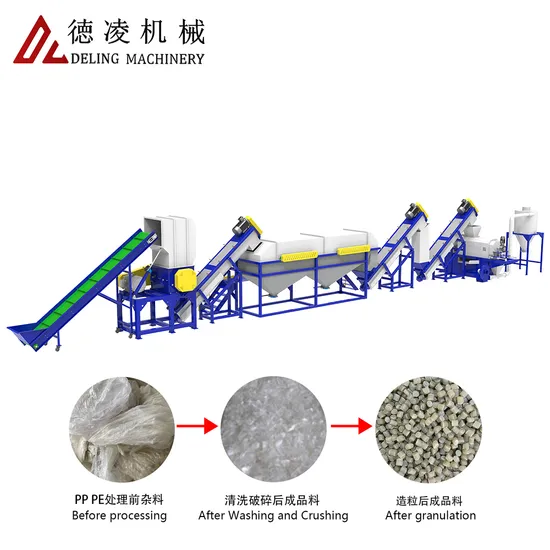

PP PE Film Plastic Recycling Washing Crushing Granulation Production Machine Line Favored Equipment Crusher Shredder Contain Conveyor with Metal Detection

| US$2,999.00-68,580.00 | 1 sets (MOQ) |

Basic Info.

Model NO.

PP PE Recycling Line

Material Processed

Film

Plastic Type

PE

Screw

Double-Screw

Automation

Automation

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Condition

New

Machine Type

PP PE Film Washing Line

Weight (T)

20;Customized

Dimension(L*W*H)

25mx5mx7m;Customized

Automatic Grade

Automatic

Warranty of Core Components

1 Year

Power (Kw)

200

Max.Production Capacity (Kg/H)

3000

Key Selling Points

Automatic

Voltage

380V, 50Hz, 3pH(Customized)

Application

Plastic Bottle Recycling Machine

Machinery Test Report

Provided

Motor

Motor;Wnw

Working Experience

20+Years

Final Products Water Content

Less Than 2%

Transport Package

Land and Sea Transportation

Specification

304 stainless steel

Trademark

DELING

Origin

Jiangsu, China

HS Code

8477800000

Production Capacity

300-3000kg

Packaging & Delivery

Package Size

500.00cm * 500.00cm * 500.00cm

Package Gross Weight

500.000kg

Product Description

Waste PET Bottle & Film

Crushing Washing Recycling Line

We start from de labeling and then sorting. The finished PET bottles are transported by conveyor to the crusher for crushing. The crushed materials are transported by screw to rinsing, and the cleaned materials are sent by screw to the friction machine for friction. The rubbed materials enter the steamer for heating, and after heating and stirring, they are sent by screw to the friction equipment for friction.

After friction is completed, they enter the rinsing machine for two more rinses. After rinsing is completed, they enter the dewatering machine for dehydration, and then enter the distribution system for drying treatment. Finally, the materials are sent to the storage bin, and the entire equipment process is completed.

PP PE Hard & Soft Plastic Mateial

Crushing Washing Recycling Line

PP PE plastic recycling line is an efficient equipment specifically designed for recycling and regenerating PP PE plastics. This production line integrates multiple functions such as crushing, cleaning, drying, and granulation, and can convert waste plastic products into high-quality recycled particles. Its advanced process flow and automation control system not only improve the recycling efficiency, but also ensure the purity and consistency of the regenerated particles. PP PE plastic recycling line is widely used in the plastic recycling industry, helping enterprises achieve green production and sustainable development goals.

The PP PE Film Recycling Washing Line is Suitable for all kinds of waste plastic recycling, such as plastic bags, agricultural films, plastic packing packaging products and so on. The whole line is simple in design, easy to use and widely popular.

| Model | Production Capacity | Total Power | Equipment Footprint |

| DLPPPEWL-300 | 300KGH | about 250KW | 100m2 |

| DLPPPEWL-500 | 500KGH | about 300KW | 150m2 |

| DLPPPEWL-800 | 800KGH | about 320KW | 260m2 |

| DLPPPEWL-1000 | 1000KGH | about 400KW | 380m2 |

| DLPPPEWL-1500 | 1500KGH | about 450KW | 500m2 |

Each customer has different needs, and the specific quotation provided by the salesperson shall prevail

Parts Brand

Prospects and advantages of the plastic recycling industry

1. Environmental protection

Reducing pollution: Plastic recycling can effectively reduce the environmental pollution caused by plastic waste and minimize the damage to land and water resources.

Resource conservation: By recycling and reusing plastic products, the demand for virgin plastics can be reduced, and non renewable resources such as oil can be saved.

2. Policy support

Government promotion: Governments around the world are increasingly focusing on environmental protection and have introduced multiple policies and regulations to encourage and support the development of the plastic recycling industry.

Economic incentives: In some countries, governments provide tax incentives and subsidies to plastic recycling companies to further promote industry development.

3. Market demand

Enterprise demand: With the increasing awareness of environmental protection, more and more enterprises are choosing to use recycled plastics to reduce their environmental footprint.

Consumer preference: The demand for environmentally friendly products has increased, and consumers are willing to pay a premium for products that use recycled materials.

4. Technological progress

Recycling technology: Plastic recycling technology continues to advance, making the recycling process more efficient, cost-effective, and of higher quality.

Innovative applications: The development of new materials and processes enables the application of recycled plastics in more fields, such as building materials, textiles, etc.

5. Global Trends

International Cooperation: Environmental organizations and enterprises worldwide are strengthening cooperation to jointly promote the development of the plastic recycling industry.

Standardization: The development of international standards helps to improve the quality of recycled plastics and promote their circulation and use in the global market.

The plastic recycling industry has broad prospects and significant advantages, which can not only reduce environmental pollution and save resources, but also receive dual promotion from policy support and market demand. With the continuous advancement of technology and the strengthening of global cooperation, the plastic recycling industry will usher in a brighter future.

Q: What is the price of plastic recycling line?

A: This depends on the customer's level of cleanliness of the final material and the required production capacity. We can cals recommend themost effective recycling line combination for the customer based of their budget range

Q: Is it necessary to remove the labelmachine?

A: If there are no labels or caps on the bottles that need to be recycled, or if the customer does not need to remove them, there is no need to remove them, there is no need to remove the label machine

Q: How many labels can be removed by the label removal machine?

A: Processing compressed bottles can remove over 96% of labels and caps, while processing uncompressed bottles can remove over 98%

Q: How often does the blade of the crusher need to be sharpened?

A: Grind at least once a week

Q: How to discharge the dirt and sewage of high-speed fiction cleaning machine?

A: Discharge through the discharge outlet below the machine

Q: What is the most suitable temperature for hot cleaning a steamer?

A: Around 80°C

Q: How to remove residual labels and bottle caps from bottles after the label removal machine?

A: Residual labels and bottle caps can be removed through rinsing tanks and vertical label and cap removal machines

Q: What are the functions of a rinse tank?

A: It can clean the crushed materials, and the residlual label paper and bottle caps willfloat on the water surface when they pass through the rinsing tank, and will not be transported to the next machine

Q: What is the moisture content of the material after passing through the dehydrator?

A: ≤3%

Q: Can a plastic granulator be connected behind the plastic recycling line

A: Yes

Partner with Us for a Sustainable Future in Plastic Recycling

>> Poultry Feed Pellet Maker Chicken Feed Pellet Machine Animal Feed Granulator

>> High Speed Jiangsu Province Made Equipment Dirty Pet Drink Bottle Recycling Machine

>> Fashion Anniversary Personalized Logo Promotion Gift Car Accessories Carabiner Leather Keychain for Men

>> Price Aluminum Door Bathroom Outward Aluminum Entry Casement Aluminium Hinged Doors

>> Outdoor Waterproof IP65 High Power 8W/15W LED Wall Wash Light /LED Flood Light

>> Custom Printed Logo Available Paper Individually Cello Wrapped Toothpick

>> Solid wood lower grey best paint custom standard apartment entrance mdf flush veneer modern wood veneer interior doors

>> plastic packaging detergent powder pouch laundry washing powder detergent bag washing powder packaging bag

>> CNC Drilling Machine for H/U-Beams

>> Chicken House Broiler Laying Hen Factory Price Poultry Farm Automated Cooling Pad Panel Door Exhaust Fans Butterfly Fans Air Inlet Ventilation System

>> Elegant Customizable Jacquard Tablecloth for Stylish Home Decor

>> Ku Band Universal Single LNB for Satellite Dish

>> Chinese Stain Glass Supplier Custom Made Architectural Art Glass Church Doors And Windows Glass Panels Inlaid Stained Glss Sheet

>> High Quality 100% Cotton Tape

>> Estop Same as Makino Factory Custom High-Precision CNC High Speed Machine Center

>> Ffb Processing Machine Palm Oil Mill Palm Oil Production Line

>> Handheld Fiber Laser Welding Machine 1500W Aluminum Copper Galvanized Steel Water Cooled 2025 Automatic

>> Wholesale Custom High-Quality Environmental Protection Cotton Drawstring Bag with Printing Logo

>> CH-Jia High Speed Machine Embroidery with High Quality

>> Object Distance Ratio D: S=12: 1 Dual Laser Digital Infrared Thermometer

>> Pwr-C1-715wac-P= 715W AC 80+ Platinum Config 1 Power Supply Spare

>> Best Sell Vinyl Exam Glove Production Line

>> Ceramic Breast Roll/Central Press Roll for Paper Making Machine

>> Commercial Mini Donut Egg Waffle Stick Taiyaki Mini Pancake Machine Takoyaki Electric Fryer Crepe Maker Machine Gas Electric Automatic Mini Donut Machine

>> Hck 600 Ton Big Plastic Paint Bucket Injection Molding Machine

>> Angle Drilling Machine Tower Structure Fabrication Angle CNC Marking , Shearing and Punching Machine

>> Commercial 8.3mm HDF AC4 Embossed Water Resistant V-Grooved Energy-Saving Engineered Wood Laminate Floor

>> Drill Brush Set Wheel Cleaning Car Wash Brush 3PCS

>> High Quality 41.5*19.5cm Beeswax Foundation Embosser Manual Hive Press for Beekeeping Equipment

>> Outdoor Pet Toys Dog Bath Pool Thickened Durable Bathing Tub Dog Pool