Heavy-Duty Premium Hoist Machine Kit for Industrial Casting

| US$100.00-1,000.00 | 100 Pieces (MOQ) |

Basic Info.

Model NO.

3t

Application

Bridge Crane, Small Crane

Type

Electric Hoist

Sling Type

Wire Rope

Lift Speed

2~8m/min

Maximum Lifting Height

12m

Chain Falls

1

Certification

ISO9001:2000, SGS

Condition

New

Color

Yellow

Transport Package

Plastic Bag+Carton+Pallet

Specification

1000mm*1000mm*500mm

Trademark

Changjin

Origin

China

Production Capacity

1000t

Product Description

Product Description| Material | S45C |

| Mould features | Advanced design, Logical structure, High precision, Qualified materials, Long lifetime, Short delivery time. |

| Standard | ASTM&JIS&BSW&ANSI&GB&DIN |

| Certificate | ISO9001,ISO14001,ISO45001,SGS |

| Tolerance | >0-6:±0.1;>6-30:±0.2;>30-120:±0.3;>120:±0.5 |

| Dimension | As per customers' request |

| Processing | Step1: Sand casting/Forging/ Step2: CNC turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, drilling, wire-cutting, EDM, grinding etc. Step3: Surface treatment |

| Surface | Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, etc. |

| Marking | laser marking,Air marking |

| Inspection | material, dimension, heat treatment, hardness, NDT, surface |

| Quality | ISO9001, PPAP control production |

| Lead time | as per clients' requirements |

| Delivery | Express for sample, ocean shipping/air for mass production |

| Our Capabilities | CNC machining, CNC center machining, drilling, milling, turning, grinding, tapping, die casting, casting, forging, stamping |

| Engineering&manufacturing services | R&D process, tooling and gauging design, product design Integrated CAD/CAM system, test and measuring |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer's specific requirements |

Detailed Photos

PRODUCTS SHOWCASE

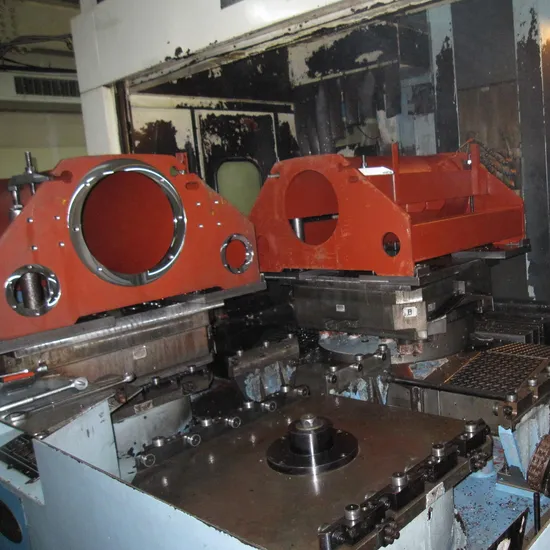

OUR STATE-OF-THE-ART WORKSHOP

PREMIUM CASTING EQUIPMENT

ADVANCED FORGING EQUIPMENT

PRECISION MACHINING EQUIPMENT

RIGOROUS INSPECTIONS

Company Profile

Founded in 2008, Qingdao Xinchangjin Machinery Co., Ltd. has carved a niche in the machinery manufacturing industry. We specialize in the research, development, and production of Crane Hoist Parts, valve accessories, reducers, and other mechanical components. Our company epitomizes modern enterprise by seamlessly integrating R&D, manufacturing, international trade, and marketing services. Leveraging state-of-the-art technology, we ensure superior quality and foster continuous innovation to deliver exceptional machinery products. Our comprehensive services include casting and forging non-ferrous metal raw materials, fabricating finished parts, and providing complete machining solutions.

Packaging & Shipping

For each part developed during the sampling phase, we meticulously design customized packaging to ensure optimal protection and efficient delivery. Our packaging solutions take into account the part's structure, batch size, and specific customer requirements.

Certifications

Our steadfast commitment to quality and customer satisfaction has earned us numerous prestigious certifications. We have enhanced our management systems by adopting ISO9001:2015 for quality, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety.

FAQ

Q: Are you a factory or a trading company?

A: We operate as a distinguished manufacturing factory.

Q: What information is required for a quote?

A: Please provide detailed drawings (PDF/STEP/IGS/DWG...) specifying material, quantity, and surface treatment requirements.

Q: What is the Minimum Order Quantity (MOQ)?

A: The MOQ is flexible based on your needs. We welcome trial orders before proceeding to mass production.

Q: Can I receive a quote without detailed drawings?

A: Absolutely! We can offer precise quotations using samples, pictures, or drafts with detailed measurements.

Q: What is the typical timeframe to receive a sample?

A: Depending on your specific product and requirements, the timeframe typically ranges from 7 to 20 days.

Q: Will my drawings be kept confidential?

A: Absolutely. We prioritize the confidentiality of customer drawings and are prepared to sign a Non-Disclosure Agreement (NDA) if required.

Q: Can I monitor my product's production progress remotely?

A: Yes, we provide a detailed production schedule along with weekly updates, including pictures and videos.

Q: How do you ensure product quality?

A: Our rigorous quality control process includes: Material inspection (surface and dimension checks), Initial production inspection (key dimensions check in mass production), Sampling inspection (quality check before warehousing), and Final inspection (100% inspection before shipment).

Q: What should we do if we receive defective parts?

A: Please send us pictures of the defective items. Our engineering team will promptly find solutions and remake the parts as soon as possible.

>> CNC Beam Drilling Sawing Production Machine FINCM CNC Hydraulic 3d H Beam Drilling Machine For Channel Steel

>> Disposable Medical Anesthesia Face Mask-Factory

>> Hot Sale Carbon Fiber Tube,Carbon Fiber Composite Tube

>> 800h I Type Ship Boat Marine Dock Rubber Fender

>> Famous Brand Smart Power Sp Series Plastic Injection Molding Machine Produce Toys

>> Engine Timing Chain for BMW N62 OEM 7079280 11417527113 TC1214

>> 65g 48g 55g Thermal Paper Cash Register Paper Roll of Packing Machine

>> High Efficiency Vertical (FIFO) Rubber Vulcanizing Molding Injection Machine for Various Products

>> Steel Outdoor Body Building Walking Exercise Equipment

>> Natural Mulberry Fruit Extract Powder for Antioxidant Support Drinking Powder

>> Pnmf Series New Design D2 Material Plastic Grinding Powder Miller Machine

>> CNC Stainless Sink Burnishing Machine

>> Cycjet Lf20f Industrial Fiber Laser Coding Machine for HDPE Color Pipe

>> Arm Weld World Combine Harvester 4lz-6.0p, 102HP Harvester, Cutting Header and Conveyor

>> Anti Theft EAS Pencil Hard Tag for Clothing Security

>> Plastic Retractable Traffic Barricade Extrusion Blow Molding Making Machine

>> Livestock Farming Equipment Automatic Pig Dry/Wet Feeding System/ Drive Unit /Corner

>> China Supplier Customize Tool Crib Security Storage Cage for Warehouse

>> Sapphire Parts for Optics

>> Rhodymenia Palmata Red Algae Flakes

>> Agricultural Mulch Washing Machine LDPE Waste Plastic Washing Machine for Mulch

>> Cq 6232g/36g Lathe Machine with High Precision and Good Price

>> Wayfinding Guest Guidance Wall Mounted Office House Room Name Sign Plaques

>> Jm-900II Custom High Efficiency Full Automatic Injection Molding Plastic Moulding Machine

>> Custom Zippered Makeup & Stationery Storage Bags Felt & Polyester Office Pen & Pencil Case

>> Construction Building Block Machine Plant Qtj4-18 Hollow Block Machine Youtube

>> Foska Letter Size Numberic Plastic Index Divider

>> FOR Chevrolet Captiva 2.4i 16V Catalytic Converter 96629304

>> 2 In1 Filling Capping Machine Liquid Water Skinny Syrup Filling Capping Machine for Small Business Ideas 2024

>> Waste Plastic Pet Bottle Recycling Machine / Pet Flakes Washing Recycling Line Waste Washing Machine