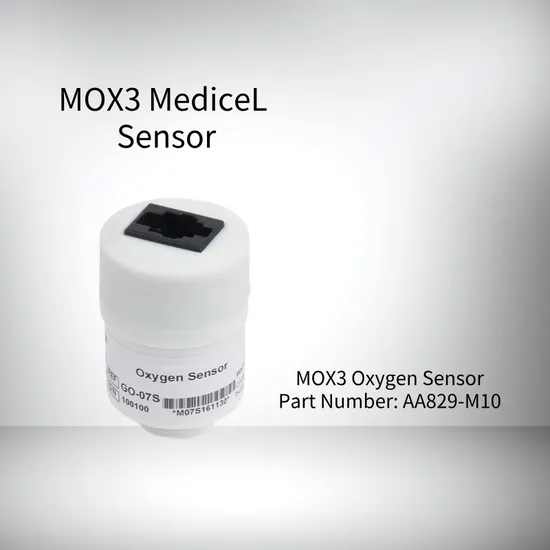

Mox Medicel Oxygen Sensor for Anaesthesia Breathing Machine General O2 Sensor Mox-3

Basic Info.

Model NO.

MOX

Output Signal Type

Analog Type

Production Process

Integration

Material

Metal

Sensitivity

High

Certification

CE

Customized

Non-Customized

Warranty Period

13 Months From Date of Despatch

Range

0-100% O2

Linearity

Linear 0% to 100% O2 (See Note1)

Output in Ambient Air

9 Mv -14 Mv

Repeatability

< 1 % Volume O2 at Constant Temperature and Pressu

Response Time

< 12 S to 90 % of Final Value

Influence of Humidity

-0.03 % Rel. Per % Rh at 25 °c

Operating Temperature

0 °c - +50 °c

Warm-up Time

-20°c to +50°c

Weight

42g

Transport Package

Cartons

Trademark

CITY

Origin

Germany

HS Code

9027100090

Production Capacity

5000PCS/Year

Packaging & Delivery

Package Size

20.00cm * 15.00cm * 10.00cm

Package Gross Weight

0.500kg

Product Description

Product Description Poisoning CiTiceLs are designed for operation in a wide range of environments and harsh conditions. However, it is important that exposure to high concentrations of solvent vapours is avoided, both during storage, fitting into instruments and operation. When using sensors with printed circuit boards (PCBs), degreasing agents should be used before the sensor is fitted. Do not glue directly on or near the CiTiceL as the solvent may cause crazing of the plastic. Intended Use These sensors are designed to be used to monitor the partial pressure of oxygen in anaesthesia (not including xenon), critical care, incubators and general oxygen monitors An 'Instruction For Use' leaflet (RM945 Issue 1.0) is included with each sensor. Stablisation Time Allow at least 15 minutes to stabilise in the instrument before calibration or refer to manufacturer's instructions. Cleaning and Sterilisation In case of contamination the sensor may be cleaned with disculled water and allowed to dry naturally. The sensor is not suitable for sterilisation by steam or exposure to chemicals such as ethylene oxide or hydrogen peroxide. Calibration Interval These sensors are designed to have minimal drift over their useful lifetime. For maximum accuracy however, they should be calibrated before each use. If the Sensor is Dropped If a sensor is dropped, then it should be placed in quarantine for 24 hours and a follow-up check made by a 2 point calibration. Mechanical Installation When installing the sensor, it must only be screwed in hand-tight and a gas tight seal ensured. Spanners and similar mechanical aids may not be used, as excessive force may damage the sensor thread.Company Information

Packaging & Shipping

FAQ

>> 2021 Wubota Combine Harvester for Rice and Wheat Agriculture Machinery Equipment

>> Cm Series 1000/1500/2000 Universal Heavy Duty Metal Horizontal Manual Lathe Machine

>> Compatible Tk130 Toner Kit for Kyocere Fs1300d/1300DN/1350DN/1028mfp/1128mfp

>> M7163 Precision Flat Hydraulic Surface Grinding Machine for metal

>> 21m 69FT Coast Guard Sport Pilot Boat Vessel for Sale Australia

>> High Quality QC3.0 USB Quick Charger Fast Charging Power Adapter 18W Portable Wall Charger EU US Plug phone charger

>> High Temperature Flexible Pex Pipe Cross-Linked Pex Water Floor Heating Pipe

>> Automatic Full Servo Driven Tissue Packaging Machine for Packing Tissue Napkin Paper

>> New Certificate Quality 20W LED Work Light

>> Non Smell High Quality 183*61*0.6cm Non Slip Customized Color Size TPE Yoga Mats Dirt Resistant Double Layer Gym Thickened Fitness Yoga Mat

>> 220/380/440V to 110V 115V 120V 50va to 1kVA Industrial Control Transformer

>> Factory direct sale outdoor camping straight knife fixed blade knife non-slip G10 handle camping tool

>> Cheer Amusement Rainbow Kids Inflatable Bouncy Castle for Bouncing, Jumping

>> CH5125b CNC Single Column Vertical Turning Lathe

>> Luxury Wholesale Custom Logo Summer Children Kids Wear Apparel Boys Girls Tracksuits Clothing Heavyweight 100% Cotton 2 Pieces T Shirt Shorts Sets

>> SASO T3 18000Btu R410 Heat And Cool Airconditioner Wall Split Air Conditioner For Saudi Arabia

>> Small Hole EDM Machine

>> 40kw 50kVA Silent Type 50Hz 60Hz C Ummins 4BTA3.9-G2 Engine Diesel Generator Set

>> Plastic Drum Lifter for Industrial Use

>> Plastic Servo Single Stage Injection Stretch Blow Moulding Machine for Blowing PMMA Bulb Shell Lamp Ball Lampshade

>> Newest floating fish feed machine fish feed pellet machine fish food machine

>> Wooden Case Packed ISO Certified Second Hand Plastic Injection Mould

>> High Capacity Grate Ball Milling Machine for Sale

>> 8 Inch Mini Vehicle HDMI PC Medical Field Computer with Desktop

>> Stainless Steel Small Mill Grinder Herbs Spices Chili Food Industrial Sugar Medicine Power Grinding Machine Pulverizer

>> UT150E Automatic Hang Tag Eyeleting Machine, Hanging Card Rivet Punching Machine

>> Premium 100% Asbestos Free Rubber Sheet Gasket Sealing Sheet 0.5mm-6.0mm

>> High Precision Industry Plastic 3 component 200kgh machine gravimetric blender

>> Custom Three Point Suspension Till Ridging and Film Covering Machine

>> Small Aperture Galvanized Expanded Mesh