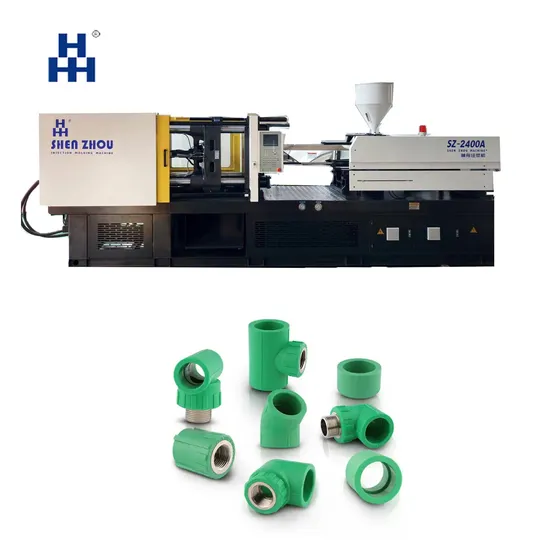

Hot Mould Automatic Plastic Moulding Injection Molding Machine PPR Fittings Sz-2400A

| US$21,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SZ-2400A

Type

Injection Blow Molding

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

CE

Shaping Mode

Injection Mould

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Process Combination Type

Compound Die

Application

Household Appliances, Commodity, Home Use

Runner

Hot Runner

Design Software

Ug

Installation

Fixed

Standard

Hasco

Customized

Customized

Plastic Material

PP/PE

Transport Package

Wooden Case

Specification

SZM

Trademark

ShenZhou

Origin

Jiangsu, China

HS Code

8480790090

Production Capacity

50 Set/Sets Per Month

Product Description

Products Variety

Plastic Bend Pipe and Its Application

Plastic bend pipe, also known as plastic elbow pipe, is a type of plastic pipe fitting that is used to change the direction of a piping system. It is mainly made of high-quality polyethylene (PE) material and adopts a unique molding process to ensure excellent performance in terms of wear resistance, corrosion resistance, and pressure resistance.

The application of plastic bend pipe is extensive, and it can be used in a variety of industries, such as construction, chemical, petroleum, water supply, and drainage systems. Let's take a closer look at some of its applications:

1. Plumbing Systems

In plumbing systems, plastic bend pipes are used to connect straight pipes and change directions for water supply or drainage. They are widely used in residences, commercial buildings, and industrial plants to ensure efficient and safe water and waste transportation.

2. Chemical Industry

In the chemical industry, plastic bend pipes are used as a component of chemical pipelines. They are highly resistant to chemical corrosion and provide reliable performance when transporting highly concentrated acids, alkalis, and other corrosive liquids.

3. Petroleum Industry

In the petroleum industry, plastic bend pipes are used in oil and gas transportation pipelines, as well as in pipelines for fracking and oil well completion. They are highly resistant to oil, acid, and alkali corrosion, and can withstand high-pressure environments.

4. Agriculture

In modern agricultural practices, plastic bend pipes are widely used to facilitate irrigation. They are used as connectors in drip irrigation systems and for laying underground irrigation pipelines.

Plastic bend pipes are a key part of modern piping systems and offer a number of benefits, including low cost, easy installation, and superior performance in demanding environments. Compared to traditional metal pipes, they are more lightweight, flexible, and resistant to corrosion, making them the ideal choice for a variety of applications.

To sum up, plastic bend pipes are essential components in a variety of industries, from plumbing to agriculture and beyond. They are widely used due to their excellent performance, durability, and ease of installation. As new technologies and materials are developed, their application will continue to grow, making them a crucial part of modern infrastructure.

Product Description

Product Parameters

1. Customized mold Information:

| ITEM | UNIT | SZ-1700A | ||

| INJECTION UNIT | ||||

| SCREW DIAMETER | mm | 45 | 50 | 55 |

| SCREW LID RATIO | L/D | 23.3 | 21 | 19.1 |

| THEORETICAL SHOT VOLUME | CM3 | 358 | 442 | 534 |

| SHOT WEIGHT(PS) | g | 326 | 402 | 486 |

| INJECTION PRESSURE | Mpa | 219 | 178 | 147 |

| THEORETICAL INJECTION RATE(PS) | g/s | 142 | 175 | 212 |

| PLASTICISING CAPACITY | g/s | 20.1 | 26.5 | 34.2 |

| SCREW TORQUE | N.m | 1250 | ||

| MAX.SCREW ROTATE SPEED | r/min | 200 | ||

| INJECTION STROKE | mm | 225 | ||

| CLAMPING UNIT | ||||

| MAX.CLAMPING FORCE K | KN | 1700 | ||

| MAX.OPENING STROKE | mm | 460 | ||

| SPACE BETWEEN TIE BARS | mm | 480×480 | ||

| MOULD HEIGHT | mm | 180-500 | ||

| MAX.DAYLIGHT | mm | 960 | ||

| EJECTOR FORCE | KN | 45.2 | ||

| EJECTOR STROKE | mm | 115 | ||

| EJECTOR QUANTITY | 5 | |||

| OTHER | ||||

| PUMP MOTOR POWER | KW | 15 | ||

| PUMP PRESSURE | Mpa | 16 | ||

| HEATING POWER | KW | 13.6 | ||

| HEATING ZONE | 4 | |||

| SIZE | m | 5.3×1.35×1.9 | ||

| NET WEIGHT | t | 5.6 | ||

| OIL TANK CAPACITY | L | 420 | ||

| INTERNATIONAL DESIGNATION | 1700-785 | |||

| Mold information | Content |

| To be discussed | The price is for reference only,the specific price can be negotiated;if there are any other requirements,please state in advance |

| Product material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME,you can choose |

| Cavity material | 45#,50#,P20,H13,718 2738,NAK80,S136,SKD61 etc |

| Runner | cold/hot runner |

| Cavity | multi or single cavity |

| Customized | Per customer request |

| Lead time | about 25 days,depond on reality project |

| Package | standard exported wooden box packed |

| Design software | UG,PROE,CAD,Solidworks |

2. Detail information of bottle cap mold mould steel:

| Mould material | Mould hardness | Mould life |

| P20 | HRC 29-33 | 300000 shot |

| H13 | HRC>43 | 1000000 shot |

| 718 | HRC 30-36 | 500000 shot |

| S136 | HRC 48-52 | 50000 shot |

| 2344 | HRC>48 | 800000 shot |

3. PET Preform mold:

| Name | Mult-cavity preform mould |

| Cavity | 16 24 30 36 .... |

| Material | PET |

| Mould steel | S136 |

| Runner system | hot runner |

| Gate type | valve gate |

| Eject way | stripper |

| Mould running | full automatically |

| Customized | Per customer request |

Why Choose Us

Detailed Photos

Certifications

Company Profile

FAQ

1. Why choose us?

We not only supply the mold, but also the machine and related parts. Port city, convenient transportation.

2. How to ensure the quality of mould?

Debug on the machine before delivery to ensure no quality problems before delivery.

3. What about our after-sales service?

There is a perfect after-sales service system, super long warranty period, any product problems can contact us at any time.

4. About the price?

Higher discount for bulk purchase, price can be negotiated.

5. How long will delivery take after placing an order?

High production efficiency,short delivery time, specific circumstances can be negotiated.

>> Direct Blue 151 Direct Copper Blue 2r for Paper

>> 2024 Camera Skin Scanner 3D Face Scanner Digital Facial Skin Analyzer Face Visia Skin Tester Analyzer

>> Agriculture Equipment Wheat White Sesame Bean Maize Corn Seed Grain Cleaning Machine Cleaner

>> Automatic Feeding Fabric Leather Laser Cutter CO2 Laser Engraving Cutting Machine

>> High Quality Plastic PP PE Film and PP Woven Bags Granulator

>> Chiffon Fabric 100 Pure Silk Fabric Habutai Silk Habotai Fabric Textiles 8mm Mulberry Silk Habotai Fabric

>> High Quality CE Approval Antique Model Golg Car 2+2 Seater Golf Push Cart Electric Golf Cart

>> Mobile Crushing Station with Mobile Jaw Crusher/Cone Crusher

>> High Quality Inflatable Water Slide Amusement Water Park for Sale

>> Charmost Cross-Linked Hyaluronate Gel Ha Acido Hialuronico Hyaluronic Acid Dermal Filler

>> Waterproof Neoprene Armband Phone Case (AC-002)

>> Polyresin Tabletop Fountain with LED Lights

>> Automatic Psb Vertical Centrifuge Milk Cream Separator

>> Automotive Accessory B Class W246 Rubber Support Mounting Mat For Radiator

>> Taijia HT-225 concrete test hammer,buy sclerometer hardness tester concrete test hammer rebound hammer

>> Garage Door Kits Hardware Wholesale Customized Adjustable Garage Door Torsion Tension Spring with Cheap Price Fast Delivery

>> Photocopier Original Toner Cartridge Factory Tk6325 for Kyocera-Machine Kaskalfa 4002I/5000I/5003I/6002I/6003I

>> SGCC/Dx51d/ASTM/0.14-1.5*914-1250mm/Z30-275/PPGI/PPGL/Gi/Gl/Ral Colour/Prepainted/Color Coated/Galvanized/Zinc Coated/Galvalume/Steel Sheet/Roof/Roofing Coil

>> FAW J6 J5 truck parts 1003150-D32-A79F cylinder head gasket Hasing

>> Heracles High Quality H130 0.5ton Small CE Certificate Compact Chinese Hydraulic Battery Electric Wheel Loader for Sale

>> Ck6191L/Ck61100L/Ck61110L CNC Lathe Machine Tool Turning Horizontal Lathe Machine

>> Central air conditioning system regulating valve manual flow regulating valve

>> 0.1L to 3L Pet Bottles Semi Automatic Mineral Water Bottle Making Machine

>> High Quality Corrosion Resistant Vertical FRP Chemical Storage Tank

>> Prefabricated High Quality Aluminum Alloy Polycarbonate Security Shutter Soundproof Casement Window

>> Clear Imp Plastic Eye Glasses Display Cases Mould

>> High- Quality Measuring Tools Ink Fountain Hand Scriber 3PC Chalk Line Rell

>> Anti Electromagnetic Emf/RF Shielding Radiation Proof Radio Wave Protection Maternity/Pregnant Blanket

>> Hot Selling 1 by 11PCS CD DVD Replication Copy Machine

>> AIS China Furniture Sets Design Deco DIY Model Cheap Prices Complete Beautiful Flat Pack Small Modular Wood Kitchen Cabinets Basic Customization Factory Price