg/h | 300kw~350kw | 80m*6m*5m | 40t |

| 5000 | 5500kg/h | 500kw~600kw | 100m*8m*5m | 50t |

| 6000 | 6500kg/h | 600kw~800kw | 120m*8m*5m | 70t |

Details Images

Enough thickness to be stronger

Professional workers carry out processing

Carry out fine production

The special design is to wash more cleanly

Professional workers carry out processing

HAORUI can also produce the PE PE HDPE LDPE washing line and pelletizing machine, crush ,wash and dry the dirty

Other Products

PP pelletizing machine

PP PE HDPE LDPE plastics into clean and dry flakes, then make pellets.

All the production process is completed independently by our factory

Packaging&Shipping

Ensure fast transportation without damage

our advantages

Company ProfileBaoding Haorui Machinery Manufacturing Co.,ltd was established in 1992,is a professional manufacturer and exporter that is concerned with the design,development and production of PET bottle crushing and washing machine, PP PE HDPE LDPE plastic crushing and washing machine, pelletizing machine .There are over 100 technicians in our workshops which covers 20000 square meters. Over 28 years of plastic recycling machines production experience ,enable us to be TOP3 plastic recycling machine factory in China. Our own R&D team make our machine design unique, OEM and ODM service are also welcome. Our main products include bale opener, label remover, plastic crusher, floating tank, screw feeder, high-speed friction washer , hot / cold washer, dewatering machine, pipe dryer and so on.We insist on the principle of "quality is first" and inspect the machine after producing " which make our market more popular in Domestic and over 40 sets of PET bottle washing line(four 6000kg/h capacity in Nigeria ,Ghana etc), PP PE HDPE LDPE washing line ,pelletizing machine were installed in Middle East,Africa,South America,South East, South Asia and so on

Factory

successful case

FAQ

Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hoursQ: How about the rate for removing the labels by Label remover?A: Compressed bottle: more than 96% Un-compressed bottle: more than 98%Q:What's the temperature of steam washer ?A: Usually 80-90ºC ( If the temperature is over 100ºC, the Flake will be roll.so the best temperature is 80-90ºC)Q: What's the moisture after Horizontal dewatering machine?A: About 1.8%. Adopt Swedeen bearing, with bearing layer on the surface of screw bladesfor longer working life.Q: How often are the Crusher blades sharpened?A: After continuous working at 30-40hours, the blades have to be sharpenedQ: How long does it take for changing blades-Remove and install blades?A: Depending on the worker skilled or not. Normally 2-3hours

>> Fully Automatic Customized Mould Egg Tray Forming Machine From China

>> Hot Sale High Quality Vegetables Chinese Shandong Fresh Ginger for Seasoning

>> Automatic CNC Digital Oscillating Knife Curtain Blinds Canvas Round Knife Cutting Machine

>> Personalized New Arrivals Automotive Design Promotional Gift Custom Logo 2D 3D Soft PVC Rubber Keychains

>> Modern American bedroom entry wooden door hotels interior flush solid wood door price simple design door

>> LK-C27B Portable Dental Digital X Ray Radiography Camera Unit Machine 70kv

>> High Output Carton Wood Plastic Lump Box Barrel Drum PE Film PP Woven Bags Ton Jumbo Bag PVC ABS Pipe Medical Waste Heavy Duty Single Double Shaft Shredder

>> Model Y Led Brake Light Double ReverseTaillights For Tesla Model 3/Y Sequential Turn Signal Tail Lights

>> Mirror Chrome Spray Powder Coating Electrostatic Paint

>> Energy saving mini horizontal packing machines plastic spoon packing machine with date printer

>> Adjustable Leg Mount Dolly for Camcorder Tripods with Locking Wheels

>> IP65 Waterproof High Power Warehouse Industrial Lighting

>> Dipped Ca42 SMD Ca45 Low ESR Ca45L Ca55 Tantalum Capacitors

>> Energy Saving Sawdust Wood Pellet Mill Alfalfa Crops Straw Bagasse Pellet Presse Biomass Small Pellet Making Machine

>> High Speed Powder Mixer Machine for PVC Additive PVC Mixer Unit Horizontal Plastic Mixing Machine Pipe Line Blender Hot & Cold Mixer Equipment

>> High Quality Thermos Mugs Tea Lemon Drink Kettle Cold Faucet Water Jug Coffee Pot Thermos

>> PVC Plastic Hoarding Used in Farm

>> Farm Machinery Rotary Cultivator Power Tiller Blade

>> Valvula Pcv PCV Valve for Hyundai Tucson Elantra Getz Accent 26740-21314

>> Shuttering/Marine Plywood/Construction Waterproof Film Faced Plywood for Building

>> CE RoHS Approved 10W/20W/30W/40W/50W/60W/70W/80W/90W/100W Recessed Ceiling Round COB LED Down Light with CREE Chip Lifud Driver

>> Exterior Curtain Wall Decoration Material PE PVDF 4mm Column Aluminum Composite Panel

>> Small Capacity Oil Making Machine for Peanuts Oil Press Machine for Sunflower Oil Processing Machine

>> Creator Fully Digital Tabletop Discussion & Voting Microphone Audio Conference System Gooseneck Microphone

>> HC-A019V Good quality Full Digital Portable veterinary ultrasound scanner for sale/ultrasound veterinary

>> MAICTOP car accessories front grille for Hilux vigo 2012 black front grille

>> Funko Pop Promotional Toys for Customer OEM ODM Orders

>> SM811K01 3BSE018173R1 ABB

>> Filling And Microwave Popcorn Packing Micro Powder Stick Mesh Net Bag Medical Mask Medecine Meatball Meat Milk Packaging Machine

>> Taijia ZBL-P8100 System Pile Integrity Tester Wireless Foundation Pile Dynamic Tester Pile Testing Equipment