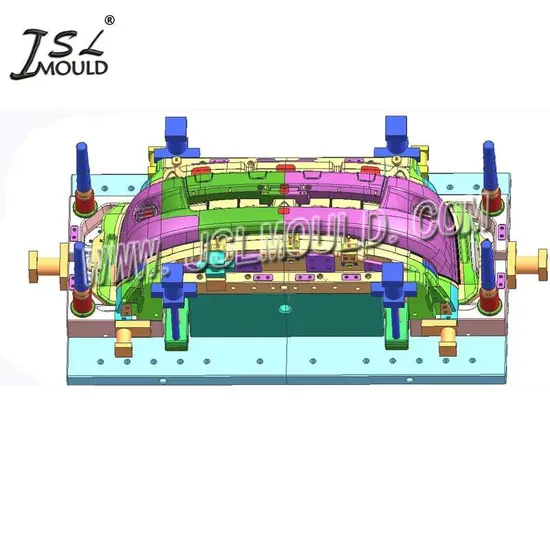

Taizhou Factory Professional Custom Injection Plastic Car Bumper Mold Factory

| US$80,000.00-100,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

MOULD

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

PP

Application

Car

Runner

Hot Runner

Design Software

AutoCAD

Installation

Fixed

Certification

ISO

Standard

DME

Customized

Customized

After-sales Service

1 Year

Mould Runner System

Hot Runner or Cold

Size

According to Customers Requirement

Mould Design Software

Ug, Proe, Solidworks CAD, etc

Mould Base

S50c

Mould Quality Control

in House Professional QC

Mould Operating Mode

Automatically by CNC

Transport Package

High Quality Wooden Case

Specification

DME, HASCO, LKM, etc

Trademark

JSLMOULD

Origin

Huangyan, Taizhou, China

HS Code

8480719090

Production Capacity

350sets/Year

Product Description

Product Name | Taizhou factory Professional Custom Injection Plastic Car Bumper Mold Factory |

| Product material | PP |

| Core&Cavity Steel | 2738 |

| Steel hardness: | HRC34-38 |

| Mould Standard | DME,HASCO,etc |

| Cavity Number | single |

| Injection System | Side Gate with 3 point of hot runner |

| Ejector System | Ejector pin+Ejector block |

| Cycle Time | 80S |

| Tooling lead time | 70DAYS |

| Mould life | 1,000,000SHOTS |

| Quality assurance | ISO9001 |

| Specification | According to client's requirements |

| Our Advantage | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mould are automotic. | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. | |

Main QC Procedure

mould design control

mould steel certificated

mould steel hardness inspection

mould steel electrodes inspection

mould core and cavity steel dimension inspeciton

mould pre assembly inspection

mould trial report and sample inspection

mould pre shipment trial inspection

export mould package inspection.

FAQ:

1.How about your quality control?

We have professional QC team to control mold quality from raw material,machining to the final mould testing parts,as we realize that quality control is the first priority to run business successfully,and the Quality is the life of enterprise.

2.What's your lead time?

For most mold,normally 45 to 60 working days ( not including Chinese official holidays ) after deposit received and mold drawings approved.

3.How to approval samples?

1) You can come to our factory to see the mold testing directly.

2) We could send samples by DHL, TNT, Fedex, and we can send mold running video and molding parts dimension inspection report to you by email.

4.What about your after service?

1 year under normal use procedure,Spare part which is non-man made damaged will be offered for free within one year, and you can contact us at any time if you need help.

>> 5.6 Inch 24W Agriculture Vehicles Flood Spot Tractor LED Light Kits Work Light Tractors Agriculture Headlights LED Lights Tractor Supply

>> White color expanded metal ceiling aluminum expanded mesh ceiling

>> Aluminum Alloy Solar Panel Lift with Anti-Rotation Wire Rope

>> Meat Bowl Cutter with More Sharper Blade

>> Controller Parts K-Silver Ks Tmr Analog Joystick for Playstation 5 Controller

>> Byloo Travel Portable Electronic Luggage Scale 50kg Mini Post Digital Display Home Kitchen Scale Fishing Scale

>> Universal Tool Grinder Automatic Blowing System Turret Punch Grinding Machine

>> 13mm/25mm Hms Sterile Lab Hydrophobic PTFE Syringe Filter

>> Active GPS Antenna Auto GPS Antenna GPS Outdoor Antenna

>> Professional 10X40 Monocular New Model Manufacturer Wholesale with Phone Holder

>> 2/4/5/6/8 Inch PVC Flexible Shower Lay Flat Farm Irrigation Water Pump Drain Duct Hose

>> Versatile Mini LED Flashlight with 3 Modes & Rechargeable USB, Perfect for Camping

>> Micro Bulk Storage Tank/Mini Cryogenic Storage Tank ASME/GB Approved

>> Automatic Rotary Pcu Slipper Injection Moulding Machine

>> High Efficiency 1600t Press Compression Vulcanizing Molding Precision Stable Machine O-Ring Seal

>> Factory Price SFP28 10g 25g Lr 1310nm LC Interface with Ddm SMF 10km 20km SFP28 Optic Trancceiver Module SFP 25g

>> A2/B/PE ACP Production Line Aluminum Composite Fire-Proof Panel Wall Panel Production Line

>> Wholesale Zongshen Three-Wheel Cargo Motorized Truck Trike Tricycle Agricultural Dump Motorcycle Gas

>> High Speed Paper Glass Cup Making Machine 100-120PCS/Min

>> Wooden Toys Wooden Vehicle Toys Preschool Animal Cars Toddler Toy for Kids

>> Hatching Small Poultry Farms Cage Chicken Raising Machine Egg Incubator Hot Sale

>> Wholesale OEM Custom Logo Gym Push Up Designer High Impact Spandex Women's Top Fitness Wear Yoga Sports Bra

>> 2019 Stationary Newest Skin rejuvenation wrinkle removal rf co2 fractional laser beauty equipment

>> Zero Windows Power Supply Smart Home HMI Mmi Raspberry Pi Touch LCD Module with CE-EMC, CE-RoHS

>> SMT JUKI ATF Tape Feeder AF16AS 16MM Feeder E3003706AB0 for pick and place machine

>> Ultra-Reliable No Jamming Interference-Free Data Over 15km Fiber Optic Spool

>> CNC Milling Machine for Metal Cutting and Slotting, Aluminum Auto Tools Changer Vh1160

>> High Speed Vertical CNC Drilling Machine Milling Lathe Machine for H Beams

>> Ab Glue PU Foam Kpu Vamp Hot Pressing Machine

>> Two Roll Open Rubber Mixing Machine for Rubber Factory