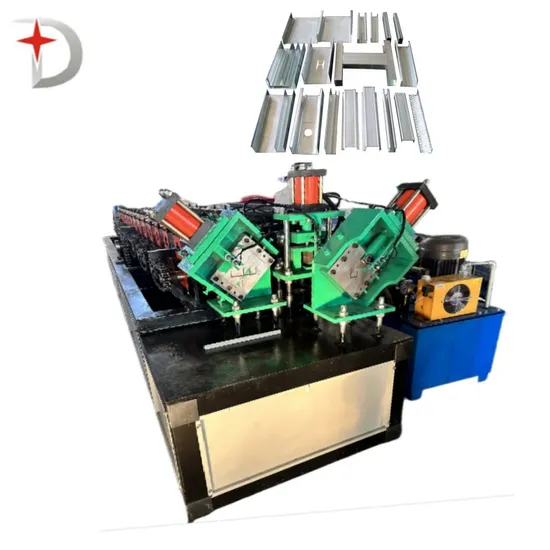

Building Material Double Two in One Ud CD Uw Cw Light Keel Steel Frame Metal Stud and Track Roof Sheet Tile Roll Forming Machinery Making Machine

Basic Info.

Model NO.

request

Tile Type

Colored Steel

Certification

CE, ISO

Condition

New

Customized

Customized

Usage

Roof, Wall

Transmission Method

Hydraulic Pressure

Transport Package

Nude in Container

Specification

CE ISO

Trademark

DIXIN

Origin

Botou Hebei China

HS Code

84552210

Production Capacity

20 Set Per Month

Packaging & Delivery

Package Size

7800.00cm * 1500.00cm * 1400.00cm

Package Gross Weight

3500.000kg

Product Description

Two in one Ud CD Uw Cw Light Steel Metal Stud and Track Roll Forming Machine building material making machineryLight steel keel forming machine with steel as a raw material, by continuous cold rolling molding to produce complex profiles section, type multiple, versatile.Light steel keel molding machine is used to plaster board, gypsum board and other decorative finishes lightweight board made of non-load-bearing walls and roof of the building style decoration, a variety of decorative building roof shape, inside and outside the building wall and ceiling scaffolding base material.

Product Description

Work Follow

Decoiler→Feeding Guide Device→Rolling Forming System→Hydraulic Not Stop Cutting And Punching Device→ Exit Rack1. Component line

| No. | Name | Unit | Qty |

| 1 | Man-made uncoiler | set | 1 |

| 2 | Main machine for roll forming | set | 1 |

| 3 | Control system | set | 1 |

| 4 | Hydraulic system | set | 1 |

| 5 | mold pressing machine | set | 1 |

| 6 | Blade | set | 1 |

| 7 | Receiving table |

| NO | Item | Specification | ||

| Material | Raw material | GI | ||

| Material thickness | 0.3-0.8MM | |||

| Machine | Roller stations | 10-15 stations | ||

| Shaft | Solid ,55mm | |||

| Shaft material | 45# steel with Cr12 chromed , | |||

| Roller material | High grade 45# steel with Cr12 quenched | |||

| Middle plate thickness | 14-18mm | |||

| Machine size | 4.3*0.8*1.0m | |||

| Productivity | 15m/min | |||

| Cutter | Material | Cr12 | ||

| Method | Hydraulic cutting | |||

| Power | Driving way | Chain 1 inch | ||

| Motor | 4KW | |||

| Hydraulic oil pump | 4KW | |||

| Voltage | 380V ,50HZ ,3 Phase | |||

| Control system | PLC | Delta from Taiwan | ||

| Invertor | Delta | |||

| Screen | Touch screen ,Delta | |||

| Encoder | Omron from Japan | |||

| | Language | Chinese ,English or as your need | ||

Detailed Photos

Main Roll forming machine Forming mold: Cr12MoV molding steel, through vacuum quenching heat treatment to HRC60-62 °then grinding the inner

Hole and the end face. The precision machining roller surface with CNC lathe

Shafts material:40Cr steel,CNC lathes,Heat Treatment,hard Chrome Coated

With thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

Main motor and 14 reducers combination driving,about 14-step to form

Main Motor =5.5KW,Frequency speed control

Manual Decoiler 1 Set Un-powered, Manually control steel coil inner bore shrinkage and stop Max Feeding width: 500mm,coil ID range ф460-520mm Capacity:Max 2 Tons*2

Control System Control The Quantity And Cutting Length Automatically Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen , It Can Finish The Production Automatically. Combined With: PLC, Inverter, 10 Inch Touch Screen, Encoder, etc

Technical Strength:

1. We have an experienced expert with young active technical team, which can provide the professional with improved design solutions for our customers , assure that can satisfy various customer's special requirement by cost-effective way. 2. Our engineer always keep on design advanced , humane and most economic resolution for our customers, considering customers long time machine life, low cost maintenance and easy operation, save the cost of labor, maintenance, training for users. At same time, much higher efficiency

Packaging & Shipping

1.roll forming machine need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

After Sales Service

1. The warranty of roll forming machine is two years .after the client receives the machine. Within the Two years,

we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost

Terms of trade 1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 40 workdays

3. Port of loading: port of Tianjin

4. Type of payment: by T/T or by L/C

SOME FAQ

Q1. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ? A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine. Q2. How can we be assured that you will deliver us quality machine with spare parts ? A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality. 2. We can send the technicians to the buyer's factory for the installation of the machine. Q3. What's your payment terms and delivery time? A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery. Q4. Do you have after-sales support? A: Yes, we are happy to provide advice and we also have skilled technicians available across the world. Q5. Do you sell only standard machines? A: No, most of our machines are customized according to customers specifications, also adopt top brand components. Q6. What will you do if the machine is broken? A: We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine. Q7. Can you be responsible for transport? A: Yes, please tell me the destination port or address. we have rich experience in transporting. Q8. How to visit your company? A:1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour). 2)Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour). 3) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

>> Custom Full Color Indonesia Soft Cabretta Leather Golf Sport Glove

>> Youlong OEM Hot Sale 220W 10L/D Indoor Home Dehumidifier For Bedroom

>> Portable Cement Mixer 140L Concrete Mixers

>> Wuxi Good Quality SWC Series Universal Joint Shaft Drive Shaft

>> China Steel bar Rebar Locator Detector Concrete Cover Meter

>> Plastic Pet/PP Strap Thermal Break/Insulation Strip/Tape Packing Belt Extrusion Production Line

>> Plastic Pulverizer PE Miller PP Milling Machine

>> Wide Wheel Heavy Duty Cylindrical Grinding Machine M10200

>> Dental Disposable Inlay Crown Refill Sticks Bonding Sticky Applicator with Wax Tip

>> GAPV factory price moulding body rocker panel door moulding for toyota camry 2012ears 75852-06922 Deluxe Edition

>> 90%New Secondhand Original Japan Top Brand Used PC450 Large PC130 PC220 PC200 PC270 PC300 PC350 PC360 PC400 Engineering-Construction-Machinery Excavators

>> No Stretch Chinese Microfiber Polyester 20mm PV Plush Fabric

>> Decal jumbo roll Adhesive Paper Cutting Machine

>> High-Efficiency Heat Exchanger Heater for Home and Business

>> Woodworking Machinery Automatic V-Slot Audio Photo Frame Gift Box Slotting Machine CNC V Machine

>> Biscuit moulding machine small biscuit making machine with best price

>> Jwell Polyester Pet Recycling Bottle Flakes POY Fiber/Yarn Spinning Machines

>> Disposable Gauze Bandage Medical Surgical Hemostatic Absorbent Cotton Gauze Roll

>> Automatic Metal Processing Surface Grinding Machine Price List

>> 10cbm 10m3 Mix Capacity Sy310c-6W Concrete Mixer Truck 6X4 340HP Left Rudder LHD Cement Mixer Concrete Machinery

>> Swung Drop Hammer Heavy Duty Ventilation Exhaust Fan Air Cooling Fans Poultry Farming Equipment Chicken Pig Cow House Temperature Control

>> Laboratory Vacuum Chemical Stirrer Double Layer Jacketed Glass Reactor

>> 66Galvanized Thickness Gauge|Galvanized layer thickness gauge|Galvanized online thickness gauge|Galvanized coating thickness detector

>> 3cm 4cm 6cm 8cm 10cm Popular Christmas Tree Ornaments

>> Two Pieces Outer or Inner Ring Railroad Heat Treatment Bearings Heating/Quenching Press

>> Electronic Making Kraft Cushion Void Pad Fill Paper Cushion Bubble Machine

>> Perfect Design Dental Equipment China Dental Chair Dental Chair Unit

>> 2021 hot sale Straw rope braiding machine straw rope machine

>> Extinguisher Manufacture CO2 Fire Extinguisher with CE/En3 Certificate

>> Semi Automatic Rotary Microtome