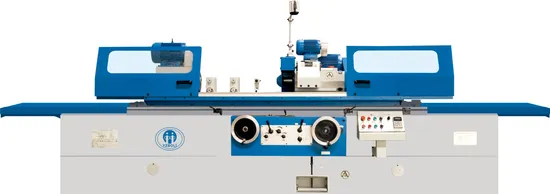

M Series Manual Plane Grinder M618

| US$6,000.00-10,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

M618

Abrasives

Grinding Wheel

Controlling Mode

CNC

Automatic Grade

Semiautomatic

Cylindrical Grinder Type

Surface Grinder

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Product Name

Grinding Machine

Control

Manual/Semi-Auto/Auto

Power

Electrical

Table Type

Normal-Table/Magic-Table

Transport Package

Iron Pallent with Plastic Cover

Specification

200*500mm

Trademark

BOLI

Origin

China

HS Code

84601900

Production Capacity

5000

Product Description

| table size W*L | mm | 150*450 |

| max grinding size W*L | mm | 160*470 |

| max distance from table to spindle center | mm | 450 |

| magnetic chuck size (optional equipment) | mm | 150*400 |

| stroke of table left and right motion | mm | 500 |

| stroke of table cross motion | mm | 185 |

| feed of elevating handwheel | mm | |

| div | mm | 0.005 |

| rev | mm | 1 |

| grind wheel size | mm | 200*13*31.75 |

| spindle roating speed | r/min | 2850(50HZ) |

| power of spindle motor | kw | 1.1 |

| machine weight | kg | 750 |

| package size(worktable dismantled) | cm | 1350*1110*1950 |

The grinding machine is a versatile and efficient tool used for various applications in the manufacturing industry. It is designed to remove excess material or shape workpieces with precision and accuracy. The machine utilizes an abrasive wheel or belt to achieve the desired result. One of the key advantages of the grinding machine is its ability to produce a smooth and polished finish on different materials, including metals, plastics, and ceramics. This makes it ideal for tasks such as surface finishing, deburring, and sharpening tools. The machine's operation involves rotating the abrasive wheel or belt at high speeds, which creates friction against the workpiece. As a result, the excess material is gradually removed, and the desired shape or finish is achieved. The grinding machine can be operated manually or automatically, depending on the complexity of the task. In addition to its versatility, the grinding machine offers excellent precision and accuracy. It is capable of achieving tight tolerances and fine surface finishes, making it an essential tool for industries such as aerospace, automotive, and medical. Furthermore, the grinding machine is designed for durability and reliability. It is built with high-quality components and features a robust construction to withstand the demands of heavy-duty applications. Overall, the grinding machine is an indispensable tool in the manufacturing industry. Its ability to remove excess material, shape workpieces, and produce smooth finishes makes it a valuable asset for any production facility.

>> 60/100mm Deep Drawing Aluminum Flue Pipe Adapter for Gas Boiler

>> Cheap Double Customs Clearance by DHL Rates Shenzhen Shipment to Saudi Jeddah/Myanmar/Nigeria/Kenya Aramex Shipping to Phil

>> Multi Function Survival Pliers Combination Plier (#8505)

>> Stainless steel continuous fertilizer mixer horizontal double shaft animal waste organic fertilizer horizontal paddle mixer

>> Purchase Small 250kg 250 1000 Gallon LPG Propane Gas Tank for Sale

>> Cjm280 Small Multifunctional Lathe, Mini Type Bench Lathe, Metal Working

>> Customized Metal Machining Centre Anodized Aluminum Stainless Steel Titanium Products Milling CNC Spare Parts Machining Services

>> Folding Disabled Handicap Elderly Shower Bench Seat Bathroom Safety Adjustable Shower Chair

>> 12n6.5L-BS Car AGM Separator Battery Plate for Lead-Acid Cell

>> Industrial Chain Hoist 3, 5, 10 Ton with Emulsion Technology

>> Heavy Vt-1100 CNC Metal Lathe CNC Lathe Vertical Machining Machine High Quality CNC

>> Automatic Coffee Chew Packing Filling Machine for Replace Snus Powder Packing Machine

>> 2024 Premium Indoor Bowling Alley Equipment Bowling Lanes for Wholesale Buyers

>> Small mobile gold washing trommel screen machine for mobile gold screening plant

>> Cheap Wood Sawmill Machine, Wood Cutting Band Sawmill

>> Kbpc1010 Bridge Rectifier 10 AMP Single Phase Bridge Rectifier

>> M0008p155 Diesel Common Rail Injector Nozzle, for Injector 5ws40536/8200903034/A2c59513484, Dacia/Nissan

>> HS 2K Topcoat Extra Black 203 OEM Car Paint Refinish High Blackness Good Effect Auto Paint Lacquer Supplier

>> Industrial Automatic Animal Cow Sheep Chicken Poultry Feed Pellet Food Making Machine

>> Z3063X20/1 metal cutting taladro radial arm drill machine with CE

>> High-Quality Dairy Farm Cow Manure Smart Scraper

>> Rtfd-900 ATM POS Thermal Paper Roll Slitting and Rewinding Machine

>> Recliner Zero Manicure Pedicure Human Touch Massage Chair

>> High quality printed bopp laminated 50 kg pp bags

>> Good quality cheap wholesale price Carbonfiber fishingrod fishing tools

>> Goodmi New Arrival Hearing Aids Price List Single One Max Custom Ear Hearing Aids Rechargeable

>> 4040 reverse osmosis membrane shell pressure vessel membrane shell 4040

>> Fashion 8MM Men's Stainless Steel Rings Colorful Groove Beveled Edge Wedding Engagement Ring Men's Anniversary Jewelry

>> CE, ISO, SGS Construction Machinery Concrete Block Making Brick Machine

>> New Generation Automated CNC Contour Cutting Machine for Graphite and Ceramics with High-Efficiency Endless Diamond Wire Saw