Custom Precision CNC Milling Services for Aluminum, Copper, Brass, and Steel

Basic Info.

Condition

New

Certification

ISO9001

Standard

GB

Customized

Customized

Material

Metal

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Tolerances

0.02mm

Size

Customized

Use for

Electrical Contact

Transport Package

Plastic Bag,Carton, or as Per Customer Requirement

Specification

OEM & ODM

Trademark

Sunhua

Origin

Guangdong

Production Capacity

100000pieces/Year

Packaging & Delivery

Package Size

30.00cm * 20.00cm * 10.00cm

Package Gross Weight

5.000kg

Product Description

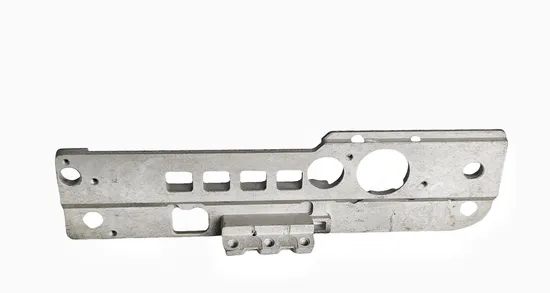

Product Description| Product Name | Metal Processing Machinery Parts CNC Service |

| Product Dimension | Various shapes are available |

| Product Shape | Various shapes are available |

| Processing Type | Stamping |

| Tolerance | ±0.02mm or as per customers' requirement. |

| Material Standard: | ISO, DIN, ASTM, UNS, AISI, JIS, BS, NF |

| Materials available | Stainless Steel, Carbon Steel, Steel, Copper, Brass, Aluminum, Silver, Gold, Chrome, Tin, Nickel, Zinc, Alloy etc. are available. |

| Material Thickness | As per customers' requirement. |

| Surface Treatment/Finish | Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Paint, Powder Coating, Polish etc., |

| Heat treatment capability | Annealing, Normalizing , Nitriding, Tempering ,Carbonitriding, Carburizing and induction hardening etc., |

| Industry Of Use | Electrical |

| Quality Assurance | GB/T19001-2016 ISO 9001:2015, GB/T240001-2016 ISO 14001:2015, RoHS |

| Sample Lead-time | Within 1day for samples available from our stock About 1-2weeks for custom samples |

| Mass Production Lead-time | 3-7 weeks after receiving deposit. |

| Price Terms: | EXW/FOB/CFR/CIF SHENZHAN or any other airport or seaport, China |

| Payment Terms | 30% deposit, balance against B/L copy |

| Modification | Mould modification until the customers satisfy it. |

| Inspection | In-house or third party, all the products are strictly inspected by skilled QC |

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Country of Origin | China (mainland) |

| Main Export Markets | Europe, America, Mid East, Asia, Africa etc., |

| Service Type: | OEM & ODM |

| Business Type: | Manufacturer, Exportor |

| Advantages | Expert in producing OEM parts: metal stamped, machined, deep drawn and sheet metal formed parts with various finishing Our factory is located in Dongguan, nearby Guangzhou and Shenzhen ports, which can save transportation time and cost Employing reliable rockers and utilizing advanced machines: we have a full range of machinery and equipment for punching, welding, CNC, milling and grinding. We also have experienced technicist who are engaged in technical development. Our skilled workers, professional engineers, R and D center and excellent foreign trade team always keep the passion to support our customers |

Welcome to Dongguan Sun Hua Plastic Metal Ltd, your premier destination for unparalleled precision and unparalleled excellence. We are virtuosos in the art of designing and fabricating superior plastic injection molds, die casting molds, and rubber molds. Our expansive range of services includes mass production of parts, meticulously crafted to meet your precise production volume requirements-all at exceptionally competitive prices.

Our distinguished services cater to a diverse array of industries, including: The Automotive Sector: Enhancing vehicle performance with precision-engineered parts. The Powered Tools Industry: Boosting durability and efficiency with our superior components. Home Appliances: Innovatively crafting reliable components for everyday use. The Medical Industry: Providing precision and reliability for critical healthcare applications. New Energy Applications: Leading the way with sustainable and innovative solutions.

Customized CNC Aluminum Parts Supplier - Exquisite Detail in Every Piece.At Dongguan Sun Hua Plastic Metal Ltd, we offer precision-driven CNC engineering solutions. We specialize in custom aluminum, steel, and plastic CNC parts, all meticulously designed to meet the highest industry standards.

| Tool Life Cycles | Extremely High Volume | High Volume | Low Volume |

| 2D Design Drawings | |||

| 3D Design Drawings | |||

| Component ID | |||

| Tool Steel ID | |||

| Cycle Counter | |||

| Spare Ware Parts | |||

| Spare Parts List | |||

| Fully Automatic Operation | |||

| DFM Report | Shall be completed and approved before mold build. All part model changes shall be approved. Report include: KO locations, gate locations, parting line, split lines, mold flow analysis (when required), cosmetic issues, dimensional issues. | ||

| Cpk Requirement | Required Cpk requirement for critical dimensions. | ||

| Cycle Time Target | Mold cycle time shall meet or exceed targets while producing parts within the Cpk requirements. | ||

| Critical Dimensions | Percentage of print tolerance to nominal, mold cavity dimensions of critical dimensions shall be held within. | ||

| Minor Dimensions | Percentage of print tolerance to nominal, mold cavity dimensions of critical dimensions shall be held within. | ||

| Self Lubricating Hardware | Hardware that sees movement should be self lubricating per hardware requirements. | ||

| Certified Tool Steel | Tool steel shall be certified from steel provider. | ||

| Mold Flow Analysis | (when required) | ||

| Mold Dimensional Study | |||

| Part Dimensional Study | |||

Product Details: Comprehensive, Precise, and Tailored to Your Needs. Part 2D drawing, 3D file, or sample picture with exact measurements (3D in IGS, STP format, etc.). Bring your designs to life with our precision-driven expertise. Tooling Steel Specifications: Perfectly Tailored for Unmatched Excellence. Standard Mold Base Options: Versatility, Adaptability, and Performance at Its Best. Runner System Options: Choose between Cold or Hot Runners for Optimal Performance and Efficiency. Mold Cavity Design: Multi-cavity tools with a shut-off gating mechanism for each cavity, ensuring precision and efficiency at all times. Delivery Address Details: Seamless and Timely Distribution Guaranteed. The Strength of SUN HUA: Setting the Benchmark for Excellence.

Expertise in Die Casting Tool Creation: Achieving Craftsmanship at Its Pinnacle. Integrated Solutions for Die-Casting Parts, Plastic Injection Parts, and Toolings: Offering Comprehensive and Cohesive Services. Time-Efficient and Cost-Effective Processes: Maximizing Value While Maintaining Uncompromised Quality. Comprehensive Project Management and Efficient Delivery: Expertly Managing Your Projects from Concept to Completion with Precision. Tooling Making: Delivering Precision, Expertise, and Excellence in Every Tool We Create.

Company Profile

At Dongguan Sun Hua Plastic Metal Ltd, we are the unparalleled experts in OEM die casting parts production, committed to delivering impeccable quality and precision. Since our establishment in 1997, we have relentlessly focused on providing exceptional services, earning us a sterling reputation in the industry.

Key Features: Our expertise spans across model designing, prototype creation, tooling construction, and mass production, ensuring we consistently deliver top-tier results. We proudly collaborate with leading industry brands such as BOSCH, TTI, and BYD. Armed with state-of-the-art technology, including advanced CNC, EDM, grinding machines, and high-capacity die casting machinery ranging from 88 to 2500 tons, we excel in delivering superior quality. Our commitment is to provide comprehensive solutions at highly competitive prices, making us an astute and cost-effective partner. We specialize in tooling fabrication and high-precision CNC machining, ensuring meticulous craftsmanship in every project. We guarantee flawless as-cast quality control and precise measurement correlation to uphold the highest standards. Our streamlined production planning and management ensure maximum efficiency and productivity. Effective project management is the backbone of our operations, ensuring timely deliveries to meet your deadlines. We are dedicated to responsive after-sale services, promptly addressing any quality issues to ensure your complete satisfaction.

Dongguan Sun Hua Company, a trailblazing force in the plastic and hardware industry, made a significant impact at the 2023 American National Hardware Show (NHS). Our company showcased groundbreaking products and innovative technologies, cementing our status as a premier exhibitor in the global market.

Qualification and Honor

FAQ

For any inquiries about our unrivaled products, please explore the detailed information provided below:

Quotation Requirements: To secure the best pricing within just 24 hours, kindly supply us with your 2D or 3D drawings, required quantities, detailed application information, and any available samples. Minimum Order Quantity (MOQ): Our Minimum Order Quantity is flexible to accommodate your needs, and we welcome trial orders to ensure your complete satisfaction. Production Cycle: The production cycle may vary based on the product's dimensions, technical specifications, and order volume. Rest assured, we strive to deliver promptly. Payment Terms: For your convenience, we accept payments via T/T and PayPal, ensuring a seamless transaction process. Production Updates: We provide comprehensive schedules and weekly updates, complete with digital photos and videos, keeping you fully informed throughout the entire production process. Quality Guarantee: Our products are meticulously crafted according to your drawings or samples, ensuring 100% satisfaction with every order. Quality is our top priority. For further information, inquiries, or to connect with us, please send an email or give us a call. We are here to assist you.

Thank you for choosing Dongguan Sun Hua Plastic Metal Ltd for your precision metal part needs. Your trust in our services is greatly appreciated.

>> IC660ELD100A IC660ELB921M IC660ELB912G | GE FANUC MODULE PLC DCS In Stock

>> Oturncnc Metal Turning Machine Machine Ty106 Slant Bed CNC Turning Lathe Optional 3 Axis Type Turning Lathe

>> High Speed DTH Rock Drilling Rig Effective Working

>> High Quality Continuous Working Disc Separator Centrifuge Machine for Small Lime

>> 3D Brick Design Waterproof XPE Wall Foam Sticker

>> TUV Standard 8 Person Commercial Customized Stainless Steel Small Lift Elevator Cabin

>> Hot sale high quality upgrade to full led headlamp headlight plug and play for BMW Mini R56 head lamp head light 2007-2013

>> Poultry Feed Pellet Maker Chicken Feed Pellet Machine Animal Feed Granulator

>> High Speed Jiangsu Province Made Equipment Dirty Pet Drink Bottle Recycling Machine

>> Fashion Anniversary Personalized Logo Promotion Gift Car Accessories Carabiner Leather Keychain for Men

>> 20W LED Downlight IP65 3CCT Fire Rated COB

>> Big Power Dehumidifier 10 Liters to 16 Liters

>> 3axles Heavy Duty Customized Skeleton Semi Trailer

>> Lom Factory Price Cleasing Milk Shampoo Maker Vacuum Emulsified Homogenizer Machine From China

>> Freeshipping 0.2L/Min Misting Cooling System Fog Machine for Patio Cooling and Killing Pest

>> 62t-11400-00 Crankshaft with Bearings for YAMAHA 650 700 760

>> High Efficiency Single Phase Hybrid Inverter 8kw Hybrid Solar Inverter

>> Precision Slits |Custom Slit| Air slit

>> Heat Thermal Transfer Paper Ribbon Printer Coding Hot Ink Rolls

>> MAICTOP car accessories car steering wheel beige black wooden pattern Carbon fiberfor landcruiser prado good quality fj150 2020

>> High Efficiency Spline Shaft Speed Reducer Helical Bevel Gearbox Right Angle Gearmotor

>> Surgical Disposable Nonwoven Nurse Cap/ Bouffant Head Cover

>> 35ton Hand Small Standard Vertical Plastic Injection Moulding Machine

>> 8/9dBi Single Polarization Directional Logarithmic Periodic Antenna

>> Waste Car Truck Lead-Acid Battery Recycling Recycle Line Machine Plant

>> Cheap Price Floating Fish Feed Pellet Extruder Machine Price Floating Fish Feed Mill Pellet Extruder Machine

>> Sheep casing cleaning machine / Hog Casing Cleaning Machine / scraping intestinal machine intestine cleaning machine

>> Stainless Steel Coffee Beans Grains Grinding Machine Corn Grinder

>> Timing Chain Kit for Opel Astra X10XE Z10XE 1.0L 1.2L 1.4L TK1001-12

>> Hammermill Screen for Feed Mill