Foam Densifier Recycling System: EPS Crusher + Compactor

| US$3,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

300

Material Processed

Foam

Plastic Type

Polystyrene

Screw

Single-Screw

Automation

Automation

Computerized

Non-Computerized

Certification

QS, GMP, ISO9001:2008, CE

Power

Hydraulic + Motor

Output Size

300*300 / 400*400

Hopper

Vertical/Horizontal/Tilt

Motor

Copper Motor

Transport Package

Plywood Box

Specification

300/400

Trademark

Myaid

Origin

China

HS Code

8419899090

Production Capacity

100 Sets Per Month

Packaging & Delivery

Package Size

500.00cm * 150.00cm * 180.00cm

Package Gross Weight

400.000kg

Product Description

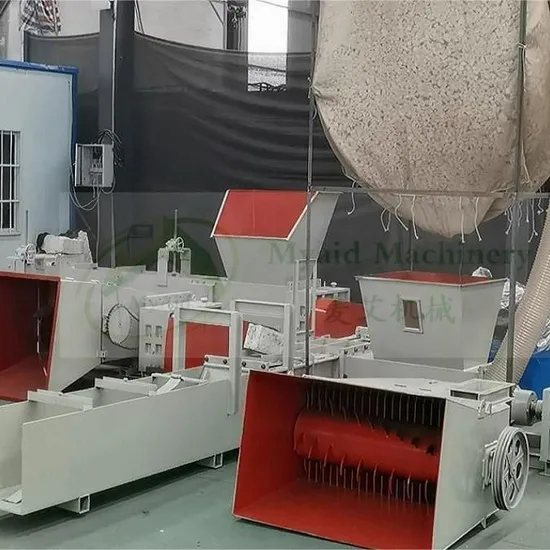

The foam densifier is mainly used to crush and compress EPS foam, EPE PUR EVA and other foam materials.The EPS foam compaction machine is controlled by a PLC-based automatic control system and peripheral circuits, and its performance is quite stable. A larger compression ratio and better quality foam cold pressed blocks can be achieved.

The volume of the material is reduced through the filter on the crusher and compressor, and then the material will fall onto the screw. The main motor will push the material forward through the screw. At the same time, the hydraulic system of the die head is closed to compress the EPS foam material. , these materials will become blocks, and the volume will be reduced by 50 times, making it easier to carry and transport. Machine Advantage

The EPS Compaction Machine can shred and compact EPS polystyrene foam materials of big size and light weight into briquette of high density and small size.It is expensive to transport loose foam materials.Cause 95% of polystyrene beads are air,so it is nessesary to compact it and transport it.

We see foam waste scattered everywhere with small volume,we can drive a truck with the compactor on truck to go everywhere to collect and compact these foam waste.

We have EPS compaction machine with motor and diesel engine powered,we have also hydraulic + screw type compact machine..Buyers can choose from our catalog.

Compact system

To get biggest compact ratio,best compact briquette quality,biggest capacity.users can install a silo on the hopper of comapct machine and a split shredder.Just as the below picture. Machine Application

FAQ

Q: What type of compact machine you have available ?

A: Hopper type with horizontal,vertical and tilt types are available.

Q: What type of powers for compact machine you have available ?

A: Motor type, diesel engine type and hydraulic type of EPS compact machine.

Q: Any screw inside the hydraulic power EPS foam compact machine

A: Yes. Principle

Machine Parameter

| Model No. | 300E | 300H | 300V | 400H | 400V |

| Brick Size | 300*300mm | 300*300mm | 300*300mm | 400*400mm | 400*400mm |

| Capacity | 150kg/h | 150kg/h | 175kg/h | 250kg/h | 300kg/h |

| Diesel Engine | Single cylinder | Single cylinder | Single cylinder | Four cylinders | Four cylinders |

| 18kw | 22kw | 22kw | 48kw | 48kw | |

| L25 | L32 | L32 | 4102 | 4102 | |

| Turn on automatically by battery power or manually by rocker | |||||

| Hopper Size | 830*760mm | 830*760mm | 1100*800mm | 1200*1000mm | 1200*1000mm |

| Machine Size | 3000*1500*1200 | 3000*1700*1200 | 3000*1700*1400 | 4600*1600*1600 | 4600*2800*1400 |

| Machine Weight | 1000 | 1050 | 1050 | 1600 | 1600 |

| Motor Power - optional | 11kw | 11kw | 15kw | 15kw | 22kw |

Company Profile

>> CNC Filament Winding Machine for FRP Pipe

>> Wholesale Empty Aluminum Packaging Tube Aluminum Collapsible Tube

>> Sunglory CNC 3axis Stainless Steel Kitchen Knife Surface Single Side Grinding Machine

>> Professional Manufacturer Produced Hydraulic Hose Crimping Machine Ferrule Crimping Machine Hot Press Machine for Hose

>> Wholesale Popular LED Flash Light Bean Bag Toss

>> Hydraulic Rubber Vulcanizer for Rubber Product Making

>> Ce Approved Blow Molding Machine (for 5-Gallon Pet Bottle)

>> 120 Ton Plastic Barrel Customized Injection Molding Machine

>> Wholesale Women Men UV Protection Anti-UV Jacket Summer Outdoor Rash Guard Windprooof Waterproof

>> Factory Supply Hat Basketball Cap Ironing Equipment Heating Machine Mould Single

>> New Arrivals Professional Outdoor Adjustable Portable in Ground Adjustable Basketball Hoop Stand

>> Jasu Full Automatic High Performance Injection Stretch Blow Molding Machine

>> Refport Laboratory -86c Ultra Low Temperature Portable Freezer with Temperature Control

>> 0.3mm High Selective Solar Absorber for Solar Collector Flat Panel

>> Acrylic Large with 3 Drawer Type Desktop Cosmetics Storage Box

>> Sell 1800mm hammer grab for hard soil conditions for pile foundation/pile grab/pile hammer grab

>> Uking Star Ultra Slim Stable Flat Screen 15"~42" TV Mount Tilt TV Stand

>> 2025 Fuel Injection150cc 168cc 175cc 250cc Chuma 200cc Efi Tank Bws Marshall Salona EEC Gas Scooter Gy6 with EPA Title and Bluetooth for Sale USA Pr Market

>> Fashionable Winter Warm Twisted Flower Striped Beanie with Ribbed Cuff and POM

>> High Precision Universal Horizontal Milling Machine X6036 Knee-Type Horizontal Milling Machine

>> Plug-in Low Voltage Auto Automotive Maxi Blade Auto Fuse for Auto Car Truck

>> Heavy Duty for Industrial CNC Lathe Long Shaft Flat Bed CNC Lathe Machine

>> Taijia digital load cell Stainless Steel Telemetry Load Link Crane Scales and Load Cells Indicators Dynamometers

>> Natural Fruit Extract Powder Food Grade Instant Mango Juice Powder

>> Plastic HDPE 100L 200L Water Barrel Blow Molding Making Machine

>> Fabricated Cement Wall Post Steel Mold

>> Large Supply Various High Quality Embroidered Patches Embroidery Badge

>> China factory Solar AC 5P connectors panel to panel type inverter ac connector

>> Low price micropore athletic elastic sports tape

>> Byloo fishing rod spinning wire wheels pe 7 fishing rod blank spin cast one piece fishing rods